Jeep Kl Cherokee Aluminum Coil Spacers - Aluminium Prepainted Coil with PVDF/PE 3XXX

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

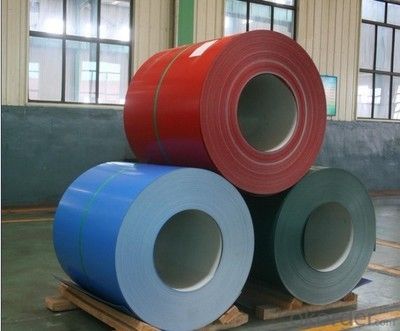

Structure of ALUMINIUM PREPAINTED COIL WITH PVDF/PE 3XXX:

ALUMINIUM PREPAINTED COIL WITH PVDF/PE 3XXX are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of ALUMINIUM PREPAINTED COIL WITH PVDF/PE 3XXX:

High intensity.

Low welding costs.

Outstanding color compatibility after anodizing

Easy to operate. All-position welding.

Excellent corrosion resistance.

Images of ALUMINIUM PREPAINTED COIL WITH PVDF/PE 3XXX:

ALUMINIUM PREPAINTED COIL WITH PVDF/PE 3XXX Specifications:

| Alloy | 1050 1060 1100 3003 3004 3005 3014 3105 3A21 5A02 5005 5052 5083 5251 6061 6063 etc |

| Temper | F O H12 H22 H14 H24 H16 H26 H18 H32 H34 H38 H111 H1112 H116 H321 T5 T6 etc |

| Thickness | 0.02mm - 1.2mm |

| Width | Standard width: 1200mm 1240mm ; Special width:1300mm 1520mm 1570mm 1595mm |

| Diameter | Standar dia: 1200mm ; Interior dia: 150mm 405mm 505mm |

| Weight | 1 T / coil -- 3 T / coil |

| Coating | PE PVDF ACRYLIC |

| Surface | Coated , Mill Finish ,Embossed |

| Color | Ral Color |

| Gloss | 10-90%(EN ISO-2813:1994) |

| Coating Thickness | PE: more than 18 micron PVDF : more than 25 micron |

Coating Hardness (pencilresistance) | More than 2 h |

| Coating Adhesion | 5J (EN ISO - 2409 : 1994 ) |

| Impact Resistance | No peeling or cracking (50kg / cm ,ASTMD - 2794 : 1993 ) |

| Flexibility(T-bend) | 2 T |

| MEK resistance | More than 100 |

| MOQ | 2 T |

| Payment Terms | TT or LC at sight |

| Applycation | Mainly in construction, decoration ,PCB materials, labels, house hold appliance ,lift, cover material ,LCD back panel, refrigeration, air conditioner ,automobile etc |

FAQ:

a: Where is your factory:

Henan Provence.

b:Now which countries do you export your goods?

Now we export to South East Asia,Africa, North America,South America ect

- Q: What are the unique considerations or safety measures to be aware of when using aluminum wire in welding?

- <p>When using aluminum wire in a welding process, special precautions include ensuring proper ventilation to avoid inhaling aluminum fumes, which can be harmful. Use the correct polarity and amperage settings on your welding machine, as aluminum requires direct current electrode negative (DCEN) for most processes. Clean the aluminum surface thoroughly to remove any oxides or contaminants that can affect the weld quality. Protect the aluminum from atmospheric contamination with a shielding gas, typically argon or a mixture, during the welding process. Be cautious of the high thermal conductivity of aluminum, which can lead to faster heat dissipation and may require adjustments in welding technique or parameters.</p>

- Q: What are the different surface finishes available for aluminum coils?

- There are several different surface finishes available for aluminum coils, including mill finish, brushed finish, embossed finish, anodized finish, and painted finish.

- Q: Is it possible to use a crowbar as a tool for opening an aluminum coil?

- <p>While a crowbar can be used to apply force to open various objects, it may not be the most suitable tool for opening an aluminum coil. Aluminum coils can be sharp and using a crowbar could lead to injury or damage to the coil. It's recommended to use gloves and a pair of pliers or a coil cutter specifically designed for handling aluminum coils to ensure safety and avoid damaging the material.</p>

- Q: I planned on making heart shaped pancakes for Valentine's day - is it ok to use aluminum foil as the mold for it? If so, how should I go about it?

- It would make more sense to make a pancake and them cut them out with a heart shaped cookie cutter. I would not use foil on a burner...it will not turn out well. Good Luck

- Q: Can aluminum coils be used in wastewater treatment plants?

- Yes, aluminum coils can be used in wastewater treatment plants. Aluminum coils are commonly used in the construction of heat exchangers, which are essential components in wastewater treatment plants. Heat exchangers are used to transfer heat from the wastewater to the treatment process, helping to optimize the treatment efficiency and reduce energy consumption. Aluminum coils are preferred in some cases due to their excellent thermal conductivity, lightweight, and resistance to corrosion, making them suitable for the harsh environment of wastewater treatment plants. Additionally, aluminum coils are cost-effective and have a long lifespan, making them a reliable choice for use in wastewater treatment facilities.

- Q: Consider the following ionization energies for aluminum:Al(g) → Al+(g) + eI1 = 580 kJ/molAl+(g) → Al2+(g) + eI2 = 1815 kJ/molAl2+(g) → Al3+(g) + eI3 = 2740 kJ/molAl3+(g) → Al4+(g) + eI4 = 11,600 kJ/mol A) Account for the trend in the values of the ionization energies.B) Explain the large increase between I3 and I4.

- aluminum forms an ion by loosing electrons. once an electron is lost, the nucleus attains net positive charge. as a result, the remaining electrons are strongly held by nuclea force of attraction, hence more energy is required to remove them.

- Q: We have all heard the Us saying aluminum and their euro counterparts saying aluminium. I assumed this was just a small difference in culture or location. But, while reading my chemistry book (Chemistry the Central Science 12th) i came across a section saying: Cations formed from nonmetal atoms have names that end in -ium: NH4+ ammonIUM ion, H3O+ hydronIUM ion. So, i have came up with a hypothesis, could it be possible that when the periodic table was coming together, the aluminium was changed to aluminum to allow the rules to work? Thus making aluminum the correct spelling? Give me your thoughts.

- There have been some disputes over element naming. Aluminium is just one of the many. Davy originally named the metal aluminum, after the alum series of minerals. However, people complained about the sound of the word and suggested aluminium instead, to conform with the -ium suffix of many metals (though not all, such as platinum and molybdenum). In 19th-century US, aluminium (with the extra i) was the most used spelling. However, the Hall process of extracting the metal from its ores (an American invention) used aluminum as the spelling, meaning the preferred spelling state-side became aluminum with the omitted letter i. IUPAC states that aluminium is the preferred spelling, but states aluminum as an acceptable variant.

- Q: What are the various categories of aluminum coils based on their characteristics and applications?

- <p>Aluminum coils are categorized based on their thickness, alloy composition, surface treatment, and temper. The main types include: 1) Thickness-based: thin gauge, medium gauge, and thick gauge coils. 2) Alloy composition: 1000 series (99% aluminum), 3000 series (aluminum-manganese), 5000 series (aluminum-magnesium), 6000 series (aluminum-silico-magnesium), and 7000 series (aluminum-zinc). 3) Surface treatment: mill finish, anodized, painted, and coated. 4) Temper: O (annealed), H (strain hardened), W (solution heat treated), and T (thermally treated to various strengths). Each type serves specific industries such as construction, automotive, packaging, and aerospace.</p>

- Q: How do aluminum coils compare to steel coils in terms of strength?

- Aluminum coils and steel coils differ significantly in terms of strength. Steel coils are generally stronger and more durable than aluminum coils. Steel is known for its high tensile strength and ability to withstand heavy loads, making it a preferred choice for applications that require high strength and durability. On the other hand, aluminum coils have a lower strength compared to steel. Aluminum is a lightweight metal with a lower tensile strength, which means it may not be as resistant to heavy loads or stress as steel coils. However, aluminum coils have other favorable properties such as excellent corrosion resistance and high thermal conductivity. The choice between aluminum and steel coils depends on the specific application and requirements. If strength and durability are the primary concerns, steel coils are usually the better option. However, if weight reduction, corrosion resistance, or thermal conductivity are more important, aluminum coils might be the preferred choice.

- Q: Are aluminum coils suitable for pharmaceutical vial caps?

- Pharmaceutical vial caps can indeed be made from aluminum coils. When it comes to pharmaceutical packaging, aluminum is highly favored thanks to its exceptional barrier properties. These properties effectively shield the vials' contents from moisture, oxygen, and other harmful substances. Aluminum coils can be easily molded into caps of various sizes and shapes, accommodating different types of vials. Another advantage is that aluminum is a lightweight material, which makes transportation and handling hassle-free. Additionally, aluminum is resistant to corrosion, ensuring that the vial caps remain intact throughout storage and usage. In summary, due to their barrier properties, versatility, and durability, aluminum coils are a suitable option for pharmaceutical vial caps.

Send your message to us

Jeep Kl Cherokee Aluminum Coil Spacers - Aluminium Prepainted Coil with PVDF/PE 3XXX

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords