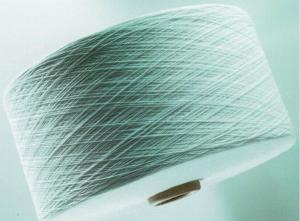

100% Polyester ATY

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Material: | 100% Polyester | Pattern: | Raw | Yarn Type: | Filament |

| Use: | Weaving | Twist: | non | Yarn Count: | 144F |

| Strength: | 2.5g/d | Place of Origin: | Brand Name: | ||

| Model Number: | TT17144 | Denier: | 170d±5 or customization | Elongation: | 40%±5 |

| O.P.U: | 1.5%±0.5 or customization . |

Packaging & Delivery

| Packaging Detail: | 3.5kg~4kg/roll, 6 rolls/carton |

| Delivery Detail: | Depending on the quantity of order |

Specifications

ATY - air textured filament for weaving

Cotton-like yarn

Good touching feeling

High quality

Competitive price

ATY - 100% Polyester air textured filament yarn

Product Description

| Product Details | |

| Material | 100% Polyester |

| Technics | Air Textured Yarn |

| Yarn Type | Filament |

| Luster | Semi-Dull Yarn, Full-Dull Yarn |

| Use | Weaving |

| Yarn Count | 90D~500D |

| Tenacity | 2.5g/d~3.5g/d |

| Pattern | RAW White |

Packaging & Shipping

| Packing & Delivery | |

| Packing | 3.5kg~4kg/roll, 6 rolls/carton |

| Delivery | Depending on the quantity of order |

- Q: What does JC40S cotton yarn mean?

- Cotton yarn is made of cotton fiber by spinning the yarn, processed by the stock after the cotton thread. According to the different spinning process, can be divided into carded yarn and combed yarn.

- Q: Why in general the yarn in the woven fabric strength coefficient of use greater than 1

- Introduction 1. Processing of cotton yarn manufacturing methods are more complex, in general, there are two kinds of spinning methods, that is, carded spinning and combing spinning. (1) carded spinning process: with cotton → open cotton → carding → parallel → roving → spun yarn → post-processing → finished product inspection. (2) combing spinning process: with cotton → open cotton → carding → strip → strip → combing → parallel → roving → spun yarn → post-processing → finished product inspection.

- Q: What is the process of towel in the textile?

- The above data should also be considered after the first dyeing or weaving after dyeing, but also consider whether there are other processing, such as cut velvet, embroidery, printing and so on.

- Q: There are several kinds of yarn in textile mill

- Usually, according to the yarn used in raw materials, yarn thickness, spinning method, spinning system, yarn structure and yarn use classification. According to the yarn raw material points 1. Pure spinning Pure spinning is a yarn made of a fiber material such as cotton yarn, wool yarn, hemp yarn and silk spinning. This type of yarn is suitable for making pure textile.

- Q: How much does it cost to do a small cotton textile mill?

- You are really interesting, it is estimated that you have not even into the spinning mill it! From the beginning of the cotton is the spinning mill is necessary! The front of the machine do not, unless you want to start from the cotton start

- Q: What is the reason why the textile yarns are yarn

- In the rough is the most commonly used knitting cold clothing, weaving the clothing is not too thick is not too thin. High thick is also the best wool weaving clothing.

- Q: Will the following kind of yarn which fine? A32 support, B21 support

- At a nominal moisture regain, a 1-pound (453, 5g) heavy yarn length of 840 yards (one yard equal to 0,9144 m) is a multiple of 1 pound, which is just 840 yards long, ; 1 pound yarn length of 21 × 840 yards long, the fineness of the yarn 21, written for 21s

- Q: What are the differences between the yarn and the yarn of the yarn?

- 2. Processing of cotton yarn manufacturing methods are more complex, in general, there are two kinds of spinning methods, that is, cotton spinning and combing spinning. (1) carding cotton spinning process: with cotton → open cotton → carding → → → → roving → yarn → post-processing → finished product inspection. (2) combing spinning process: with cotton → open cotton → carding → combing → parallel → roving → spun yarn → post-processing → finished product inspection.

- Q: What are the benefits of the steaming machine to the textile industry?

- Quick steaming box - treatment effect: 1. Relaxation, shaping, humidification. 2. Increase the yarn strength, reduce the fracture (cotton yarn breaking strength will increase by 10%, wool yarn elongation increased by 30%); Cotton yarn feathers fall by 30-45%; 4. Yarn moisture uniformity, control moisture regain high precision;

- Q: Men's sweaters with what yarn?

- Needles: autumn and winter clothing generally choose some of the needle, the proposed 3-9 pin, yarn count: according to the number of yarn count should also be: 7-20S more appropriate. Color: autumn and winter men's best choice in the dark, wild color for the black, sapphire blue, Zhang Qing and other dark.

Send your message to us

100% Polyester ATY

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches