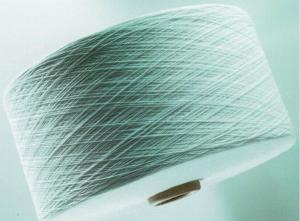

Colored Metallic Yarn With High Quality From China

- Loading Port:

- Ningbo Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 MT m.t.

- Supply Capability:

- 15MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification Of Colored Metallic Yarn With High Quality From China

1 Thickness : 12 micron, 23micron,30 micron,50micron

2 Color : Golden, Slivery,Green,Blue,Yellow etc.

3 Material : cutting aluminum-plated and dyed polyester films

4 Technics : Ring Spun

5 Style: M-Type

6 Package : net weight 300g/bobbin ,64bobbins/carton

19.2kilo/carton . one 20 GP can contain 545cartons = 10464 kg

Feature Of Colored Metallic Yarn With High Quality From China

High Tenacity, Anti-Pilling

Application Of Colored Metallic Yarn With High Quality From China

Sewing, Knitting, Weaving

Usuage Of Colored Metallic Yarn With High Quality From China

Sewing, Hand Knitting, Knitting, Weaving

Pictures Of Colored Metallic Yarn With High Quality From China

- Q: How much does it cost to do a small cotton textile mill?

- Also open a small spinning mill very tired, to know how the current workers are not obedient. Small factories, then generally have to sell intermediaries, one to own sales, two words will have the initiative to contact you.

- Q: What is the reason why the textile yarns are yarn

- Fine is the most widely used wool varieties, whether it is infants, children, women or men's clothing can be used for such rough wool weaving, weaving pattern fine and elegant.

- Q: What are the benefits of the steaming machine to the textile industry?

- (4) knitting process, the coil forming uniform; (5) the size of the finished product size and stability; (6) no additional humidification system; (7) to eliminate static electricity.

- Q: Textile yarn 75d ppt memory silk how much money meal?

- After dyeing, the surface will fold a lot of side pores, can quickly sweat and quickly dry, quickly sweat out.

- Q: Cotton cotton yarn consumption of cotton how much?

- Tons of yarn consumption of cotton "and the raw material grade and length and with the rate, equipment, technology, operation, and even with the spinning branch (Turks) and the workshop temperature and humidity are related to the amount of cotton consumption quota is as follows:

- Q: What is yarn support?

- Yarn count is the yarn count, divided into metric and imperial count.

- Q: Textile spinning mill management system

- The same for the financial, the need to be able to generate reports from time to time to understand the day, month, quarter, year of the report statistics, and for sales need to be able to grasp the customer's information and inventory, and further sales, production, procurement, etc. And so on a series of work processes.

- Q: From the yarn to the finished textile fabric production process

- Nylon modified varieties such as nylon, single-cast nylon (MC nylon), reactive injection molding (RIM) nylon, aromatic nylon, transparent nylon, high impact (super tough) nylon, electroplated nylon, conductive nylon , Flame retardant nylon, nylon and other polymer blends and alloys, to meet the different special requirements, widely used as metal, wood and other traditional materials substitutes, as a variety of structural materials.

- Q: Cotton yarn downstream enterprises have what kind of

- Suggest you can find, textile mills, weaving plants, silk factory, industrial cloth factory, sewing factory, etc.

- Q: How to reduce the cost of textile yarn dyeing

- First analyze your cost structure: Dyeing auxiliaries, labor (including management), water and electricity, equipment

1. Manufacturer Overview

| Location | Zhejiang,China |

| Year Established | 1997 |

| Annual Output Value | |

| Main Markets | North America, South America, Western Europe, eastern Europe, east Asia, central Asia, southeast Asia, the Middle East, Africa, Oceania |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Colored Metallic Yarn With High Quality From China

- Loading Port:

- Ningbo Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 MT m.t.

- Supply Capability:

- 15MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords