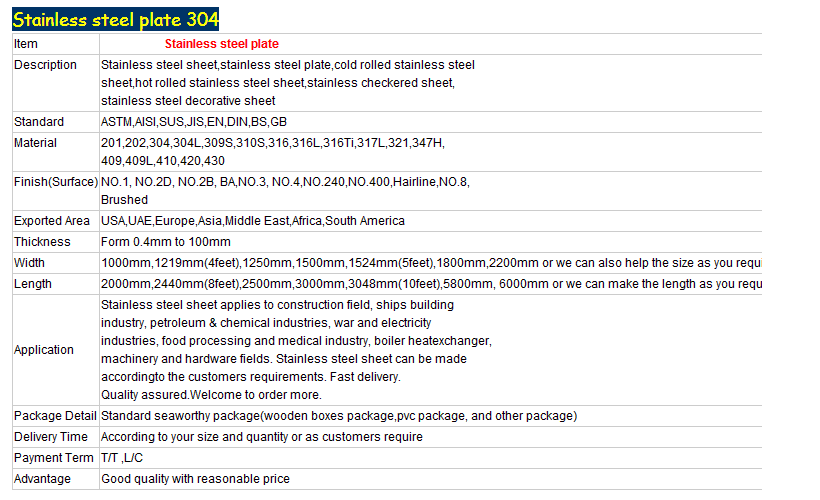

316 Made in china Tisco 304 stainless steel plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: Can stainless steel pipes be used for geothermal heating systems?

- Yes, stainless steel pipes can be used for geothermal heating systems. Stainless steel is a popular choice for geothermal applications due to its superior corrosion resistance properties. Geothermal heating systems involve the transfer of heat from the ground to the building, and stainless steel pipes are highly resistant to the corrosive effects of the soil and water found in geothermal environments. Additionally, stainless steel pipes can withstand high temperatures and pressure, making them suitable for the demanding conditions of geothermal systems. The durability and longevity of stainless steel pipes also make them a cost-effective choice for geothermal heating systems, as they require minimal maintenance and have a long lifespan.

- Q: How are stainless steel pipes different from galvanized pipes?

- Stainless steel pipes are different from galvanized pipes in terms of their composition and coating. Stainless steel pipes are made from an alloy of steel and chromium, which gives them excellent resistance to corrosion and rust. On the other hand, galvanized pipes are made from steel coated with a layer of zinc to protect against corrosion. While stainless steel pipes are more durable and long-lasting, galvanized pipes are more affordable and suitable for specific applications where corrosion resistance is not a primary concern.

- Q: Are stainless steel pipes suitable for pharmaceutical industries?

- Yes, stainless steel pipes are highly suitable for pharmaceutical industries. They offer excellent corrosion resistance, durability, and hygienic properties, making them ideal for transporting and storing pharmaceutical products. Stainless steel pipes are easy to clean, maintain, and sterilize, ensuring the integrity and safety of the pharmaceutical products being handled. Additionally, stainless steel is non-reactive, meaning it does not contaminate or affect the quality of the pharmaceutical substances being transported, making it a reliable choice for the pharmaceutical industry.

- Q: What is the difference between seamless and cold-rolled stainless steel pipes?

- The main difference between seamless and cold-rolled stainless steel pipes lies in their manufacturing process and the resulting characteristics. Seamless stainless steel pipes are produced by piercing a solid cylindrical billet of stainless steel and then processing it through various steps such as elongation and reduction to achieve the desired size and shape. This process ensures that the pipe has a smooth and even surface, without any welded seams. As a result, seamless stainless steel pipes exhibit superior strength, durability, and resistance to corrosion. They are also known for their ability to withstand high pressure and temperature conditions, making them suitable for a wide range of applications, including oil and gas pipelines, chemical processing, and power generation. On the other hand, cold-rolled stainless steel pipes are manufactured by rolling stainless steel sheets or strips at room temperature. This process involves passing the material through a series of rollers to reduce its thickness and shape it into a cylindrical form. Unlike seamless pipes, cold-rolled pipes have welded seams that may be visible on the surface. While these seams can potentially weaken the pipe, they can be mitigated by applying additional processes such as heat treatment or cold working to enhance the strength and integrity of the weld. The choice between seamless and cold-rolled stainless steel pipes depends on the specific requirements of the application. Seamless pipes are generally preferred when high strength, corrosion resistance, and pressure resistance are critical, especially in industries where leaks or failure can have severe consequences. Cold-rolled pipes, on the other hand, may be more suitable for applications where cost-effectiveness and moderate performance are sufficient, such as certain plumbing systems or decorative purposes. In summary, seamless stainless steel pipes are produced without welded seams, offering superior strength, durability, and resistance to corrosion, making them ideal for demanding applications. Cold-rolled stainless steel pipes, with visible welded seams, are generally more cost-effective and suitable for less demanding applications that don't require the same level of strength and corrosion resistance.

- Q: Are stainless steel pipes suitable for heat recovery systems?

- Stainless steel pipes, indeed, prove to be apt for heat recovery systems. With its exceptional durability and resistance against corrosion, stainless steel emerges as an ideal material for applications that involve extreme temperatures and harsh environments. The primary objective of heat recovery systems is to seize and exploit waste heat generated from industrial processes, and stainless steel pipes efficiently handle the heat transfer procedure while ensuring their steadfastness over time. Moreover, stainless steel showcases remarkable thermal conductivity, which further enables efficient heat transfer. Consequently, the utilization of stainless steel pipes in heat recovery systems guarantees utmost performance and longevity.

- Q: What is the difference between 347 and 321 stainless steel pipes?

- The main difference between 347 and 321 stainless steel pipes lies in their composition and intended use. 347 stainless steel contains a higher amount of niobium, which enhances its resistance to intergranular corrosion, making it suitable for high-temperature applications. On the other hand, 321 stainless steel has titanium as a stabilizing element, providing improved resistance against sensitization during welding.

- Q: What is the maximum length of a stainless steel pipe that can be manufactured?

- Practical limitations, including transportation and handling capabilities, typically dictate the maximum length achievable for stainless steel pipes. Generally, these pipes can vary in length from a few feet to several hundred feet. Nevertheless, the precise maximum length is subject to change based on factors like pipe diameter, thickness, and the manufacturing capabilities of the company or facility involved. To ascertain the specific maximum length of a stainless steel pipe, consultation with the manufacturer or supplier is crucial.

- Q: Can stainless steel pipes be cold worked?

- Yes, stainless steel pipes can be cold worked. Cold working is a process in which the metal is deformed at room temperature, typically through processes like bending, drawing, or rolling. Stainless steel's excellent mechanical properties and ductility make it well-suited for cold working, allowing for the creation of complex shapes and designs while retaining its strength and corrosion resistance.

- Q: What are the different grades of stainless steel pipes?

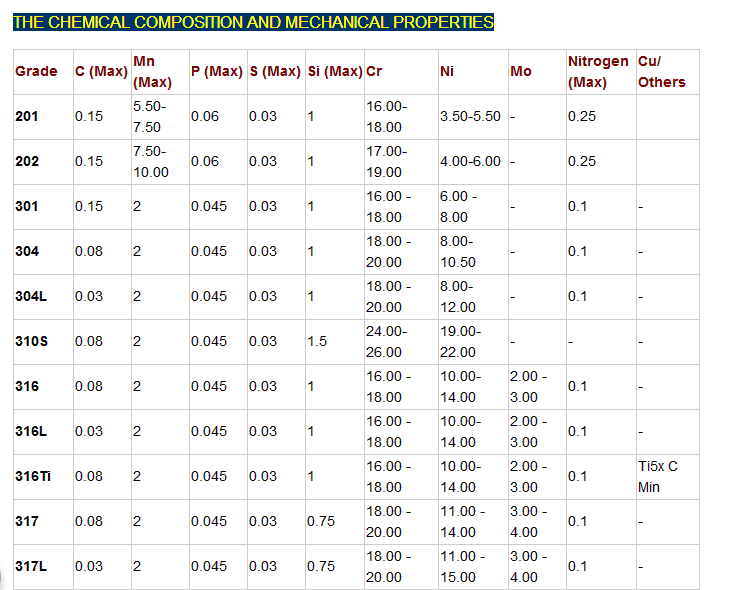

- There is a variety of stainless steel pipe grades available, each possessing its own distinct properties and applications. The most commonly utilized grades are as follows: 1. Grade 304: This stainless steel grade is widely employed in pipe manufacturing due to its exceptional corrosion resistance, heat resistance, and high strength. It is suitable for a diverse range of uses, including water pipes, food processing equipment, and architectural structures. 2. Grade 316: Renowned for its superior corrosion resistance, especially in environments with high chloride content, Grade 316 pipes are frequently utilized in marine applications, chemical processing plants, and medical equipment where protection against pitting and crevice corrosion is vital. 3. Grade 321: This grade is fortified with titanium, rendering it resistant to intergranular corrosion after exposure to elevated temperatures. Grade 321 pipes are commonly employed in applications involving high temperatures, such as exhaust systems, furnace components, and heat exchangers. 4. Grade 409: Specifically engineered for high-temperature applications like automotive exhaust systems, Grade 409 offers excellent heat resistance and a high degree of resistance to corrosion and oxidation. 5. Grade 904L: A highly alloyed austenitic stainless steel grade, Grade 904L displays exceptional resistance to a wide array of corrosive environments, including sulfuric acid, phosphoric acid, and chloride solutions. Grade 904L pipes are frequently used in chemical processing plants, the pulp and paper industry, and desalination plants. To ensure optimal performance and longevity, it is crucial to select the appropriate grade of stainless steel pipe based on the specific requirements of your application.

- Q: What kind of stainless steel square tube is used in ordinary square tubes?

- Stainless steel square tube is a kind of hollow long strip steel, because the section is square, so it is called square pipe. As the pipe conveying fluid, such as oil, gas, water, gas, steam, in addition, the bending and torsional strength of the same, the weight is light, so it is widely used in the manufacture of machinery parts and engineering structures.

Send your message to us

316 Made in china Tisco 304 stainless steel plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords