Spring Flat Steel 65Mn for laminated Leaf Spring

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Spring Flat Steel 65Mn for laminated Leaf Spring

Product Description:

Measurement | Thickness | Width |

6mm~35mm | 40mm~150mm | |

Edge(Cross Section) | round edge profile to DIN59145 | Square edge profile to DIN59146 |

Bundle Weight | Around 2.0 MT | |

Technique | Hot Rolled | |

Surface | Grooved | Plain-smoothed |

Quenchant | Oil/Water | |

Temper Stressing | 480°C-560°C | |

Quenching Temprature: | 800°C-1000°C | |

OEM | Material Composition Offered by Customers | |

Application | sup9/sup9a/sup10/55Cr3/50CrV4 | Automotive suspension springs |

sup7/9260/30CrMnB/27CrMnB | Rotary tools and Blades | |

Payment Term | 100% L/C at Sight. | 30% T/T Down Payment, Balance Against B/L Copy. |

Packing | In bundles. Each bundle packed with 2 steel strips and 3 steel wires. | |

Features of 65Mn Spring Steel:

Certificated by ISO9001:2008. Highly Acclaimed Manufacturer

By fostering team-work and trust, with a commitment to quality and deliver.

By reliable conditions and services to build outstanding relationship with our customers.

By continuously improving our technology, processes, products and services

Useage of 65Mn Spring Steel:

This product has characteristics of good metallurgical quality such as high purity and uniformity, good surface quality by strictly controlling surface defect and decarburization, good mechanical properties especially on elastic limit, strength limit and tensile ratio, as well as accurate shape and dimension.

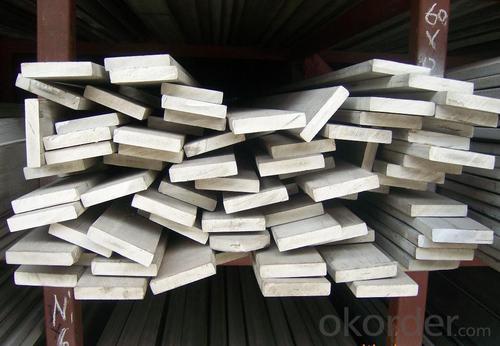

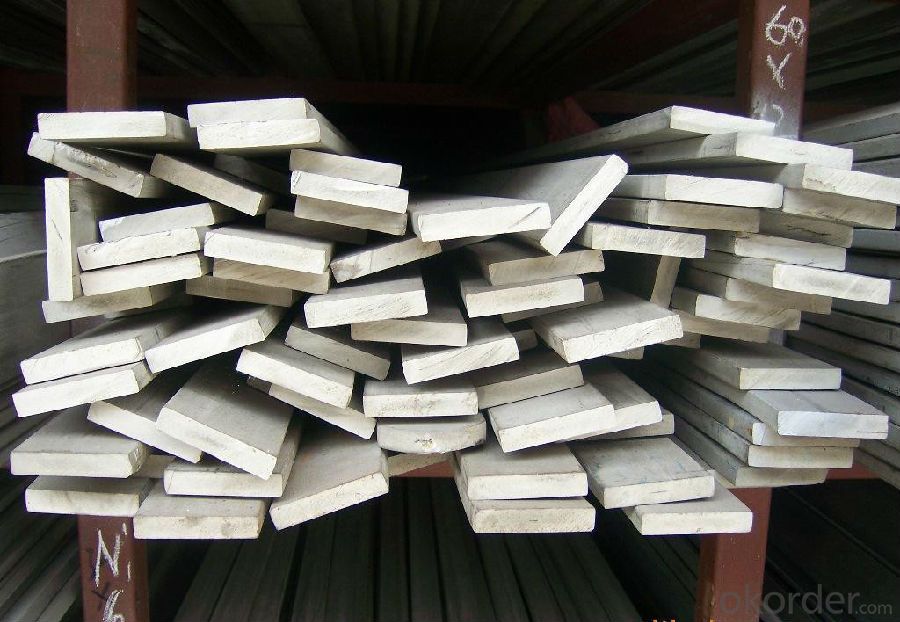

Product show:

- Q: What are the different surface hardening techniques for special steel?

- There are several surface hardening techniques for special steel, including carburizing, nitriding, induction hardening, flame hardening, and laser hardening.

- Q: How does special steel contribute to the renewable energy aftermarket industry?

- Special steel plays a crucial role in the renewable energy aftermarket industry by enhancing the efficiency, durability, and cost-effectiveness of renewable energy systems. One of the primary applications of special steel in this industry is in the manufacturing of wind turbine components. Wind turbines require high-strength and corrosion-resistant materials to withstand the harsh environmental conditions and generate electricity efficiently. Special steel alloys, such as high-strength low-alloy (HSLA) steel and stainless steel, offer superior mechanical properties, fatigue resistance, and excellent corrosion resistance, making them ideal for wind turbine tower structures, rotor blades, and other critical components. By using special steel in wind turbine manufacturing, the renewable energy aftermarket industry can benefit from increased turbine lifespan, reduced maintenance costs, and improved energy output. The strength and durability of special steel enable taller and larger wind turbine towers, allowing for the installation of turbines in areas with lower wind speeds. This expansion of suitable locations helps to maximize the energy production potential, making wind energy a more viable and widespread renewable energy source. Furthermore, special steel also contributes to the renewable energy aftermarket industry through its application in solar power systems. Solar panels require robust mounting structures to support the weight of the panels, withstand wind and snow loads, and ensure optimal sun exposure. Special steel, with its high strength-to-weight ratio and corrosion resistance, is commonly used in these mounting structures, providing long-lasting and reliable support for solar panels. In addition to wind and solar energy, special steel finds applications in other renewable energy systems such as hydroelectric power plants and geothermal systems. These industries benefit from the corrosion resistance and resistance to extreme temperatures offered by special steel, ensuring the longevity and efficiency of the equipment. Overall, special steel significantly contributes to the renewable energy aftermarket industry by enabling the production of reliable, durable, and efficient renewable energy systems. Through its use in wind turbines, solar panels, and other renewable energy technologies, special steel helps to enhance the performance and longevity of these systems, ultimately driving the growth and adoption of renewable energy sources worldwide.

- Q: What are the requirements for special steel used in high-pressure applications?

- The requirements for special steel used in high-pressure applications typically include high strength, excellent resistance to corrosion and oxidation, good weldability, and the ability to withstand extreme temperatures and pressures without deformation or failure. Additionally, the steel should have a high level of toughness to withstand impact and fatigue loads, as well as good dimensional stability to ensure proper sealing and performance in high-pressure environments.

- Q: How is special steel used in the production of automotive springs?

- Special steel is used in the production of automotive springs due to its unique properties that make it ideal for this application. Automotive springs, such as suspension springs and valve springs, need to be able to withstand heavy loads, repetitive stress, and high temperatures. Special steel, also known as alloy steel, is specifically designed to have enhanced mechanical properties compared to regular steel. It is typically made by adding additional alloying elements such as chromium, nickel, or molybdenum to improve its strength, hardness, and resistance to wear and fatigue. In the production of automotive springs, special steel is used to create springs that can handle the demanding conditions of the vehicle's suspension system. These springs must be able to absorb and distribute the weight of the vehicle, while also providing a smooth and comfortable ride. The high strength of special steel allows automotive springs to withstand heavy loads without deforming or breaking. This is crucial to ensure the stability and safety of the vehicle, especially during rough road conditions or when carrying heavy loads. Moreover, special steel's resistance to fatigue is essential in the production of automotive springs. These springs undergo millions of cycles of compression and expansion during the vehicle's lifetime. The fatigue resistance of special steel ensures that the springs can maintain their performance and reliability over an extended period. Additionally, special steel's resistance to wear and corrosion is beneficial in automotive applications. Springs are exposed to various environmental elements, such as moisture, dirt, and chemicals, which can lead to corrosion and degradation. Special steel's corrosion resistance helps to prolong the lifespan of automotive springs and maintain their functionality. In summary, the use of special steel in the production of automotive springs ensures that these critical components can withstand heavy loads, repetitive stress, and high temperatures. Its enhanced mechanical properties, including strength, fatigue resistance, and corrosion resistance, make it an ideal material choice for automotive springs, contributing to the overall performance and durability of vehicles.

- Q: How is maraging steel used in the production of rocket and missile components?

- Maraging steel is commonly used in the production of rocket and missile components due to its exceptional strength, toughness, and resistance to corrosion. Its unique properties allow for the creation of lightweight yet highly durable parts, such as rocket nozzles, casings, and guidance systems. Additionally, maraging steel can withstand extreme temperatures and pressures, making it suitable for the demanding conditions of space and military applications.

- Q: How does special steel perform in high-speed applications?

- Special steel is specifically designed to perform exceptionally well in high-speed applications. Its unique composition and manufacturing process make it highly resistant to heat, wear, and fatigue, allowing it to withstand the extreme conditions often encountered in high-speed operations. One of the key properties of special steel that makes it ideal for high-speed applications is its high strength-to-weight ratio. This means that it can maintain its structural integrity and withstand heavy loads while being lightweight, enabling it to efficiently handle the demands of high-speed operations. Additionally, special steel possesses excellent heat resistance, which is crucial in high-speed applications where temperatures can rise significantly. It has a high melting point and can maintain its strength and hardness even at elevated temperatures, preventing deformations or failures that could occur with other materials. Furthermore, special steel's exceptional wear resistance ensures long-lasting performance in high-speed applications. It is able to withstand the continuous friction and abrasive forces that occur at high speeds, reducing the need for frequent replacements and improving overall efficiency. Moreover, special steel's resistance to fatigue is another important factor in its performance in high-speed applications. It can withstand repetitive loading and cyclic stresses without developing cracks or fractures, ensuring a longer service life and minimizing the risk of sudden failures. In summary, special steel is specifically engineered to excel in high-speed applications. Its high strength-to-weight ratio, heat resistance, wear resistance, and fatigue resistance make it an ideal choice for industries such as aerospace, automotive, and manufacturing, where high-speed operations are common. Its superior performance in these applications ensures reliable and efficient performance, contributing to enhanced productivity and safety.

- Q: How does special steel contribute to the manufacturing of gears?

- Special steel plays a crucial role in the manufacturing of gears as it offers exceptional strength, durability, and wear resistance properties. The use of special steel allows gears to withstand heavy loads, high temperatures, and intense friction, ensuring their longevity and reliable performance. Moreover, the precise metallurgical properties of special steel enable gears to maintain their shape and dimensions accurately, resulting in smooth and efficient power transmission in various industries, including automotive, aerospace, and machinery.

- Q: How does special steel contribute to improving product efficiency in energy-intensive processes?

- Special steel plays a crucial role in enhancing product efficiency in energy-intensive processes by offering superior strength, durability, and heat resistance. It allows for the design and construction of lighter, more compact equipment, reducing energy consumption and improving overall efficiency. Additionally, special steel's corrosion resistance properties help extend the lifespan of machinery, minimizing downtime and maintenance costs. Its use in energy-intensive processes enables better performance, optimized resource utilization, and ultimately contributes to a greener and more sustainable industrial landscape.

- Q: Can special steel be used in the agricultural industry?

- Yes, special steel can be used in the agricultural industry. It is often utilized in the manufacturing of various farm equipment and machinery, such as plows, harrows, cultivators, and tractor components. Special steel's high strength, durability, and resistance to corrosion make it suitable for withstanding the demanding conditions and prolonged use in agricultural operations.

- Q: Can special steel be used in the agricultural sector?

- Yes, special steel can be used in the agricultural sector. Special steel, such as high-strength steel or corrosion-resistant steel, can be utilized in various applications within agriculture, including the manufacturing of farm equipment, machinery, tools, and infrastructure. These steel types offer enhanced durability, strength, and resistance to harsh environmental conditions, making them suitable for agricultural operations and ensuring long-lasting and efficient performance in the field.

Send your message to us

Spring Flat Steel 65Mn for laminated Leaf Spring

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords