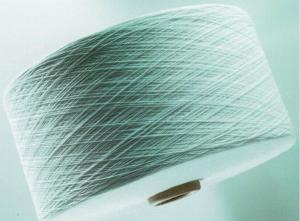

100% polyester filament air textured yarn (ATY) for knitting

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Product Type: | Other Yarn | Material: | 100%polyester | Yarn Type: | Filament |

| Pattern: | raw or dyed | Technics: | Ring Spun | Feature: | Eco-Friendly,Anti-Static,Recycled,High Tenacity |

| Use: | Sewing,Hand Knitting,Knitting,Weaving,Embroidery | Twist: | as your request | Evenness: | average |

| Yarn Count: | 1500D,150D-3000D | Strength: | high | Place of Origin: | China (Mainland) |

| Brand Name: | Model Number: | KB-701 | Price Term: | FOB,CNF,CIF | |

| payment:: | L/C,T/T | package: | as your request | lead Time: | Usully 20 days,specially order can discuss separately |

| length: | 500m, 1000m, 1500m or as your request | MOQ: | 100-200Kg/color | more feature: | Imitation linen |

| usage: | knitting,weaving(for curtain, sofa cloth, decorative cloth, etc.) | color: | raw or dyed as your request | yarn name: | 150D-3000D 100% polyester filament ATY for knitting |

Packaging & Delivery

| Packaging Detail: | first class cartoon packing |

| Delivery Detail: | Within 20 to 30 days |

Specifications

Polyester Air Textured Yarn

1)Export quality

2)Reasonable price

3)On time delivery

100% polyester filament air textured yarn (ATY) for knitting

aty:

Strongly technology support and serious produce manage, good quality control system! air jet textured polyester filament

aty :

We can supply you air jet textured polyester filament yam ranged from 100D-3000D and various color dope dyed. Pls check the detailed information about our produce:

Technical parameter:

(1) Breaking Strength: 2.3CN/DTEX

(2) Breaking Elongation: (20+/- 5) %

(3) Oil Content: no more 1.5%

(4) Boling Water Shrinkage: no more 7%

- Q: Why in general the yarn in the woven fabric strength coefficient of use greater than 1

- Cotton yarn is made of cotton fiber by spinning the yarn, processed by the stock after the cotton line. According to the different spinning process, can be divided into carded yarn and combed yarn. (1) carded yarn: cotton fiber is the ordinary spinning system spinning yarn

- Q: How does textile twist yarn identify?

- Observe the fiber near the flame, contact with the flame, leaving the flame produced by a variety of different phenomena and the combustion of the odor, the post-combustion residue to identify the fiber type.

- Q: Textile waste silk (abandoned side yarn) what purpose ah?

- Textile waste silk (discarded yarn) is a non-woven textile raw materials, usually re-opened, non-woven non-woven equipment production, should be 90% of the product is the production of non-woven fabrics. The reason for this is as follows

- Q: What is the reason why the textile yarns are yarn

- In the choice of the purchase of wool, you must buy enough volume, so as not to be off the goods and can not complete the situation. On the other hand, some sell well-selling varieties of wool, although no goods, but also have to keep the stickers on the wool ball, used for identification when outsourcing.

- Q: There are several yarns of textile mills

- This type of yarn for high-grade fine fabrics, such as high-shirt, worsted sweater and so on. According to the spinning system. Spinning yarn Worsted yarn, also known as combed yarn, refers to yarns that are spun by combing processes, including combed cotton yarns and combed yarns. The fibers are parallel to the fiber in a high degree of straightness, smooth, smooth, but higher cost, higher yarn count. Combed yarn is mainly used for high-grade fabrics and knitwear raw materials, such as fine spinning, gabardine it, tweed, sweater and so on.

- Q: How to choose the twist of the roving?

- Roving twist factor is too small, easy to produce accidental drawing, increase the broken, so that the product is not uniform.Therefore, the roving twist coefficient is the same as the drafting factor, roller pressure, roller gauge, etc. The roving twist factor is mainly based on The length of the fiber, the spinning varieties, the thickness of the roving, the post-spinning process and the temperature and humidity factors to choose to control:

- Q: What is the yarn inside the textile industry is what kind of yarn?

- Touch and see only the consumer's method, the textile industry is not by touch and it seems to distinguish the type of yarn, it is to use the test means.

- Q: What are the types of cotton yarns?

- (Also known as S twist) yarn, used to weave the weft of the weft yarn (2) according to twist to the point: ① backhand twist (also known as Z twist) yarn, in a variety of fabrics in the most widely used;

- Q: What are the types of textile yarns?

- (Polyester) Polypropylene (PP) Polyethylene (PE) Polyester (Polyester) Polyester (PPL) Polyethylene (PE)

- Q: From the yarn to the finished textile fabric production process

- Is the famous American chemist Carothers and his research team invented. The main varieties of nylon are nylon 6 and nylon 66, accounting for the absolute dominant, followed by nylon 11, nylon 12, nylon 610, nylon 612, in addition to nylon 1010, nylon 46, nylon 7, nylon 9, nylon 13, Varieties are nylon 6I, nylon 9T and special nylon MXD6 (barrier resin) and so on

Send your message to us

100% polyester filament air textured yarn (ATY) for knitting

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords