55Cr3 Alloy Flat Spring Steel Bars for Leaf Springs

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

55Cr3 Alloy Flat Spring Steel Bars for Leaf Springs

Product Information:

Certificate:ISO 9001:2008

International Standard:GB DIN JIS AISI ASTM SAE

Angle:Right-Angle & Double Angle

Technique:Oil Heat Treatment & Hot Rolled

Surface:Grooved / Plain-Smoothed

Quenchant:Oil /Water

Quenching Temperature:800°C~1000°C

Stressing Temperature:480°C~560°C

Raw Material;Concast Steel Billets (150×150mm)

OEM:Material Composition Offered By Customers

Allpication:Automotive suspension leaf springs

Rotary tools and Blades

Product Overviews:

| Product Name | Typical Grades | Diameter(mm) | Standard adopted |

| Carbon Steel | 20 (1020/S20C/C22) | Ø16-Ø300 | GB/SAE/JIS/DIN |

| 40 (1040/S40C/C40) | |||

| 45 (1045/S45C/C45) | |||

| Bearing Steel | GCr9 (51100/SUJ1) | Ø12-Ø250 | |

| GCr15 (52100/SUJ2/100Gr6) | |||

| GCr9SiMn (A485-Gr.1/SUJ3) | |||

| Cr-Mo Steel | 20Cr (5120/SCr420H/20Cr4) | Ø12-Ø250 | |

| 40Cr (5140/SCr440/41Cr4) | |||

| 42CrMo(4140/SCM440/42CrMo4) | |||

| Gear Steel | 20CrNiMo | Ø16-Ø600 | |

| 20CrMn(5115/SMnC420/20MnCr5) | |||

| 20CrNiMo(8620/SNCM220/20CrMiMo2) |

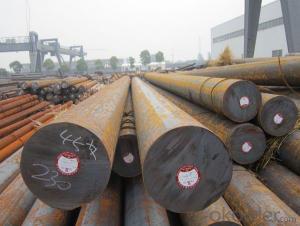

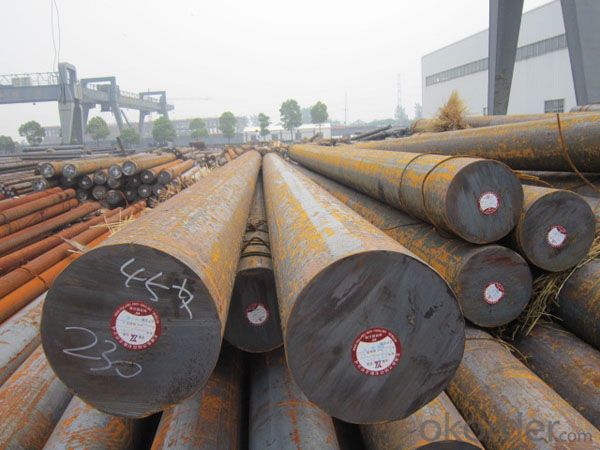

Product Show:

Our Advantages:

· Industry experience over 20 years.

· Shipment of goods -More than 70 countries worldwide.

· The most convenient transport and prompt delivery.

· Competitive price with best service.

· High technical production line with top quality products.

· High reputation based on best quality products.

With our experienced, enthusiastic and dynamic staffs, we assure to bring you the products with best quality, reasonable prices and good after-sales services under the motto: Friends First, Business After.

Communication, Experience, Expertise and Best efforts are our Promises to you.

- Q: What is the impact of titanium in special steel alloys?

- Special steel alloys greatly benefit from the inclusion of titanium, a remarkably versatile and valuable element. The addition of titanium to these alloys has a profound effect on their properties and performance. One of titanium's major impacts on special steel alloys is the enhancement of strength and durability. Titanium possesses a remarkable strength-to-weight ratio, meaning that even a small amount of titanium can significantly increase the strength of the steel alloy. This quality proves particularly advantageous in industries such as aerospace or automotive, where high strength and resistance to deformation or fatigue are essential. Moreover, titanium also contributes to the corrosion resistance of steel alloys. It forms a protective oxide layer on the steel's surface, effectively preventing or minimizing the detrimental effects of corrosion caused by exposure to various environmental factors like moisture, chemicals, or saltwater. This corrosion resistance becomes especially crucial in industries where steel is subjected to harsh conditions, such as marine or offshore applications. Another noteworthy impact of titanium in special steel alloys is its ability to enhance heat resistance. Titanium boasts a high melting point and exceptional thermal stability, making steel alloys containing titanium suitable for high-temperature applications. This characteristic holds particular significance in industries like power generation, where steel components must withstand extreme temperatures without compromising their structural integrity. Furthermore, titanium greatly improves the weldability of steel alloys. Acting as a deoxidizer, it reduces the presence of impurities and enhances the quality of welds. This attribute proves highly advantageous in manufacturing processes involving welding, as it guarantees strong and reliable joints. In summary, the influence of titanium on special steel alloys is multifaceted and highly advantageous. It bolsters the strength, durability, and corrosion resistance of steel, while simultaneously improving its heat resistance and weldability. These properties render titanium an invaluable element in the production of high-performance steel alloys for a wide array of industries.

- Q: How does wear-resistant steel protect against abrasive wear?

- Wear-resistant steel protects against abrasive wear by having a high hardness and toughness, which enables it to withstand the constant rubbing and grinding action of abrasive materials. The steel's resistance to deformation and ability to retain its shape under pressure prevent the abrasive particles from causing significant damage, thereby extending the lifespan of the material.

- Q: Can special steel be used in the mining industry?

- Yes, special steel can be used in the mining industry. Special steel, such as high-strength and wear-resistant steels, can be utilized for various applications in the mining industry, including the manufacturing of heavy machinery, equipment, and tools used in mining operations. These steels offer superior durability, strength, and resistance to abrasion, making them suitable for the harsh and demanding conditions present in mining environments.

- Q: How does the addition of nickel enhance the properties of special steel?

- The addition of nickel enhances the properties of special steel by improving its strength, toughness, and corrosion resistance. Nickel forms a solid solution with iron, which increases the overall strength and hardness of the steel. It also enhances the toughness, making it more resistant to cracking and fractures. Additionally, nickel improves the corrosion resistance of special steel, making it suitable for applications in aggressive environments or industries such as marine, chemical, and oil and gas.

- Q: How is special steel used in the production of cutting tools?

- Special steel is used in the production of cutting tools due to its unique properties that enhance the tool's performance. The high strength and durability of special steel allow cutting tools to withstand high temperatures and pressures, ensuring a longer lifespan. Additionally, special steel's excellent hardness and wear resistance enable cutting tools to maintain sharpness and precision, resulting in efficient and precise cutting operations.

- Q: How is the quality of special steel ensured?

- The quality of special steel is ensured through a combination of rigorous testing, strict quality control measures, and adherence to international standards and specifications. Special steel producers employ various methods such as chemical analysis, mechanical testing, and non-destructive testing to verify the composition, strength, and integrity of the steel. Additionally, special steel manufacturers often have dedicated quality assurance teams that closely monitor the production process to identify any potential issues and ensure the final product meets the required specifications.

- Q: What are the different construction grades of special steel?

- In various industries and applications, special steel with different construction grades is utilized. These grades are specifically engineered to offer superior strength, durability, and resistance to corrosion and other environmental factors. Some well-known construction grades of special steel include: 1. Mild Steel: This grade is widely used in construction and is considered the most basic. It has a low carbon content, making it easy to work with and weld. Mild steel is suitable for applications that require moderate strength and durability. 2. High-Strength Low-Alloy (HSLA) Steel: HSLA steel is a type of special steel that contains small amounts of alloying elements like copper, nickel, and vanadium. This grade provides higher strength and improved formability compared to mild steel. It is commonly used in structural applications where a higher strength-to-weight ratio is needed. 3. Weathering Steel: Also referred to as Cor-Ten steel, weathering steel is a special grade that develops a protective layer of rust when exposed to the elements. This layer acts as a barrier against further corrosion, making it ideal for outdoor structures. Weathering steel is commonly used in bridges, buildings, and other architectural applications. 4. Stainless Steel: Stainless steel is a corrosion-resistant alloy that contains at least 10.5% chromium. It offers exceptional resistance to corrosion, heat, and chemicals, making it suitable for a wide range of construction applications. Stainless steel is commonly used in building facades, roofing, and structural components. 5. Tool Steel: Tool steel is a special grade specifically designed for manufacturing tools, dies, and molds. It possesses high hardness, wear resistance, and toughness properties, making it suitable for applications that involve cutting, shaping, and forming materials. 6. Alloy Steel: Alloy steel is a special grade that incorporates additional alloying elements like manganese, silicon, nickel, and chromium. This grade provides enhanced strength, toughness, and wear resistance compared to carbon steel. Alloy steel finds common usage in machinery, equipment, and components subjected to high stress and wear. These examples highlight the various construction grades of special steel. Each grade possesses unique properties and is chosen based on the specific requirements of the application.

- Q: Can special steel be used in the aerospace parts manufacturing industry?

- Yes, special steel can be used in the aerospace parts manufacturing industry. Special steel alloys are often chosen for their superior strength, corrosion resistance, and high-temperature performance, making them ideal for aerospace applications where durability and reliability are crucial.

- Q: How do alloying elements affect the properties of special steel?

- Alloying elements play a crucial role in determining the properties of special steel. By adding specific elements to the steel composition, various desirable characteristics can be achieved. Firstly, alloying elements can improve the strength and hardness of the steel. For example, elements like chromium, nickel, and molybdenum enhance the steel's resistance to deformation and improve its overall toughness. This is particularly important in applications where the steel needs to withstand high temperatures, pressure, or mechanical stress. Moreover, alloying elements can enhance the corrosion resistance of special steel. Elements such as chromium, nickel, and copper create a protective oxide layer on the surface of the steel, which prevents it from rusting or corroding. This is particularly important in industries such as marine, oil and gas, and chemical processing, where exposure to corrosive environments is common. Additionally, alloying elements can influence the steel's ability to be welded, machined, or heat treated. For instance, elements like manganese and silicon improve the weldability of steel, making it easier to join different components together. On the other hand, elements like vanadium and tungsten increase the steel's ability to retain its hardness even after being subjected to high temperatures, making it suitable for applications involving heat treatment. Furthermore, alloying elements can impact the steel's electrical and magnetic properties. Elements like nickel and cobalt can enhance the steel's magnetic properties, making it suitable for applications in electrical transformers or magnetic devices. Conversely, elements like aluminum and titanium can improve the steel's electrical conductivity, making it ideal for electrical wiring or conductive components. In summary, alloying elements have a significant impact on the properties of special steel. They can enhance its strength, hardness, corrosion resistance, weldability, heat treatability, electrical conductivity, and magnetic properties. By carefully selecting and controlling the alloying elements, manufacturers can tailor the steel's properties to meet the specific requirements of various industries and applications.

- Q: What are the different methods for shot peening special steel?

- There are several methods for shot peening special steel, including air blast peening, wheel blast peening, and centrifugal peening. Air blast peening involves directing a stream of shot particles onto the surface using compressed air, while wheel blast peening uses a rotating wheel to propel the shot particles. Centrifugal peening utilizes a spinning wheel to throw the shot particles onto the steel surface. Each method has its own advantages and is used based on the specific requirements of the steel and the desired outcome of the shot peening process.

Send your message to us

55Cr3 Alloy Flat Spring Steel Bars for Leaf Springs

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords