Bosch Profiles Aluminum A380 High Quality Die Cast

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of A380 Aluminum Die Cast Description:

These are used when the casting alloy cannot be used in hot-chamber machines; these include aluminium, zinc alloys with a large composition of aluminium, magnesium and copper. The process for these machines start with melting the metal in a separate furnace. Then a precise amount of molten metal is transported to the cold-chamber machine where it is fed into an unheated shot chamber (or injection cylinder). This shot is then driven into the die by a hydraulic or mechanical piston. The biggest disadvantage of this system is the slower cycle time due to the need to transfer the molten metal from the furnace to the cold-chamber machine.

2.Main Features of the A380 Aluminum Die Cast:

Drawing: provide by customer, or we design as the sample.

Mold: Design and produce by ourself.

Product Material Option: A360, A380, ADC12, ADC3, AlsSi7Mg, AlSi12, AlSi9Cu3, etc.

SURFACE TREATMENT

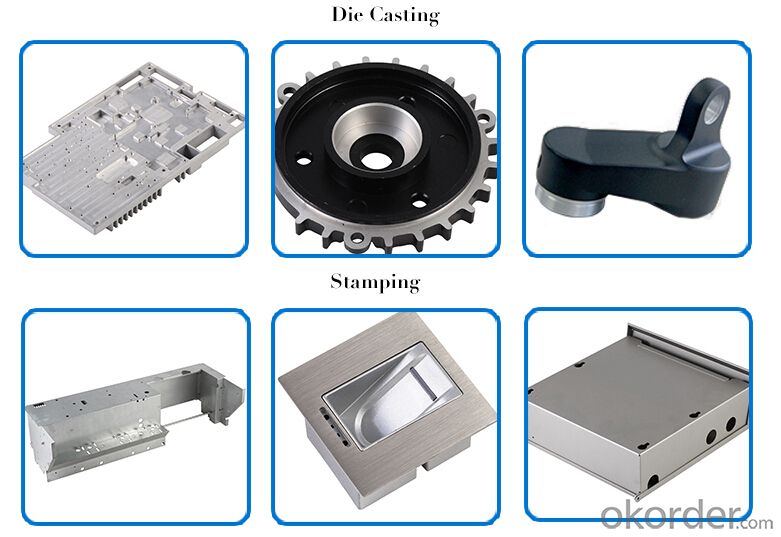

3. A380 Aluminum Die Cast Images

4. A380 Aluminum Die Cast Specification

Process | Material Grade | Weight range | Application |

Investment casting, sand casting, ESR casting Die casting Metal casting

| Iron: Grey iron, Ductile iron Steel: Carbon steel, Alloy steel, Stainless steel Nonferrous metal: Bronze, Brass, Al, Zinc, Ti, etc. | From 0.01Kg to 100 ton | Auto motive, agricultural machines, vessels, toolings, mining , oi l& gas machinery, locomotive industry, aerospace, hardware, contruction, engineering machinery, electrical equipment etc. |

5. RFQ

1).What kind of the materials can be provided?

Product Materials: mainly is Aluminum alloy. But we also can provide other material products for you: like zinc alloy, iron, stainless steel, plastic. Because we are very familiar with them, and better service for you

Mould Materials: H13,3Cr2W8V,4Cr5MoVlsi,SKD61,8407#

According to customers’ requirement

2).What your payment terms?

TT or LC

3).What is the privacy policy of your company?

We respect for all the customers, and make all the customers information confidential. We limit the scope of the information provided to third parties, and we allow its use only the customer permits.

- Q: What are the different shapes available for aluminum profiles?

- There are numerous shapes available for aluminum profiles, including but not limited to T-shapes, angles, channels, square tubes, rectangular tubes, round tubes, and custom profiles.

- Q: Hangzhou aluminum how much money one meter, where can wholesale?

- Decoration materials market, your question is too general profile a variety of non-standard standard and non-standard decoration for many non-standard to open mold and MOQ is non-standard aluminum ingot processing fee plus 5000 yuan I hope to help you. Thank you!

- Q: How do aluminum profiles provide structural stability?

- Structural stability is achieved through the inherent properties and design characteristics of aluminum profiles. The lightweight and strong nature of aluminum makes it an ideal material for constructing different structures. Its high strength-to-weight ratio allows it to support heavy loads while keeping the overall weight of the structure to a minimum. Moreover, aluminum profiles can be designed in various shapes and cross-sections, enabling optimal load distribution and maintaining structural integrity. These profiles can be extruded into shapes like I-beams, T-sections, or rectangular profiles, enhancing the strength and rigidity of the structure. Additionally, aluminum exhibits excellent resistance to corrosion, ensuring the durability and structural soundness of the profiles even in harsh environments. This corrosion resistance eliminates the need for frequent maintenance and extends the lifespan of the structure. Furthermore, aluminum profiles are easily fabricated and assembled, making construction efficient and cost-effective. They can be cut, drilled, welded, or fastened together to create complex structures with precise dimensions. This flexibility in fabrication and assembly allows the profiles to be customized to meet specific design requirements and provide optimal structural stability. In conclusion, aluminum profiles offer structural stability due to their lightweight strength, versatile design options, corrosion resistance, and ease of fabrication and assembly. These properties make aluminum profiles a preferred choice in various industries, including construction, transportation, aerospace, and others.

- Q: Can aluminum profiles be utilized for creating distinctive architectural designs, and if yes, what are the ways to achieve this?

- <p>Yes, aluminum profiles can be used to create unique architectural designs. They are favored for their strength, light weight, and corrosion resistance, which allow for innovative and sustainable building solutions. Architects can use aluminum profiles in various ways: as structural components in curtain walls, as decorative elements in facades, or as supports in roof structures. The profiles can be custom-cut and shaped to fit specific design requirements, and they can be combined with glass or other materials to create a harmonious blend of aesthetics and functionality. Additionally, aluminum's recyclability and low maintenance make it an environmentally friendly choice for architectural projects.</p>

- Q: How much is the 60 series aluminum frame bridge standard size, how much is the size of the fan

- 60 series of insulating aluminum window size 60x53.5, window size 67.8x68.6.Distinguish the bridge aluminum, such as 55 series, refers to the broken bridge aluminum window frame width is 5.5 cm, and the aluminum 70 series refers to the broken bridge aluminum window frame width of 7 cm, the main difference between them lies above the insulation wall thickness and the width of aluminum. The aluminum 55 series and 60 series of wall thickness is the national standard 1.4MM, aluminum doors and windows insulation insulation than 60 series 55 series terms 0.5 cm, aluminum wall thickness, the difference is not, but the 55 series and 70 series of different, one is the 70 series of more than 55 of the width to 1.5 cm wide, the second is the aluminum 70 series aluminum wall thickness is 1.8MM, far better than the national standard.Hollow glass aluminum doors and windows 55 models for 5+12A+5 glass, the middle interval is 12, while the hollow glass interval of 70 series aluminum doors and windows 22, so the aluminum 70 series 55 series of aluminum than sound better. The use of aluminum in the family model 55 is enough, this is the standard engineering materials, which is the most common type of use, if the noise requirements higher, it can be considered by the German red card 70 series of ten sealing design, especially along the street district is relatively high requirements on the sound. Is the best choice.

- Q: Are aluminum profiles suitable for use in the mining industry?

- Yes, aluminum profiles are suitable for use in the mining industry. Aluminum is lightweight, corrosion-resistant, and durable, making it ideal for various applications in mining equipment and infrastructure. It offers strength and stability while being easy to transport and install. Additionally, aluminum profiles can withstand harsh environmental conditions and are resistant to chemicals commonly found in mining operations.

- Q: Are aluminum profiles suitable for mass production or large-scale projects?

- Yes, aluminum profiles are highly suitable for mass production or large-scale projects. Aluminum is a lightweight and durable material that offers numerous advantages for industrial use. Its strength-to-weight ratio is excellent, allowing for the creation of lightweight but robust structures. This makes it easier to transport and assemble large-scale projects while maintaining structural integrity. Aluminum profiles can be easily extruded into various shapes and sizes, providing flexibility in design and accommodating different project requirements. The extrusion process is highly efficient, making it cost-effective for mass production. Additionally, aluminum is a highly recyclable material, making it environmentally friendly and sustainable for large-scale projects. Moreover, aluminum profiles offer excellent corrosion resistance, which is crucial for projects in outdoor or harsh environments. They can withstand extreme temperatures, UV radiation, and moisture, ensuring long-term durability and reducing maintenance costs. The versatility of aluminum profiles also allows for easy integration with other materials, such as glass or composite panels, enhancing the aesthetic appeal and functionality of the final product. Overall, the versatility, strength, lightweight nature, cost-effectiveness, and environmental sustainability of aluminum profiles make them an ideal choice for mass production or large-scale projects.

- Q: Are aluminum profiles suitable for exterior cladding systems that need to withstand fire?

- <p>Yes, aluminum profiles can be used for exterior cladding systems that require fire resistance. Aluminum is a non-combustible material, which means it does not support combustion. However, it's important to note that while aluminum itself doesn't burn, it can melt at high temperatures. To enhance fire resistance, aluminum profiles can be coated with intumescent paint or used with fire-resistant materials in the cladding system. These measures can help to slow the spread of fire and protect the structure. Always ensure compliance with local building codes and fire safety regulations when selecting materials for fire-resistant applications.</p>

- Q: Explain the various methods used to connect aluminum profiles in construction.

- <p>In building construction, aluminum profiles can be joined together using several methods: 1. Mechanical fastening, which includes bolts, screws, and rivets. 2. Welding, which permanently fuses the profiles together using heat. 3. Adhesive bonding, which uses specialized adhesives to bond the profiles. 4. Clipping or snap-fit connections, which use spring-loaded clips or interlocking parts. 5. Mortise and tenon joints, where one profile has a projection that fits into a hole in another. 6. Socket and pin connections, where a pin is inserted into a socket on the profiles. These methods can be used individually or in combination, depending on the specific requirements of the construction project.</p>

- Q: What are the specific requirements or considerations when using aluminum profiles in the construction or design of swimming pools and spas?

- <p>Yes, there are special requirements for using aluminum profiles in swimming pools and spas. These include corrosion resistance to withstand chlorinated water, which is common in pools and spas. Profiles must be made of marine-grade aluminum to prevent rust and ensure longevity. They should also be able to withstand high humidity and temperature fluctuations. Additionally, profiles need to be non-slip and easy to clean to maintain safety and hygiene. The design should also consider structural integrity to support the weight of the pool or spa structure and any associated equipment.</p>

Send your message to us

Bosch Profiles Aluminum A380 High Quality Die Cast

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords