10 Foot By 10 Foot of 1mm 2mm Aluminum Sheet with Film Protection 1050 1100 3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

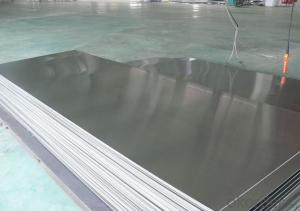

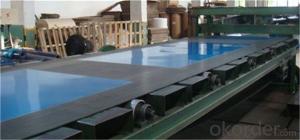

Aluminum Sheet for Making Aluminum Composite Panel

Aluminum sheet specifications:

1) Alloy : 1050 1060 1070 1100 2024 3003 3004 3105 3A21 5005 5052 5083 5754 5182 5454 5456 6061 6063 7075 8011 etc

2) Temper: O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc

3) Thickness: 0.1mm to 300mm

4) Width:20mm to 3300mm

5)Length: ≤ 12000mm

6) Protective film can be added

7) Production Line: DC and CC production line

Discription:

Width: 50-800mm

Thickness: 8-25mic

Length: 3-300m

Character:

High-temperature sterilization

Made of advanced food grade alu material,no pollution

Eco-friendly, recoverable and recyclable

Application:

widely used for food cooking, freezing wrapping, storing etc, the main application are for household and catering, which are targeting for retail market and food service market, such as hypermarket, chain store and hotel, restaurant etc.

Packing:

One roll in an individual box or printed PP bag

Certain quantities in a standard carton

Depends on customer’s request

Service

1. We have the good and professional team, have a good after-sales service.

2. Accept any drawings or your samples to develop new product.

3. Offer relateive technical support,quick response,all your inquire will replied within 24 hours.

4. OEM, buyer design, buyer label services provided.

5. Have the certification of ISO 9001, SGS.

6. Special discount and protection of sales area provided to our distributor.

FAQ

Q1:Do you provide sample? How many days will samples be finished?

Free samples will be provided if needed, but customers should undertake shipping cost or freight charges, samples will be finished in 5-7days

Q2: Can we visit your factory?

Welcome to our factory at any time.

Q3: Complaint solving process

Finding your salesman—Salesman provide you the solution (If it’s our responsibility, we will resend substitutes or return money or provide discount for your next order, etc.; If it’s shipping company’s responsibility, we will also help you until the problem is resolved.) —If salesman can’t solve your problem, please call our manager .

Q4: Delivery time

3~30working days after confirming the payment. If the order is urgent, we will push our workers to finish in advance.

Q5: What's your MOQ?

Normally 8MT are requested as the minium order quantity ,we shall give

additional instructions in special circumstances.

Q6: What are the terms of payment and currencies do you accept?

T/T or L/C is accepted, currently we appreciated your payment through

USD,EUR, RMB

Q7: Do you accept customized orders?

Yes, we do. Your customized orders are always welcomed. Please kindly offer us your samples or drawings, so that we can customize the products according to your preferences. About any further detail, please feel free to contact us.

Q8: What information should I let you know if I want to get a quotation?

Your detailed requirements regarding the products's dimensions, including shape, thickness, top out (length*width*height), and your order quantity are highly appreciated if you want further information about our quotation

Q9: How about the mass production?

The lead time of mass production depend on quantity, usually 25-30days (20FT) .

- Q: Can 101 aluminum sheets be used in the production of musical instruments?

- Yes, 101 aluminum sheets can be used in the production of musical instruments. Aluminum is a lightweight and durable metal that is commonly used in the manufacturing of various musical instruments. It offers good resonating properties and can produce a bright and clear sound. Additionally, aluminum is highly malleable, allowing it to be easily shaped and formed into different components of musical instruments such as bodies, frames, or keys. Therefore, 101 aluminum sheets can certainly be utilized in the production of musical instruments, contributing to their overall quality and performance.

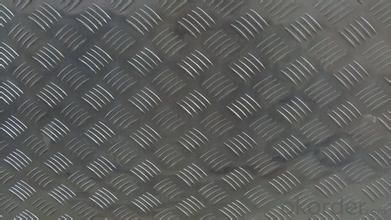

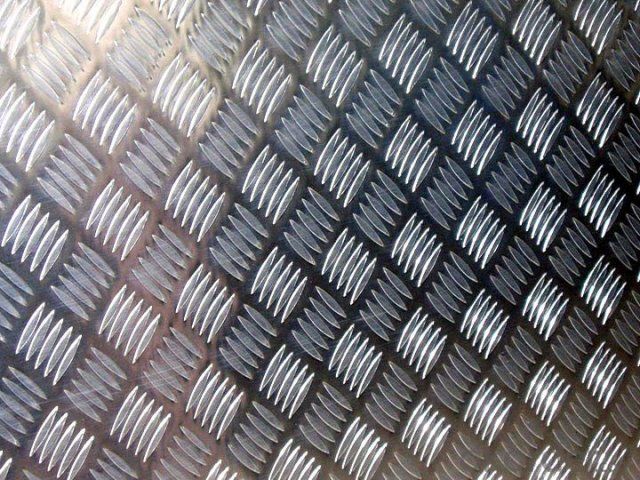

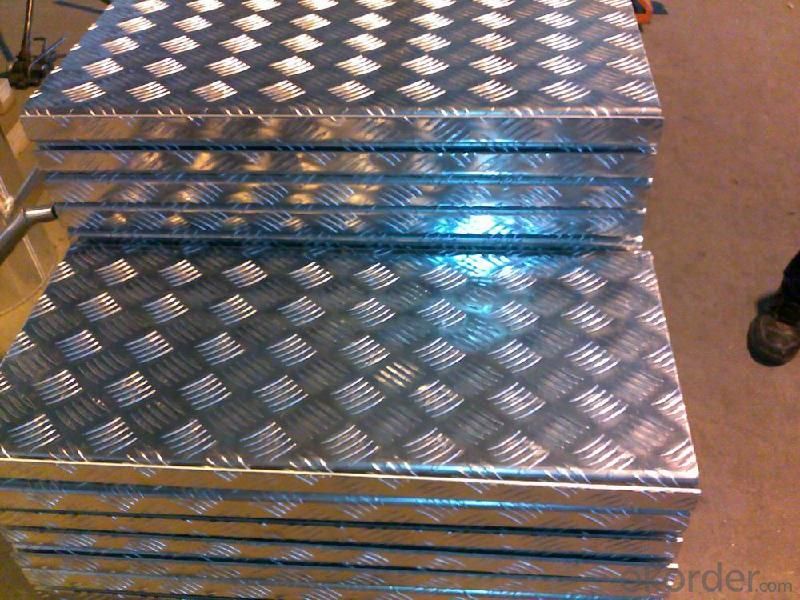

- Q: What kind of pattern aluminium plate has?

- Aluminum alloy decorative plate: Aluminum shallow pattern boardThe shallow pattern board of aluminum alloy is one of the excellent building decoration materials. It is exquisite pattern, color appearance, has the common advantages of ordinary aluminum plate, the stiffness is increased by 20%, anti fouling, anti scratch, anti abrasion ability has been improved, especially the increase of three-dimensional pattern and beautiful color, make the building more brightly.Aluminium alloy decorative panels: aluminium and aluminium alloy corrugated platesAluminum and Aluminum Alloy corrugated plate is widely used in the world of decorative materials, it is mainly used for wall decoration, can also be used for roofing, surface chemical treatment can have a variety of colors, good decorative effect, but also has a strong reflection of the light, very durable, the service life of up to 20 years. And it has a variety of colors, both decorative effect, but also has a strong ability to reflect sunlight. It can resist fire, moisture and corrosion.

- Q: What precautions should be taken to ensure safety while installing aluminum sheets?

- <p>When installing aluminum sheets, safety measures include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and hard hats. Ensure the work area is clear of debris and any tripping hazards. Use ladders and scaffolding that are in good condition and set up correctly. Always have a spotter when lifting heavy sheets and use proper lifting techniques to avoid back injuries. Keep hands and feet away from edges and corners to prevent cuts. Ensure all tools are in good working order and use them correctly. Follow all manufacturer's guidelines for installation and adhere to local safety regulations.</p>

- Q: This question asks for a list of various adhesive types that are suitable for bonding aluminum sheets together.

- <p>There are several types of adhesives used for bonding aluminum sheets, including epoxy adhesives, which are strong and resistant to heat and chemicals; acrylic adhesives, known for their flexibility and UV resistance; cyanoacrylate or super glue, which offers fast bonding; polyurethane adhesives, providing excellent adhesion and durability; and silicone adhesives, which are great for high-temperature applications. Each type has its specific properties and applications, making them suitable for different bonding requirements and environmental conditions.</p>

- Q: This question asks for a comparison between the benefits and drawbacks of utilizing products made from recycled aluminum.

- <p>Advantages of using recycled aluminum products include reduced energy consumption, lower greenhouse gas emissions, and a decrease in the need for raw material extraction. It also promotes waste reduction and supports a circular economy. Disadvantages might include potential quality concerns, as recycled aluminum might not always meet the same strength and durability standards as new aluminum. Additionally, there can be higher initial costs associated with recycling processes and the need for advanced sorting and processing technologies.</p>

- Q: This question asks about the effects of using aluminum sheets in the construction industry on the environment.

- <p>The environmental impacts of using aluminum sheets in construction are multifaceted. On the positive side, aluminum is lightweight, which reduces energy consumption during transportation. It is also recyclable, with a high percentage of construction aluminum being recycled, reducing waste. However, the production of aluminum is energy-intensive, contributing to greenhouse gas emissions. Additionally, mining for bauxite, the primary source of aluminum, can lead to habitat destruction and water pollution. Despite these concerns, aluminum's durability and resistance to corrosion can extend the lifespan of buildings, reducing the need for frequent replacements and thus the overall environmental footprint over time.</p>

- Q: Can aluminum sheet be used for roofing?

- Yes, aluminum sheet can be used for roofing. It is a popular choice for roofing due to its lightweight, durability, corrosion resistance, and ability to withstand harsh weather conditions.

- Q: Can aluminum sheets be used for outdoor furniture?

- Indeed, outdoor furniture can certainly make good use of aluminum sheets. Due to its durability, lightweight properties, and ability to resist rust and corrosion, aluminum is widely favored for outdoor furniture. It can endure diverse weather conditions, making it highly suitable for outdoor applications. Moreover, aluminum can be effortlessly molded and shaped into various designs, providing a vast array of furniture styles. By utilizing aluminum sheets in outdoor furniture, one ensures long-lasting quality and aesthetic charm, rendering it a pragmatic and adaptable option for outdoor settings.

- Q: What is the weight per square foot of 101 aluminum sheets?

- The weight per square foot of 101 aluminum sheets varies depending on the thickness of the sheets. Please provide the thickness of the aluminum sheets to determine the weight per square foot accurately.

- Q: Are aluminum sheets suitable for decorative screens?

- Yes, aluminum sheets are suitable for decorative screens. They are lightweight, durable, and can be easily customized into various shapes and designs. Additionally, aluminum's corrosion resistance makes it suitable for both indoor and outdoor applications, making it a popular choice for decorative screens.

Send your message to us

10 Foot By 10 Foot of 1mm 2mm Aluminum Sheet with Film Protection 1050 1100 3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords