Aircraft Aluminum Sheets - Aluminum Composite Panel PE or PVDF - Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

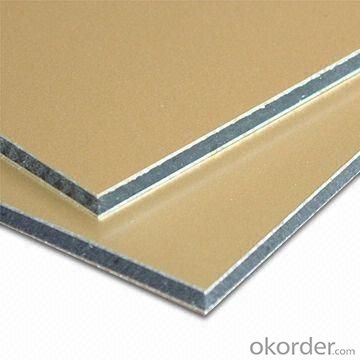

Structure of Aluminium Composite Panel Description:

Aluminum Composite Panel is a composite material made of aluminum and non-combustible mineral filled core. Though the core material does contain a small amount of combustible polyethylene, the main ingredient of the non-combustible mineral filled core does not permit the proliferation of flame and restricts smoke. It is a fire-safe material that passes mandatory requirements for exterior and interior application.It is an ideal material for external claddings, roof of pedestrian passage and other architectural applications.

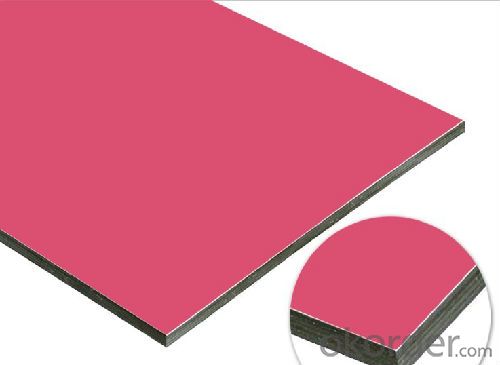

Main Features of Aluminium Composite Panel:

1) Fireproof and water resistant, excellent heat and sound insulation

2) Excellent surface flatness and smoothness

3) Superior weather, corrosion and pollutant resistance

4) Even coating, various colors

5)Super peeling strength

6) Superior impact resistance

7) Lightweight and easy to process

8) Easy to maintain

Images of Aluminium Composite Panel:

Aluminium Composite Panel Specification:

Panel Thickness(mm) | 2mm-8mm |

Aluminium Skin Thickness(mm) | 0.04mm-0.5mm |

Width(mm) | until to 2000mm |

Length(mm) | until to 10000mm |

FAQ of Aluminium Composite Panel

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000㎡.

b. Now which countries do you export your goods?

----Now we export to South East Asia,Africa, North America,South America ect.

- Q: What does exterior wall imitate aluminium paint have? Imitate aluminium plate paint is fluorocarbon paint?

- If not missing the cost or use aluminum plate, because the fluorine content of fluorocarbon metal paint paint factory production lot are not enough, so the warranty 10-15 years is just a pretext, and the construction of the technical requirements for workers is relatively high.

- Q: Can aluminum sheets be an alternative to ceramics in certain applications?

- Yes, aluminum sheets can be an alternative to ceramics in certain applications. Aluminum sheets offer several advantages over ceramics, such as being lighter in weight, more cost-effective, and easier to shape and fabricate. They also have excellent thermal and electrical conductivity properties, making them suitable for applications where heat dissipation or electrical conduction is required. Additionally, aluminum sheets can withstand high temperatures and have good corrosion resistance. However, ceramics still have their own unique properties and strengths, such as higher hardness, better chemical resistance, and superior insulation capabilities, which might be more suitable for certain specific applications. Therefore, the suitability of aluminum sheets as an alternative to ceramics would depend on the specific requirements and conditions of the application in question.

- Q: How does the surface treatment of aluminum sheet affect its appearance?

- The surface treatment of aluminum sheet greatly affects its appearance. Aluminum, in its natural state, has a shiny and reflective surface that can be enhanced or altered through various surface treatments. One common surface treatment for aluminum sheet is anodizing. Anodizing involves creating a protective oxide layer on the surface of the aluminum through an electrochemical process. This treatment can produce a wide range of colors and finishes, from vibrant and opaque to translucent and metallic. Anodized aluminum sheets can have a sleek, modern appearance and are commonly used in architectural and decorative applications. Another surface treatment option is painting or powder coating. These processes involve applying a layer of paint or powder to the aluminum sheet's surface. This treatment allows for customization in terms of color, texture, and finish. Painted or powder-coated aluminum sheets can have a smooth, glossy appearance or a textured, matte finish depending on the desired outcome. This treatment is commonly used in industries such as automotive, aerospace, and construction where aesthetics and durability are important. Further, aluminum sheets can undergo mechanical surface treatments such as brushing or polishing. Brushing involves creating parallel lines on the surface of the sheet using abrasive pads, resulting in a brushed or satin finish. This treatment can give aluminum sheets a contemporary, industrial look. Polishing, on the other hand, involves buffing the surface to a high gloss, mirror-like finish. This treatment is often used for decorative purposes, such as in the production of jewelry or household items. Overall, the surface treatment of aluminum sheet plays a crucial role in determining its appearance. Whether it is anodizing, painting, powder coating, brushing, or polishing, each treatment offers a unique visual effect that can enhance the aesthetic appeal of the aluminum sheet for specific applications and industries.

- Q: i need to know these things please....can aluminium withstand the forces of being in a cargo hold on a air freight, can it withstand extreme temps and to what extent an is it microwavable?? please help me

- No metals are microwavable, they will ruin any microwave oven by producing sparks. Even ceramic plates with a little metallic paint eg of silver will spark. Aluminium on its own has little strength but when mixed with small amounts of eg copper or manganese it aquires great strength while remaining light. In addition it has the advantage of being very resistant to oxidation and corrosion. It is certainly used extensively in aircraft construction. Due to being non toxic it used to make cans for beers, soft drinks (sodas) etc However it doesn't stand up well to high temperatures, its melting point is just at 660 degrees celsius, by comparison for iron it is 1540 and tungsten 3420.

- Q: Trying to find the best aluminum powder I can buy for rocket engines and pyrotechnic (fireworks) uses?

- For okorder (I think there prices are the same as the other high end brands, except Star Molecule is not diluted, and it works better from my experience).

- Q: heating can affect aluminium

- This is science so, if you want specific answers, you must ask specific questions. What type of aluminum are you interested in? What characteristics are important to you? What kind of factors are you talking about? You are right that heating can affect Al. In fact, heating affects, basically, everything, every material we know of and every physical and chemical process that we do and every process that happens in nature. Temperature is important in all of these. There are more than a hundred different commercial aluminum alloys and most of them are available in a variety of different tempers (heat treated conditions). The heat treatment of commercial Al alloys is a very important thing. If you want more specific information, consult your friendly neighborhood metallurgist.

- Q: Can aluminum sheets be painted?

- Yes, aluminum sheets can be painted. However, the process of painting aluminum sheets may require some preparation to ensure proper adhesion and durability of the paint. The most important step is to clean the surface of the aluminum sheet thoroughly to remove any dirt, grease, or corrosion. This can be done using a mild detergent and water or a specialized aluminum cleaner. After cleaning, the surface should be dried completely before painting. To improve the paint adhesion, it is recommended to apply a primer specifically designed for use on aluminum. The primer will create a bond between the aluminum surface and the paint, ensuring better adhesion and longevity of the paint job. After the primer has dried, a suitable paint can be applied to the aluminum sheet. It is important to choose a paint that is compatible with aluminum and provides good adhesion and weather resistance. Acrylic or epoxy-based paints are commonly used for painting aluminum. Before painting, it is advisable to test a small inconspicuous area to ensure that the paint adheres properly and achieves the desired finish. Additionally, it is important to follow the manufacturer's instructions for the specific paint and primer being used, including proper drying times and application techniques. Overall, while aluminum sheets can be painted, it is essential to properly prepare the surface, use suitable primer and paint, and follow the recommended procedures to achieve a durable and aesthetically pleasing paint finish.

- Q: Are aluminum sheets suitable for solar reflectors?

- Certainly, solar reflectors can indeed make use of aluminum sheets. The construction of solar reflectors extensively relies on aluminum owing to its remarkable reflectivity and durability. By virtue of its reflective characteristics, aluminum effectively redirects sunlight onto solar panels or other solar equipment, thereby enhancing energy absorption. Moreover, aluminum is lightweight and resistant to corrosion, making it an excellent choice for outdoor use. Furthermore, its cost-effectiveness and ease of fabrication greatly contribute to its widespread adoption in the solar sector.

- Q: what is the behaviour of Al2O3= aluminium oxide and SiO2= silicon dioxide when heated from room temperature to 1000 degree celcius?

- Aluminium oxide is a metal oxide and here shows it's basic properties. Silicon dioxide is a non metal oxide, so acidic Acid + base ---- salt so aluminium silicate is formed

- Q: What are the different types of surface treatments available for powder-coated aluminum sheets?

- There are several different types of surface treatments available for powder-coated aluminum sheets. Some of the most common options include anodizing, chemical etching, and mechanical finishing. Anodizing is a process that involves immersing the aluminum sheets in an electrolytic solution and applying an electric current to create a protective oxide layer on the surface. This treatment can enhance the durability and corrosion resistance of the aluminum, as well as provide a decorative finish with a wide range of colors. Chemical etching is another surface treatment method that involves applying a chemical solution to the aluminum sheets to create a textured or patterned surface. This process can be used to create unique designs and improve the aesthetics of the material. Mechanical finishing techniques, such as brushing or polishing, can also be used to enhance the appearance and texture of powder-coated aluminum sheets. Brushing creates a brushed or linear pattern on the surface, while polishing creates a smooth and glossy finish. Additionally, there are specialized surface treatments available for specific applications, such as chromate conversion coating for improved adhesion of adhesives or paints, or clear coatings for added protection against UV radiation. Overall, the choice of surface treatment for powder-coated aluminum sheets depends on the desired aesthetic, functionality, and durability requirements of the application.

Send your message to us

Aircraft Aluminum Sheets - Aluminum Composite Panel PE or PVDF - Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords