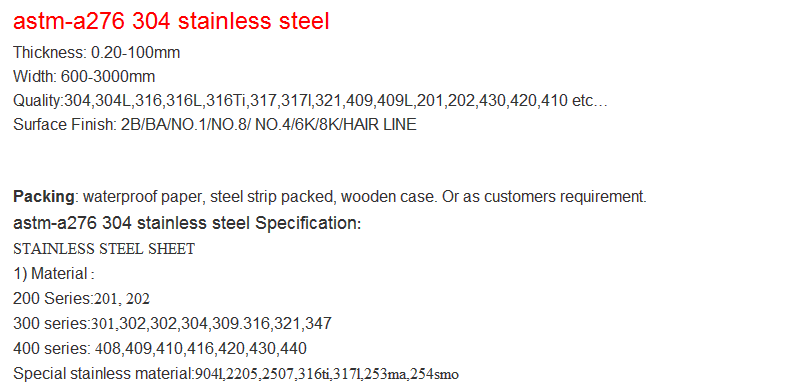

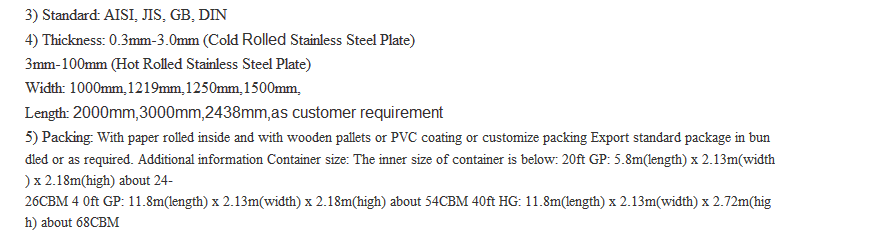

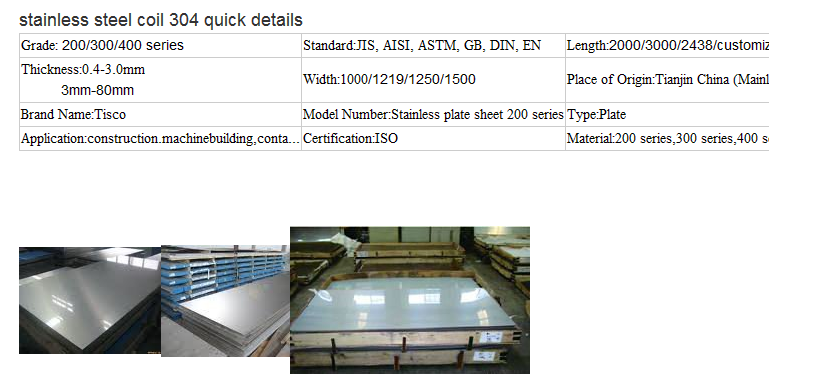

304 stainless steel,stainless steel sheet,stainless steel plate in china

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: Can stainless steel pipes be used for HVAC systems?

- Yes, stainless steel pipes can be used for HVAC systems. Stainless steel is a durable and corrosion-resistant material that is suitable for various applications, including HVAC systems. It offers excellent strength and reliability, making it an ideal choice for transporting fluids and gases in HVAC systems. Additionally, stainless steel pipes can withstand high temperatures and maintain their integrity, ensuring efficient and long-lasting performance in HVAC installations.

- Q: What are the different types of stainless steel pipe flanges?

- Various types of stainless steel pipe flanges are available to meet specific application needs and requirements. Some commonly used types include: 1. Weld Neck Flanges: These flanges have a tapered hub and are welded to the pipe, offering exceptional strength and durability. They are suitable for high-pressure and high-temperature applications. 2. Slip-On Flanges: These flanges slide onto the pipe and are then welded in place, providing a secure connection. They are easy to install and commonly used in low-pressure and non-critical applications. 3. Socket Weld Flanges: These flanges have a socket-like end that fits over the pipe and is then welded, ensuring leak resistance. They are used for smaller pipes. 4. Threaded Flanges: These flanges can be screwed onto the pipe due to their internal threads. They are easy to install and remove, making them suitable for low-pressure applications. 5. Lap Joint Flanges: These flanges consist of a stub end and a loose backing flange, allowing for frequent dismantling or precise alignment. 6. Blind Flanges: These solid flanges have no bore and are perfect for closing off the end of a pipe. They are commonly used in piping systems that require periodic inspection or cleaning. 7. Orifice Flanges: These flanges have concentric or eccentric holes to measure fluid flow rate. They find applications in flow measurement. 8. Spectacle Blind Flanges: These flanges combine a blind flange with a spacer and are used to separate pipe system sections. They can be easily removed for maintenance or repair. It is crucial to choose the appropriate stainless steel pipe flange type based on specific application requirements, including pressure, temperature, and fluid compatibility.

- Q: Are stainless steel pipes suitable for sewage treatment plants?

- Stainless steel pipes are indeed appropriate for sewage treatment plants. This is because stainless steel is an incredibly tough and corrosion-resistant material, which makes it well-suited for the harsh and corrosive conditions commonly found in sewage treatment plants. The material's superior resistance to corrosion prevents the pipes from deteriorating over time, ensuring a lengthier lifespan and reducing the necessity for frequent maintenance or replacements. Moreover, stainless steel pipes possess exceptional hygienic qualities, which are vital for sewage treatment plants to maintain proper sanitation. The smooth surface of these pipes prevents the accumulation of bacteria, biofilm, and other contaminants, making it easier to clean and sustain a high level of cleanliness. Additionally, stainless steel is environmentally friendly since it is entirely recyclable, thus contributing to sustainable practices in sewage treatment plants. In summary, stainless steel pipes are a dependable and suitable option for sewage treatment plants due to their durability, resistance to corrosion, hygienic properties, and eco-friendliness.

- Q: Can stainless steel pipes be used for vacuum systems?

- Yes, stainless steel pipes can be used for vacuum systems. Stainless steel is highly resistant to corrosion and has high strength, making it suitable for maintaining a vacuum environment without compromising its integrity.

- Q: How do you prevent backflow in stainless steel pipes?

- To prevent backflow in stainless steel pipes, there are a few key measures that can be taken. 1. Install a backflow preventer: This is a mechanical device that is installed in the pipe system to ensure that water flows in one direction and prevents any backflow. There are different types of backflow preventers available, such as check valves, double check valves, and reduced pressure zone devices. The selection of the appropriate backflow preventer depends on the specific requirements of the system and local codes and regulations. 2. Regular maintenance and inspection: It is important to regularly inspect the backflow preventer and ensure it is functioning properly. Any signs of wear or damage should be addressed immediately to prevent potential backflow issues. Regular maintenance can also include cleaning and replacing any worn-out parts to ensure optimal performance. 3. Pressure regulation: Maintaining proper pressure in the stainless steel pipes can also help prevent backflow. High pressure can cause water to flow in the opposite direction, leading to backflow. By installing pressure regulators or pressure-reducing valves, the water pressure can be controlled and maintained within the recommended range. 4. Air gaps: Incorporating air gaps in the system can provide an additional layer of protection against backflow. An air gap is a physical separation between the water source and the point of use, ensuring that there is no direct connection that could allow backflow to occur. 5. Adequate system design: Proper system design is crucial in preventing backflow. By ensuring that the stainless steel pipes have the correct sizing, appropriate slope, and proper connections, the risk of backflow can be minimized. Additionally, locating the backflow preventer in an easily accessible area can facilitate regular maintenance and inspection. By implementing these preventive measures, the risk of backflow in stainless steel pipes can be significantly reduced, promoting the safe and efficient flow of water in the system.

- Q: Can stainless steel pipes be used for underground installations?

- Yes, stainless steel pipes can be used for underground installations. Stainless steel is highly resistant to corrosion and can withstand harsh underground environments, making it a suitable choice for applications that require durability and longevity. Additionally, stainless steel pipes have excellent strength-to-weight ratio and are known for their high resistance to temperature variations, making them a reliable option for underground installations.

- Q: What is the difference between seamless and electric resistance welded stainless steel pipes?

- Seamless and electric resistance welded (ERW) stainless steel pipes vary in terms of their production process and the characteristics of the resulting pipes. Seamless stainless steel pipes are made through hot rolling or cold drawing. A solid cylindrical billet or ingot is heated and pierced to create a hollow tube. This tube is then elongated and reduced in diameter to achieve the desired size and thickness. Since seamless pipes lack any welding seam, they possess higher strength, corrosion resistance, and pressure resistance compared to welded pipes. They are commonly used in high-pressure applications due to their ability to withstand stress and resist leaks or failures. In contrast, electric resistance welded stainless steel pipes are manufactured by applying heat and pressure to longitudinally welded stainless steel strips or plates. The edges of the strip or plate are heated and fused together under pressure to form a tube. ERW pipes have a visible welded seam along their length due to the welding process. Although the welded seam may slightly diminish the overall strength and corrosion resistance of the pipe, ERW pipes are still highly durable and suitable for various applications. They are frequently utilized in industries such as oil and gas, petrochemical, and plumbing. To summarize, the primary distinction between seamless and electric resistance welded stainless steel pipes lies in their manufacturing process and the presence of a visible welded seam. Seamless pipes are produced without welding, resulting in superior strength and corrosion resistance, particularly in high-pressure applications. Conversely, ERW pipes are formed through welding, resulting in a visible seam, but they still possess good durability and are widely used in different industries.

- Q: Stainless steel pipe drilling?

- Acid resistant stainless steel is stainless steel, the resistance of air, steam, water and other weak corrosive medium or with stainless steel known as stainless steel; while the resistance to chemical corrosion (acid, alkali and salt chemical etching) corrosion of steel called acid resistant steel. Because of the difference in the chemical composition of the two, and make their corrosion resistance is different, ordinary stainless steel is generally not resistant to chemical medium corrosion, and acid resistant steel are generally stainless steel.

- Q: Are stainless steel pipes suitable for brewery fermentation tanks?

- Yes, stainless steel pipes are highly suitable for brewery fermentation tanks. Stainless steel is corrosion-resistant, easy to clean, and has excellent hygienic properties. It does not react with the beer, ensuring the quality and taste of the final product. Additionally, stainless steel pipes maintain temperature control and provide durability, making them a popular choice in the brewing industry.

- Q: Can stainless steel pipes be insulated with ceramic?

- Ceramic can indeed be used to insulate stainless steel pipes. It is commonly utilized in industrial settings that involve high temperatures. Ceramic insulation offers exceptional heat resistance and thermal insulation properties, making it an excellent choice. It can withstand extreme temperatures and effectively reduces heat transfer. Various industries utilize ceramic insulation to insulate pipes, tanks, furnaces, and other equipment. When applied to stainless steel pipes, ceramic insulation helps maintain the fluid's temperature, preventing heat loss or gain. Additionally, it provides protection against corrosion and mechanical damage. In summary, ceramic insulation is a suitable option for insulating stainless steel pipes in a wide range of applications.

Send your message to us

304 stainless steel,stainless steel sheet,stainless steel plate in china

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords