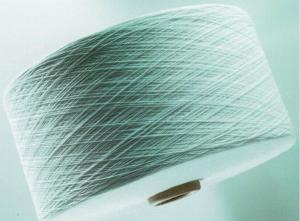

100% Viscose Yarn for Knitting and Weaving

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 MT m.t.

- Supply Capability:

- 100MT/Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification Of 100% Viscose Yarn For Knitting And Weaving From China

1 Yarn Count: NE30-NE50

2 Color: raw white

3 Material: 100% Viscose

4 Technics : Spin

5 Yarn Type: Spun

6 Package: usually pp bags packing , 25kgs per bag , 320 bags / one 20' container (8tons)

Features Of 100% Viscose Yarn For Knitting And Weaving From China

1 Well strength for knitting and weaving

2 Below 330 for knitting , above 380 for weaving

Application Of 100% Viscose Yarn For Knitting And Weaving From China

Anti-Bacteria, Anti-Pilling, Eco-Friendly, Moisture-Absorbent

Usage Of 100% Viscose Yarn For Knitting And Weaving From China

Sewing, Knitting, Hand Knitting, Weaving

Pictures Of 100% Viscose Yarn For Knitting And Weaving From China

- Q: Why in general the yarn in the woven fabric strength coefficient of use greater than 1

- (2) combed yarn: cotton yarn is combed by the spinning system spinning yarn. Combing yarn selection of high-quality raw materials, yarn in the fiber straight parallel, knot less, good gloss, dry, high strength, this type of cotton yarn used for weaving high-grade fabric

- Q: How does textile twist yarn identify?

- Therefore, in the detection of the composition of the textile, we can extract several from the fabric edge of the warp and weft, untwisted to form a loose as a sample, on the fire burning

- Q: What is Artex and Artex Products?

- According to statistics, Japan, the United States, Germany, Canada and so are the generous consumption of yarn products, but also China's exports of major markets

- Q: What is the difference between mesh cloth and Bali yarn?

- Balinese yarn, also known as glass yarn, English name voile, textile and apparel fabrics in a kind, is a plain weave woven thin transparent fabric, belonging to the woven fabric.

- Q: What is the diameter of a yarn of 40 yarns?

- (Inch): 1 ÷ {0.90 × [(Ne × 840) square)} = 1 ÷ {0.90 × [(40 × 840) square) = 0.006061608 inches

- Q: Men's sweaters with what yarn?

- The end of the proposed: the use of expanded cotton nitrile or other cotton blended yarn, yarn yarn price: 45-55 yuan / Kg or so, high-end: the proposed use of linen cotton or wool composition of the yarn, made of clothing look high fashion, The price will be relatively high.

- Q: What is the yarn?

- Yarn is a variety of textile fibers processed into a certain fineness of the product, used for weaving, rope, line, knitting and embroidery.

- Q: Forming Principle of Yarn of Textile Industry

- If you want to engage in it, you should use PLC or microcontroller to write programs, generally written in C language or ladder language.

- Q: Textile exports to South Korea need to do what certification, pure cotton yarn

- In the business sector and customs registration and other successful and import and export code.

- Q: Cotton yarn downstream enterprises have what kind of

- In particular, combed yarn can be used to produce high quality textile products, such as high-grade T-shirt, fine poplin, cotton yarn can also produce special industrial electric wax cloth, tire cord fabric, high-speed sewing thread and embroidery line.

1. Manufacturer Overview

| Location | Zhejiang,China |

| Year Established | 1997 |

| Annual Output Value | |

| Main Markets | North America, South America, Western Europe, eastern Europe, east Asia, central Asia, southeast Asia, the Middle East, Africa, Oceania |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

100% Viscose Yarn for Knitting and Weaving

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 MT m.t.

- Supply Capability:

- 100MT/Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords