Bj's Aluminum Foil Sheets - Prepainted Aluminium Coil with Bekker Paint PVDF

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Coil Prepainted with Bekker Paint PVDF Description:

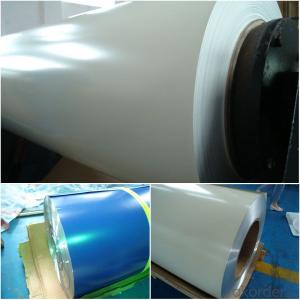

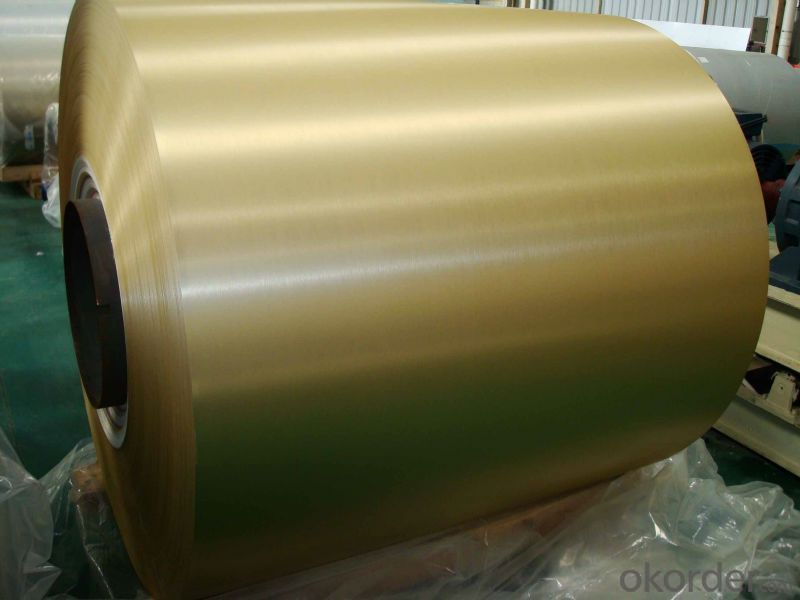

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Coil Prepainted with Bekker Paint PVDF:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of the Aluminium Coil Prepainted with Bekker Paint PVDF:

Aluminium Coil Prepainted with Bekker Paint PVDF Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ Aluminium Coil Prepainted with Bekker Paint PVDF:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South Africa;

- Q: Can aluminum sheets be used for sound barriers?

- Yes, aluminum sheets can be used for sound barriers. Aluminum is a lightweight and durable material that can effectively block and absorb sound waves, making it an ideal choice for soundproofing applications. Aluminum sheets can be installed in various forms, such as solid panels or perforated sheets, to create effective sound barriers in residential, commercial, and industrial settings. The thickness and design of the aluminum sheets can be customized to meet specific soundproofing requirements. Additionally, aluminum is resistant to corrosion, making it suitable for outdoor applications where sound barriers may be exposed to harsh weather conditions. Overall, aluminum sheets provide a cost-effective and efficient solution for reducing noise levels and creating quieter environments.

- Q: Can aluminum sheets be used for architectural facades?

- Yes, aluminum sheets can be used for architectural facades. Aluminum is a lightweight and durable material that is commonly used in construction due to its corrosion resistance and versatility. It can be easily shaped, cut, and formed into various sizes and designs, making it suitable for creating aesthetically pleasing architectural facades. Additionally, aluminum sheets offer excellent weathering properties, low maintenance requirements, and can be finished with different coatings to enhance their appearance and protection against environmental elements.

- Q: What precautions should be taken to ensure safety while installing aluminum sheets?

- <p>When installing aluminum sheets, safety measures include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and hard hats. Ensure the work area is clear of debris and any tripping hazards. Use ladders and scaffolding that are in good condition and set up correctly. Always have a spotter when lifting heavy sheets and use proper lifting techniques to avoid back injuries. Keep hands and feet away from edges and corners to prevent cuts. Ensure all tools are in good working order and use them correctly. Follow all manufacturer's guidelines for installation and adhere to local safety regulations.</p>

- Q: What are the different methods for joining aluminum sheets?

- There are several methods for joining aluminum sheets, depending on the specific application and desired outcome. Some of the common methods include: 1. Welding: Aluminum can be welded using various techniques such as Tungsten Inert Gas (TIG) welding, Metal Inert Gas (MIG) welding, and Resistance Spot Welding (RSW). TIG welding is commonly used for thin aluminum sheets, providing a strong and precise joint. MIG welding is suitable for thicker sheets and offers faster production rates. RSW involves passing an electric current through the sheets, melting the aluminum at the contact points, and then applying pressure to create a solid joint. 2. Mechanical Fasteners: Bolts, nuts, and screws can be used to join aluminum sheets together. They provide a strong and reliable connection that can be easily disassembled if needed. Rivets are another common mechanical fastening method, where a rivet gun is used to secure the sheets by deforming the rivet. 3. Adhesive Bonding: Specialized adhesives designed for aluminum bonding can be used to join sheets together. This method is often used when aesthetics are important, as it provides a clean and seamless appearance. Adhesive bonding also distributes the stress evenly across the joint, reducing the risk of localized stress concentration. 4. Clinching: Clinching is a cold joining process where a punch is used to deform the aluminum sheets, creating a mechanical interlock. This method is quick, cost-effective, and does not require additional materials like fasteners or adhesives. 5. Friction Stir Welding (FSW): FSW is a solid-state joining process that uses a rotating tool to generate friction between the aluminum sheets. The friction heats the material, making it pliable, and the rotating tool then stirs the softened material together to form a solid joint. FSW is particularly suitable for joining thicker aluminum sheets. Each joining method has its own advantages and disadvantages, and the choice depends on factors such as the desired strength, appearance, production rate, and the specific requirements of the application.

- Q: Can aluminum sheets be recycled indefinitely?

- Yes, aluminum sheets can be recycled indefinitely.

- Q: How does the purity of aluminum affect its properties as a sheet?

- The properties of aluminum as a sheet are significantly influenced by its purity. Increased levels of purity generally lead to improved mechanical properties, as well as enhanced thermal and electrical conductivity, and better resistance against corrosion. When aluminum possesses a high level of purity, meaning it contains minimal impurities, it becomes more malleable and ductile. This characteristic makes it easier to shape into thin sheets, rendering highly pure aluminum sheets more appropriate for applications requiring intricate shapes and designs. Moreover, the high electrical conductivity of pure aluminum makes it an exceptional choice for electrical applications, such as wiring and circuit boards. It enables efficient transmission of electricity while minimizing the risk of overheating. Additionally, the thermal conductivity of pure aluminum makes it an ideal option for heat transfer purposes. Aluminum sheets with a high level of purity can effectively dissipate heat, making them well-suited for applications like heat sinks and radiators. Furthermore, the corrosion resistance of aluminum increases with higher levels of purity. Pure aluminum forms a protective oxide layer on its surface, which serves to prevent corrosion and prolong the lifespan of aluminum sheets in various environments. In conclusion, the purity of aluminum directly impacts its properties as a sheet. Increased levels of purity enhance its mechanical properties, as well as its electrical and thermal conductivity. Additionally, it improves its resistance against corrosion, making it more versatile and suitable for a wide range of applications.

- Q: Aren't metals in general (and aluminium in particular) excellent heat conductors?

- Yes aluminium is a good heat conductor, which is why it is used as a heatsink to dissipate heat from electronic components like the CPU in you laptop. The idea of the aluminium stand for your laptop is to raise it up from the desktop surface, allowing air to pass between the gap and extract the heat from the aluminium stand as your laptop heats up with use.

- Q: I wish to purchase an 8' step ladder as well as a medium length extension ladder. What are the pros and cons of aluminum vs. fiberglass?

- The main advantage of fiberglass ladders is the reduction of electric shock from contact with electric wires. A disadvantage of fiberglass ladders is the tendency of fiberglass to crack. The inverse of this applies to aluminum. I bought a Little Giant ladder; it is a 300lb rated aluminum ladder with great stability and can function as a 12' step ladder and a 21' extension ladder. It cost me over $400, but after using it for over a year I would not buy any other kind regardless of the price. This is a solid, well-made ladder with great versatility. It also comes in smaller versions; I think the smallest one collapsed takes up only about 5 feet of space.

- Q: This question asks about the various types of aluminum foil used specifically for the purpose of food packaging.

- <p>Aluminum foil used for food packaging comes in several types, each with specific applications: 1. Heavy-duty foil: Strong and durable, used for roasting meats and baking. 2. Light-duty foil: Thinner and more flexible, ideal for lining baking sheets and wrapping foods. 3. Reynolds Wrap: A brand known for its non-stick and heavy-duty aluminum foils, suitable for a wide range of cooking and baking needs. 4. Aluminum foil rolls: Available in various widths, used for general food wrapping and sealing. 5. Pre-cut aluminum foil squares: Convenient for individual food portions and small wrapping tasks. Each type offers different levels of heat resistance, malleability, and non-stick properties, catering to diverse food packaging requirements.</p>

- Q: How do aluminum sheets perform in terms of weather resistance?

- Aluminum sheets are highly weather-resistant due to their natural oxide coating, which provides excellent corrosion resistance against various weather elements such as rain, snow, UV radiation, and temperature changes. This oxide layer acts as a protective barrier, preventing the metal from further oxidation and degradation. Consequently, aluminum sheets retain their structural integrity and appearance even when exposed to harsh weather conditions for extended periods.

Send your message to us

Bj's Aluminum Foil Sheets - Prepainted Aluminium Coil with Bekker Paint PVDF

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords