6061 Aluminum Coils for Sale - 1200 Aluminum Alloy Coil H112 Temper

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

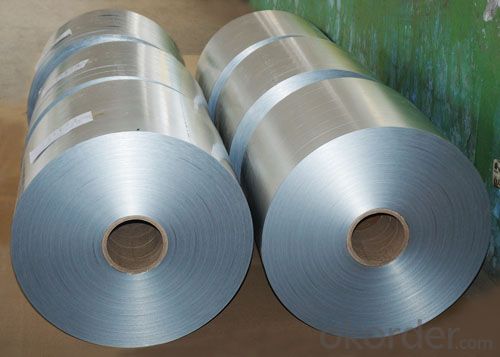

Aluminum Coil 1200 Aluminum Alloy Coil H112 Temper

1050 1060 1070 1100 1235representative series aluminum plate is also known as pure aluminum, in the series in 1xxx series belongs to all the alumina quantity of a maximum number of series. Purity can achieve 99.00% above

3xxx series aluminum represents 3003 3004,3005, 3 A21 primarily. And can be called in the 3xxx series aluminum antirust aluminum production process more outstanding. The 3xxx series aluminum plate is by manganese as the main component. Content at 1.0-1.5 between. Is a rust-proof function better series. Conventional application in the air conditioning, the refrigerator, such as car in damp environment.

6xxx series represents 6061 mainly contain magnesium and silicon of two elements, so focused on the 4000 series and the advantages of the 5000 series 6061 is a cold treatment aluminum forging products, apply to fight against corrosion, oxidizing demanding applications.

Description

item | 1050 1060 1100 3003 Aluminum coil | |

Standard | GB/T3190-2008,GB/T3880-2006,ASTM B209,JIS H4000-2006,etc | |

Material | 1060,1050,1100 3003,3103,3004,3005,3105 5052, 5454,5754 | |

Size | Thickness | 0.5mm-3.5mm |

Width | 800-1500mm | |

Weight/Roll | About 1.5MT/3MT | |

Quality control | Mill Test Certificate is supplied with shipment, Third Part Inspection is acceptable. | |

Surface | Bright, polished, hair line, brush, checkered, embossed, etc | |

Trade terms | Price term | ,FOB, CNF, CIF, etc |

Payment Term | TT,L/C | |

MOQ | 2MT | |

20 GP Capacity | About 20-25MT | |

Delivery time | 1.The products will delivery immediately after receiving the payment. 2.According to the order quantity, prompt delivery. | |

Export to | Ireland,Singapore,Indonesia,Ukraine,Spain,Canada,USA,Brazil,Thailand,Korea,Iran,India,Egypt,Kuwait, Oman,Viet Nam, South Africa, Dubai, Russia, etc | |

Package | Stick blue film→plastic film→waterproof paper→1~2 tons on a export standard pallet(corner protection) | |

Application | 1)Further making utensil.2)Solar reflective film3)The appearance of the building4)Interior decorating:ceilings,walls,etc.5)Furniture cabinets6)Elevator decoraction7)Signs,nameplate,bags making.8)Decoration inside and outside the car9)Household appliances:refrigerators,microwave ovens,audio equipment,etc.10)The consumer electronics:mobile phones,digital cameras,MP3,etc. | |

- Q: Can aluminum coils be used for pharmaceutical packaging?

- Certainly, pharmaceutical packaging can make use of aluminum coils. Aluminum is widely preferred for such purposes owing to its numerous advantageous properties. Notably, its lightweight nature, resistance to corrosion, and exceptional barrier properties render it exceptionally suitable for safeguarding pharmaceutical items against external elements like moisture, oxygen, and light. Moreover, aluminum coils can be conveniently fashioned into various shapes and sizes, thereby offering flexibility to meet diverse packaging requirements. It is also worth mentioning that aluminum is both non-toxic and non-reactive, thereby guaranteeing the safety and overall quality of pharmaceutical products.

- Q: It's time for a new bike and I don't know enough about the pros and cons of aluminum vs. carbon fiber. I can get a low-end carbon bike or a high-end aluminum for about the same price, so the budget is not really a major issue. Any opinions would be appreciated.

- Just a little personal story here. I recently bought a new old stock Carbon Giant TCR Limited at a great price, did some wheel upgrades and the like then took it out for a ride. The difference between that bike and my Colnago Aluminum Dream (still have it) was amazing. The whole ride quality, smoothness and climbing ability of the CF bike was supierior to that of the Colnago. Or was it just the novelty of the newness? Sure the two have different geometries and gearing but I feel so much more comfortable on the CF giant for long (over 50 mile) rides then the Al. Colnago. Test ride them both, you'll see.

- Q: What are the potential drawbacks or limitations of using aluminum coils?

- Using aluminum coils has several potential drawbacks and limitations. Firstly, aluminum is a softer metal compared to materials like copper or steel, making the coils more susceptible to damage such as denting or bending, especially in high-impact environments. Additionally, aluminum is prone to corrosion, especially in harsh or corrosive surroundings, which can negatively affect the coils' performance and lifespan. Another limitation of aluminum coils is their lower thermal conductivity in comparison to copper coils. This means that aluminum coils may not transfer heat as efficiently, resulting in decreased cooling or heating performance in certain applications. Moreover, the lower thermal conductivity may lead to higher energy consumption as the system needs to work harder to achieve the desired temperature. Furthermore, when aluminum coils are used in HVAC systems, compatibility issues can arise with specific refrigerants. Aluminum can react with certain refrigerants, causing corrosion or other chemical reactions that could compromise the coils' performance and longevity. Therefore, careful consideration and compatibility testing are necessary when selecting a refrigerant to use with aluminum coils. Lastly, the cost of aluminum coils can be higher compared to other coil materials. Although aluminum itself is relatively inexpensive, the manufacturing process for aluminum coils can be more complex and costly, impacting the overall product cost. Despite these drawbacks, aluminum coils are still widely utilized in various industries due to their lightweight nature, good electrical conductivity, and resistance to certain types of corrosion. However, it is crucial to thoroughly evaluate the specific application, environment, and requirements before choosing aluminum coils to ensure they are the most suitable option.

- Q: What style of womens Oakley sunglasses come in aluminum? I need a tough pair and would like interchangeable lenses option also.

- You can go to this website to buy it.My friends have bought the oakley sunglasses from this site,so you can rest assured,it is the real website.The products are nice replicas,they are of high quality and also lower price.I believe you can buy the one you want from this site.

- Q: How do aluminum coils contribute to energy-efficient HVAC systems?

- The role of aluminum coils in making HVAC systems energy-efficient is crucial. Firstly, aluminum is an exceptional heat conductor, enabling efficient heat transfer between different areas. In HVAC systems, aluminum coils are utilized in the condenser and evaporator units to facilitate the heat exchange process. In the condenser unit, the hot refrigerant vapor from the compressor passes through the aluminum coils. Due to the coils' high thermal conductivity, the heat is rapidly dissipated to the surrounding air, allowing the refrigerant to condense and release the heat energy. This effective heat transfer enhances the cooling performance of the HVAC system. Similarly, in the evaporator unit, the aluminum coils are responsible for absorbing heat from the indoor air. The cold refrigerant inside the coils absorbs the heat, resulting in the air cooling down. Ultimately, the cooled air is circulated back into the room. The superior thermal conductivity of aluminum enables quick heat absorption, improving the overall cooling efficiency of the HVAC system. Moreover, aluminum coils offer an energy-saving advantage by being lightweight. Compared to traditional copper coils, aluminum coils reduce the overall weight of the HVAC system. This weight reduction leads to lower energy consumption by the system's fan and compressor, as they require less effort to move the air and refrigerant throughout the system. Additionally, aluminum coils are highly resistant to corrosion, which prolongs the lifespan of the HVAC system. Corrosion can hinder heat transfer efficiency and result in refrigerant leaks, causing the system to consume more energy. By utilizing aluminum coils, the risk of corrosion is minimized, ensuring long-term energy efficiency. In conclusion, aluminum coils enhance the energy efficiency of HVAC systems by improving heat transfer efficiency, reducing overall system weight, and providing corrosion resistance. These factors collectively contribute to the effective operation of HVAC systems, consuming less energy while maintaining optimal indoor comfort.

- Q: How are aluminum coils transported and packaged?

- Aluminum coils are typically transported and packaged using wooden crates or pallets. The coils are securely strapped or bundled together to prevent movement during transit. They are then loaded onto trucks or shipping containers for transportation, ensuring they are well-protected to avoid any damage or deformation.

- Q: Can aluminum coils be used in extreme temperature conditions?

- Yes, aluminum coils can be used in extreme temperature conditions. Aluminum has a high thermal conductivity and is resistant to corrosion, making it suitable for various temperature extremes. Additionally, aluminum's low melting point allows it to withstand high temperatures without deforming or losing its structural integrity.

- Q: Can aluminum coils be used in roofing or cladding systems?

- Yes, aluminum coils can be used in roofing or cladding systems. Aluminum is a popular choice for these applications due to its lightweight nature and excellent corrosion resistance. Aluminum coils are commonly used in roofing and cladding systems to create a durable and long-lasting solution. They are often coated with a protective layer or finish to enhance their performance and aesthetics. Additionally, aluminum coils are easy to work with, making installation and maintenance convenient. Overall, aluminum coils are a suitable choice for roofing or cladding systems as they offer various advantages and meet the requirements of these applications.

- Q: Are aluminum coils more cost-effective compared to other materials like copper?

- Yes, aluminum coils are generally more cost-effective compared to copper coils. Aluminum is cheaper and more abundant than copper, which makes it a more affordable option for various applications. Additionally, aluminum coils require less maintenance and have a longer lifespan, reducing overall costs in the long run.

- Q: What are the different finishes available for aluminum coils?

- There are several different finishes available for aluminum coils, including mill finish, anodized finish, painted finish, and embossed finish. Mill finish is the standard finish and has a smooth, shiny appearance. Anodized finish involves an electrolytic process that adds a protective layer to the aluminum, providing increased durability and resistance to corrosion. Painted finish involves applying a coating of paint to the aluminum, offering a wide range of color options and enhanced aesthetics. Lastly, embossed finish involves creating patterns or textures on the aluminum surface, adding visual interest and improving grip.

Send your message to us

6061 Aluminum Coils for Sale - 1200 Aluminum Alloy Coil H112 Temper

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords