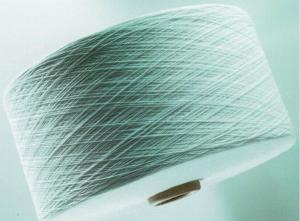

245D Air Textured Yarn ATY - Polyester Bright

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Product Type: | Other Yarn | Material: | 100%polyester | Yarn Type: | Spun,DTY,FDY,Filament,Texturized |

| Pattern: | Dyed | Technics: | Ring Spun | Feature: | Eco-Friendly,Anti-Pilling,Anti-Static,High Tenacity |

| Use: | Sewing,Knitting,Weaving,Embroidery | Twist: | as your request | Evenness: | average |

| Yarn Count: | 1500D,150D-3000D | Strength: | high | Place of Origin: | China (Mainland) |

| Brand Name: | Model Number: | KB-911 | yarn name: | air textured yarn | |

| color: | raw or dyed as your request | usage: | knitting,weaving,embroidery | MOQ: | 100-200Kg/color |

| lead Time: | 20 days after receivng the despoit | package: | as your request | payment: | L/C,T/T |

| Price Term: | FOB,CNF,CIF |

Packaging & Delivery

| Packaging Detail: | first class cartoon packing |

| Delivery Detail: | Within 20 to 30 days |

Specifications

Raw Air Textured Yarn

1.High quality

2.Reasonable price

3.Delivery on time

4.Quality Assurance

- Q: Textile waste silk (abandoned side yarn) what purpose ah?

- Traditional textile technology and equipment are complicated, rising production costs, to enable people to find new technologies

- Q: There are several kinds of yarn in textile mill

- 3. Fine yarn: fine yarn refers to 11 to 20 special (British 29 to 54 British branch) of the yarn. Such yarns are suitable for thin fabrics, such as fine cloth, poplin and the like. 4. Special fine yarn: special fine yarn refers to 10 special and below (British 58 British branch and above) of the yarn. This type of yarn for high-grade fine fabrics, such as high-shirt, worsted sweater and so on. According to spinning system points

- Q: How good is the textile economy?

- Unhealed tension of the yarn: As the distance between the cheese and the creel, the yarn is unwound due to the self-weight of the yarn and the friction force of the yarn when it is unwound. The high-speed operation produces the centrifugal force, The unwinding tension of the yarn.

- Q: What are the differences between the yarn and the yarn of the yarn?

- 3. Use Cotton yarn is widely used, it can be used as woven yarn, can also be used as knitting yarn, especially combed yarn can be used to produce high quality requirements of textiles, such as high-grade T-shirt, fine poplin, Can produce special industrial electric wax cloth, tire cord fabric, high-speed sewing thread and embroidery line.

- Q: What is the reason for the low strength of cotton yarn

- Feedback yarn sample feel, the middle part of the local strong is very low, there is no law. 36s yarn broken strong 9.6-10.9cn / tex, 40s yarn broken strength 8.2--10.4cn / tex.

- Q: How does the textile shake the knot?

- Right hand to find the yarn on the cheese head, the introduction of the upper guide bar, transferred to the left hand to introduce the lower guide bar and guide hook, and cut about 10 cm weak twist part.

- Q: What is the difference between mesh cloth and Bali yarn?

- Balinese yarn, also known as glass yarn, English name voile, textile and apparel fabrics in a kind, is a plain weave woven thin transparent fabric, belonging to the woven fabric.

- Q: What is the yarn?

- 1, the choice of neutral detergent for cleaning; 2, to avoid vigorously rubbing lead to clothing deformation or material damage;

- Q: What is the knitting yarn and the woven gauze?

- Knitted cloth needs a soft feel so the need for twist is relatively small and woven because the warp need to wear reed lift friction need a high strength so twist requirements are relatively large! In short the general fine gauze is a bridge-a-woven, mesh structure is knitted

- Q: Textile exports to South Korea need to do what certification, pure cotton yarn

- In the business sector and customs registration and other successful and import and export code.

Send your message to us

245D Air Textured Yarn ATY - Polyester Bright

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords