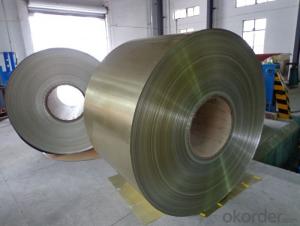

Jeep Kl Cherokee Aluminum Coil Spacers - Color Coated Aluminium Coils for Various Applications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specification of Color Coated Aluminum Coil | |

Alloy | 1050 1060 1070 1100 1200 1235 / 3003 5052 5083 6061 6063 5005 etc. |

Alloy or not | Non-alloy / Alloy |

Temper | O, H112, T4, T5, T6, T651 etc. |

Specification | Thickness: 0.5mm - 500mm |

Width: 600mm - 2200mm | |

Length: 1000 - 6000mm or in coil size | |

Surface | coated |

Application | Heat preservation\ refrigerator\ Furniture\ decorate\ industry\ |

construction\ mould and so on | |

Features | 1.With good plasticity no matter in Cold and Hot condition; |

2. Can be pressed into various shapes of Construction Profile; | |

3. Easy to weld and cold process with good mouldability; | |

4. Can be processed into Sheet, Strip, Tube, Bar, Profile, Forged Piece, etc | |

5. Long life time. | |

MOQ | 3 Ton |

Package | wooden pallets or as customer request |

payment | 30% by T/T as deposit, and the rest 70% balance before loading. |

Delivery time | 15-30 days after receiving the deposit. |

Coating of Color Aluminum Coil

Coating thickness | PVDF >=25micron POLYESTER>=18micron |

Color standard | E < 2 or it is not obvious by eyeballing |

Pencil hardness | > 2HB |

Coating adhesive | not lower than first grade Impact: no any crack (50kg/cm, ASTMD-2794:1993) |

Bend strength | >100 times |

Boiling point: | no any distortion and color change (in the 99 more or less 1 degree water, then cooling 2 hours) |

Corrosive | surface deep in the 5% muriatic acid and 5% NaCL, |

interior deep in the 2% muriatic acid and 2% NaCL, after 48 hours, no change |

Application of Color Coated Aluminum Coil

Main Usage: Aluminium curtaim wall, Aluminium Composite Panel, Aluminium Honeycomb Plate, Ceiling,

Roof, Roller Shutter Door, Garages Door, Furniture, Electronic Industry, etc.

Our services

Main Services:

> Precision aluminum plate

> Casting products

> Forging products

Special Services:

> Alloy selection

> Aluminum machining techniques

> Hot working

> Surface treatment

Our Promise

---High quality stainless steel with reasonable price.

---Wide excellent experiences with after-sale service.

---Every process will be checked by responsible QC.

---Professional packing teams which keep every packing safely.

---Trial order can be done in one week.

---Samples can be provided as your requirements.

- Q: What is the mass of 3.45 moles of Aluminum sulfate?Can u explain how?

- Aluminum sulfate is Al2S3, so you got two atoms of aluminum and three of oxygen. Hence the molar mass of aluminum sulfate is: 2X16 (two times molar mass of oxygen) + 3X32 (three times molar mass of sulfur). Keep in mind that the molar mass of an elements equals its mass number. We have 128 grams per mole or 128 pounds per lb-mol. Since you have 3.45 moles of Al2S3 you just have to do 3.45 times 128 = 441.6 grams

- Q: What’s the standard of tensile strength and ductility of aluminum coil 3003?

- Detailed description can help resolve problems quickly. Performance and status is a related. As aluminum coil is usually semi-hard, the tensile strength is greater than or equals 150, ductility is greater than or equals 12.

- Q: Its got probably 330 horses right now with aluminum heads what do you think it be approx.

- id need a lot more details than you have furnished here to answer your question accurately.....

- Q: What maintenance is required for aluminum coils?

- Maintenance for aluminum coils typically includes regular cleaning and inspection to ensure efficient performance and longevity. Here are some specific maintenance requirements for aluminum coils: 1. Cleaning: Regularly clean the aluminum coils to remove dirt, dust, and debris that can accumulate on the surface. Use a soft brush or a vacuum cleaner with a brush attachment to gently remove any loose particles. Avoid using abrasive cleaners or brushes that can scratch or damage the surface of the aluminum. 2. Inspection: Periodically inspect the aluminum coils for signs of damage or wear. Check for any bent or dented fins, which can restrict airflow and reduce the coils' efficiency. Look for signs of corrosion, such as discoloration or pitting, as this can affect the coils' performance and lifespan. 3. Coil Protection: Apply a protective coating or sealant to the aluminum coils to prevent corrosion and damage from exposure to moisture, chemicals, or harsh environmental conditions. This can help prolong the life of the coils and maintain their performance. 4. Lubrication: If your aluminum coils are part of a mechanical system, such as an HVAC unit, ensure that any moving parts are properly lubricated. This can help reduce friction and wear on the coils, improving their efficiency and preventing premature failure. 5. Professional Maintenance: Consider scheduling regular professional maintenance for your aluminum coils, especially if they are part of a larger system. HVAC technicians or specialized coil cleaning services can provide a thorough inspection, cleaning, and maintenance to ensure optimal performance and identify any potential issues early on. By following these maintenance practices, you can help extend the lifespan of your aluminum coils, improve their efficiency, and prevent costly repairs or replacements.

- Q: What are the potential applications of coil-laminated aluminum coils?

- Coil-laminated aluminum coils have a wide range of potential applications in various industries. They can be used in the manufacturing of automotive parts, such as body panels and interior components, due to their lightweight yet durable nature. Additionally, they are suitable for building and construction purposes, including roofing, siding, and insulation, as they offer excellent corrosion resistance and thermal conductivity. Furthermore, coil-laminated aluminum coils find use in electrical industries for producing transformers, capacitors, and other electrical components due to their excellent electrical conductivity. Overall, their versatility and desirable properties make coil-laminated aluminum coils valuable in numerous applications across different sectors.

- Q: How are aluminum coils priced in the market?

- Aluminum coils are typically priced in the market based on factors such as the current market demand and supply, the cost of raw materials, production and manufacturing costs, transportation costs, and any additional factors that may affect the overall pricing.

- Q: Are aluminum coils recyclable?

- Yes, aluminum coils are recyclable. Aluminum is a highly recyclable material, and it can be melted down and reused to make new products, including coils. Recycling aluminum helps conserve natural resources and reduce energy consumption.

- Q: Are aluminum coils suitable for interior design applications?

- Aluminum coils are indeed a fitting choice for interior design purposes. The versatility of aluminum as a material presents a multitude of advantages for interior design endeavors. To begin with, aluminum possesses a lightweight nature, ensuring ease of handling and installation. This quality proves particularly advantageous for projects necessitating extensive installations or suspended ceilings. Moreover, aluminum coils exhibit exceptional durability and corrosion resistance, guaranteeing extended lifespan and suitability for high-traffic regions. Furthermore, aluminum can be effortlessly tailored and molded to meet specific design requirements, thereby offering limitless design possibilities. Additionally, the material is available in a plethora of finishes, including brushed, polished, or anodized options, which can significantly enhance the aesthetic allure of any interior space. Furthermore, aluminum emerges as a sustainable and eco-friendly alternative, given its easy recyclability and low carbon footprint relative to other materials. All in all, aluminum coils represent a pragmatic and visually pleasing choice for interior design applications.

- Q: Can aluminum coils be custom-made to specific requirements?

- Yes, aluminum coils can be custom-made to specific requirements.

- Q: why is aluminum used for railway lines?thanks x

- If you look at the recent trend in the materials used for railway vehicles, you may find that the mainstream material is lightweight aluminum, which is environmentally-friendly not only for bullet trains, but also for express trains. For commuter trains, stainless steel and aluminum materials are typically used, taking advantage of the merits of both metals.

Send your message to us

Jeep Kl Cherokee Aluminum Coil Spacers - Color Coated Aluminium Coils for Various Applications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords