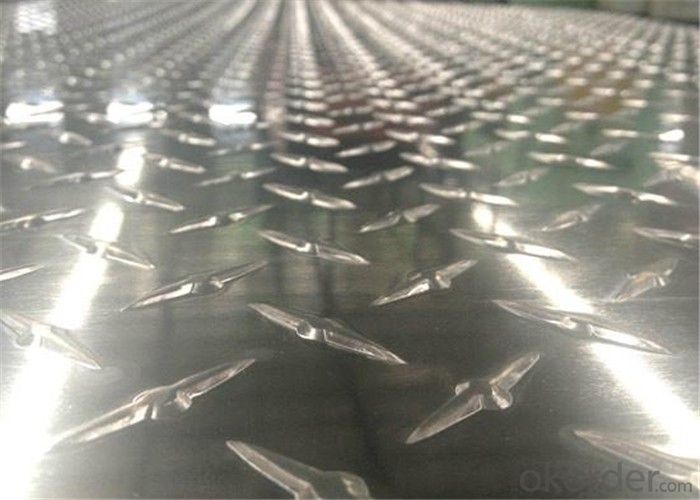

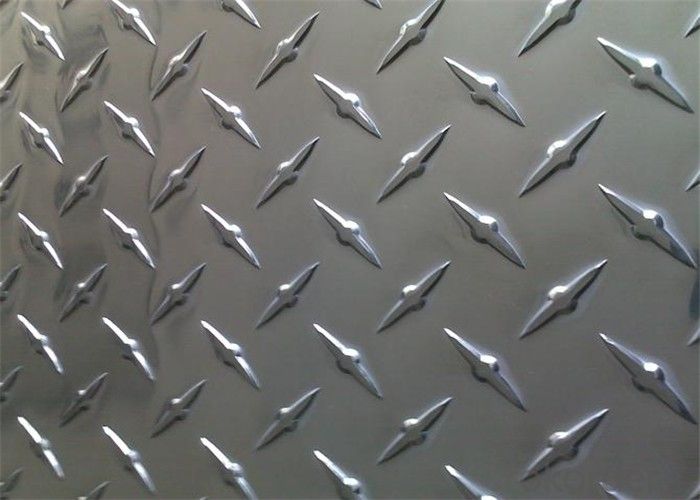

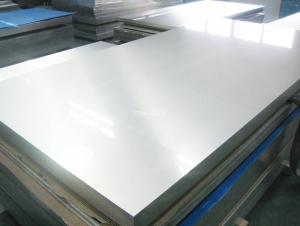

4 X 8 Aluminum Sheets - Pattern Aluminum Embossed Sheet and Coil Aluminium Plates

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

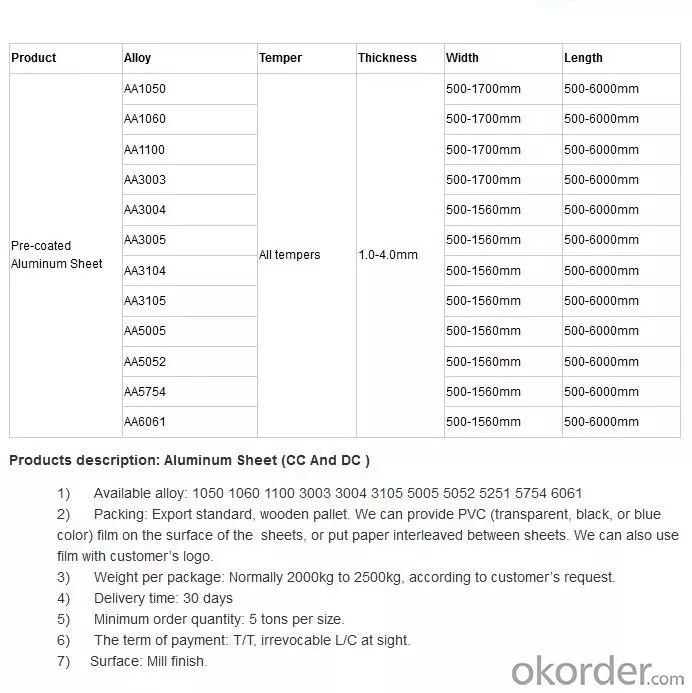

01) Alloy: A1050, A1060, A1070, A1100, A3003, A3105 etc

02) Aluminum thickness: 0.25mm~2.0mm

03) Aluminum standard width: 1200mm Max width: 1500mm

The embossed oxidized panel is beautiful, with thickness from 0.25mm to 2.0mm, while the maximum width is 1250mm, after pattern embossed, the thickness could be 0.25 to 2.0mm more. Additionally, we offer processing service for anozdizing aluminum sheet, which could further strength sheet’s ability of anti-corrosion.

Why we choose Okorder.com?

Okorder.com is a professional and reliable online E-market place

Providing a variety of products with reasonable prices

High quality goods provided by factory suppliers

Shipping to over 200 countries.

One-stop sourcing

Dubai Logistic Complex

Okorder Quality Control?

We hold a very strict quality control system to check every connector of our products for your safety.

Okorder services for you

1.7*24 hours Hotline & Email Service

2. Your inquiry related to our products or prices will be replied in 24hrs.

3. Well-trained and experienced staffs to answer all your enquires in fluent English

4. OEM&ODM, any your customized demand we can help you to design and put into product.

5. Distributor ship are offered for your unique design and some our current models

- Q: Explain the distinctions between aluminum sheets and aluminum foil in terms of thickness, uses, and properties.

- <p>Aluminum sheets and aluminum foil are both made from aluminum but differ in thickness and applications. Aluminum sheets are thicker and more rigid, typically used for construction, manufacturing, and as a packaging material. They offer better strength and durability. Aluminum foil, on the other hand, is very thin and flexible, commonly used for food packaging, cooking, and insulation. It's lightweight and has excellent heat and light reflection properties. Aluminum sheets are often anodized or coated for additional properties, while foil is valued for its purity and malleability.</p>

- Q: What is the tensile strength of aluminum?

- The tensile strength of aluminum varies depending on the specific alloy and temper. Generally, aluminum has a tensile strength ranging from 70 to 700 MPa (megapascals).

- Q: I have been doing this science prac at school and I have received some strange results. I measured the density of this metal, which leads me to believe it is Aluminium. Also, its silvery appearance supports this. When I have attempted to react it with Hydrochloric Acid, Sulfuric Acid and the nitrates/chlorides of a few metals, I have received some odd results.Despite having a high reactivity, the only substance it has reacted with so far out of all of the above is Tin Chloride. Am I doing something wrong? Is it possible that it isn't aluminium and rather a similar metal such as zinc? Thanks in advance :)

- Aluminum is very reactive so what happens is that it has a coat aluminum oxide as soon as it comes in contact with oxygen the outer layer forms aluminum oxide Al2O3. That is why Aluminum does not rust. The Al203 coat protects it.

- Q: What are the different alloy compositions available for aluminum sheets?

- There are several alloy compositions available for aluminum sheets, each with its own unique properties and applications. Some common alloy compositions include: 1. 1100: This alloy is known for its excellent corrosion resistance and high thermal conductivity. It is often used in chemical equipment, heat exchangers, and food processing equipment. 2. 3003: This alloy has good formability, moderate strength, and excellent corrosion resistance. It is commonly used in packaging, tanks, and architectural applications. 3. 5052: This alloy is known for its high strength and good formability. It is often used in marine applications, as well as in aircraft and automotive parts. 4. 6061: This alloy has excellent strength, good formability, and high corrosion resistance. It is commonly used in structural applications, such as in bridges, buildings, and transportation equipment. 5. 7075: This alloy is known for its extremely high strength and good machinability. It is often used in aerospace applications, as well as in high-stress parts for the automotive and sporting goods industries. These are just a few examples of the many alloy compositions available for aluminum sheets. The choice of alloy will depend on the specific requirements of the application, such as strength, corrosion resistance, formability, and machinability.

- Q: What are the semi hard ones? What are the alloys? What are the anti rust ones, such as 3003505210606061, 7075?

- Three 3000 series aluminum representing 30033003 3A21. Also known as China's 3000 series aluminum antirust aluminum production process is more outstanding.3000 series aluminum is made of manganese as main components. The contents of 1.0-1.5 in between. Is a series of anti rust function better. Routine application in air conditioning, ice box, car etc. in the moist environment, price more than 1000 series, is a commonly used alloy series.Four 4000 series aluminum on behalf of the 4A01 4000 series aluminum plate belongs to the high silicon content series. Usually silicon content between 4.5-6.0%. Belongs to the building material, mechanical parts, forging materials, welding materials; low melting point, good corrosion resistance of the product description: has the characteristics of heat resistance, wear resistanceFive series of 5000 representative 5052.5005.5083.5A05.5000 series is a commonly used aluminum alloy aluminum series, the main elements of magnesium, magnesium content in 3-5%. Also called aluminum magnesium alloy. The main characteristics of low density, high tensile strength, elongation rate is high. In the same area under the weight of the aluminium magnesium alloy is lower than that of the other series. It is commonly used in aviation, such as aircraft fuel tank. The application in the conventional industries are more widely. The processing technology for slab continuous casting and rolling, which belongs to the aluminum plate series so can do deep processing of aluminum oxidation. More mature system in our country in 5000 series aluminum one.Six series of 6000 representatives of 6061 mainly contains two elements of magnesium and silicon, so the advantages of 4000 series and 5000 Series 6061 is a cold forging processing of aluminum products, suitable for applications in corrosion resistance, oxidation resistance requirement. Use good interface features excellent, easy coating, processing is good. Can be used for low pressure weapons and aircraft joints.

- Q: What are the standard tolerances for aluminum sheets?

- The tolerances for aluminum sheets differ based on the specific industry and application. However, there are commonly accepted tolerances for aluminum sheets, such as thickness tolerances, flatness tolerances, and width and length tolerances. Thickness tolerances pertain to the allowable variation in the thickness of an aluminum sheet. The range of these tolerances depends on the grade and thickness of the sheet, and can be from +/- 0.005 inches to +/- 0.010 inches. Flatness tolerances specify the acceptable degree of flatness or deviation from a perfectly flat surface for an aluminum sheet. The range of flatness tolerances varies according to the application's specific requirements, and can be from a few thousandths of an inch to a few hundredths of an inch. Width and length tolerances define the allowable variation in the dimensions of an aluminum sheet. These tolerances can be expressed as +/- inches or as a percentage of the sheet's width or length. Generally, width and length tolerances for aluminum sheets fall within the range of +/- 0.25 to +/- 0.50 inches. It is important to note that these standard tolerances are subject to change and may differ depending on the specific industry, customer requirements, and the manufacturer's capabilities. Therefore, it is advisable to consult the manufacturer or industry-specific standards to determine the exact tolerances for aluminum sheets in a particular application.

- Q: This question asks for a list of adhesive types that are suitable for bonding aluminum sheets. It is important to provide a variety of options to give a comprehensive answer.

- <p>There are several types of adhesives used for bonding aluminum sheets together, including epoxy resins, which offer strong adhesion and resistance to heat and chemicals; polyurethane adhesives, known for their flexibility and durability; acrylic adhesives, which provide good adhesion and are easy to use; cyanoacrylates or 'super glues,' which bond quickly and are great for small, precise applications; and silicone adhesives, which are excellent for high-temperature applications and offer flexibility. Each type has its own advantages and is chosen based on the specific requirements of the bonding task, such as strength, flexibility, and resistance to environmental factors.</p>

- Q: What is the bending radius of aluminum sheets?

- The bending radius of aluminum sheets depends on various factors such as the thickness of the sheet, the alloy of aluminum being used, and the type of bending process. Generally, aluminum sheets with a thickness of 1mm or less can be bent to a radius equal to the sheet thickness without cracking. For thicker aluminum sheets, the bending radius should be larger than the sheet thickness to avoid cracking or fracturing. As a general rule, the bending radius for aluminum sheets with a thickness between 1mm and 6mm should be at least 1.5 times the sheet thickness. For example, a 3mm thick aluminum sheet should have a minimum bending radius of 4.5mm. It is important to note that these guidelines are approximate and may vary depending on the specific alloy and temper of aluminum being used. Furthermore, different bending processes such as air bending, bottoming, or coining may require different bending radii. It is recommended to consult the manufacturer's specifications or seek professional advice for precise bending radius requirements for specific aluminum sheet applications.

- Q: This question asks for a list of various types of aluminum sheets that can be used for decorative purposes.

- <p>Aluminum sheets are popular for decorative purposes due to their durability and versatility. The main types include: 1) Embossed Aluminum Sheets, which feature a textured surface for a unique look; 2) Perforated Aluminum Sheets, with holes of various sizes for a distinctive pattern; 3) Mirror Finish Aluminum Sheets, offering a reflective, shiny appearance; 4) Anodized Aluminum Sheets, which have a protective oxide layer for enhanced color and durability; 5) Brushed Aluminum Sheets, with a satin-like finish; 6) Color Coated Aluminum Sheets, available in a wide range of colors; 7) Composite Aluminum Panels, which combine aluminum with other materials for added strength and design options. Each type offers specific aesthetic and functional benefits for various decorative applications.</p>

- Q: why does aluminum sheet not react with sulfuric acid nut react with hydrochloric acid?

- aluminum reacts with hydrochloric acid,generating aluminium chloride which can dissolve in water. but aluminum reacts with sulfuric acid, generating aluminum sulfate which can't dissolve in water and will generate aluminum sulfate, a layer of protective film, preventing aluminum from reacting with sulfuric acid, so there is no significant phenomena.

Send your message to us

4 X 8 Aluminum Sheets - Pattern Aluminum Embossed Sheet and Coil Aluminium Plates

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords