10 Foot By 10 Foot of Aluminum Sheets 8xxx Hot Rolled

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Sheets 8xxx Hot Rolled Description

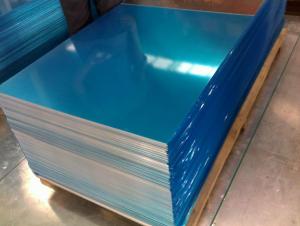

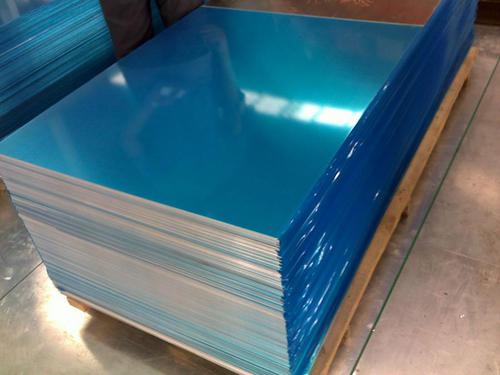

Aluminum Sheets 8xxx Hot Rolled is cut from aluminum coils 8xxx. Aluminum Sheets 8xxx Hot Rolled has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

Aluminum Sheets 8xxx Hot Rolled is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of Aluminum Sheets 8xxx Hot Rolled

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

3.Aluminum Sheets 8xxx Hot Rolled Images

4.Aluminum Sheets 8xxx Hot Rolled Specification

| Alloy | AA8xxx (AA8011,AA8006 etc.) |

| Temper | H14,H16,H18,H22,H24,H26,H32,O/F |

| Thickness | 0.2mm--100mm |

| Width | 30mm--1700mm |

| Standard | GB/T 3880-2006 |

5. FAQ of Aluminum Sheets 8xxx Hot Rolled

A.When will you deliver the products?

The Aluminum Sheets 8xxx Hot Rolled will be delivered within 35 days after receiving advanced payment or original L/C.

B.What is the MOQ?

The MOQ for each size is 7-8 tons.

- Q: Are the aluminum sheets suitable for manufacturing lighting fixtures?

- Aluminum sheets are a great option when it comes to making lighting fixtures. Aluminum is a material that is both lightweight and flexible, offering numerous advantages for the manufacturing process. One of the main advantages is its exceptional ability to conduct heat, which means it can effectively disperse any heat produced by the lighting components. This is beneficial as it helps to extend the lifespan of the fixtures and maintain their efficiency. Moreover, aluminum is resistant to corrosion, which is particularly important for lighting fixtures as they are often exposed to different environmental conditions. This quality ensures that the fixtures will not deteriorate over time and can withstand outdoor elements. Additionally, aluminum sheets are incredibly malleable, meaning they can be easily shaped and molded into various forms and sizes. This allows manufacturers to create lighting fixtures with customized designs, catering to both functional and aesthetic requirements. Furthermore, aluminum is a sustainable and environmentally friendly material. It is recyclable, which helps to reduce the environmental impact of the manufacturing process. This makes aluminum sheets a popular choice for manufacturers who prioritize sustainability in their operations. In conclusion, the exceptional thermal conductivity, corrosion resistance, versatility, and sustainability of aluminum sheets make them highly suitable for manufacturing lighting fixtures.

- Q: What are the different forms of aluminum sheet available?

- There are several different forms of aluminum sheet available, including plain, embossed, perforated, and painted aluminum sheets.

- Q: What is the bending radius for aluminum sheets?

- The bending radius for aluminum sheets varies depending on the thickness and grade of the aluminum. Generally, for thin aluminum sheets, the bending radius can be around 1.5 times the thickness of the sheet. However, for thicker sheets, the bending radius may need to be larger to avoid cracking or deformation. It is recommended to refer to specific bending charts or consult with a metal fabrication expert for precise bending radius guidelines for different aluminum sheets.

- Q: Explain the similarities and differences in the properties of aluminum metal, Al(s) and aluminum oxide (a salt) Al203(s) in terms of the particles and forces present.. thanks doods!

- Aluminum metal is not found in nature, only aluminum oxide is in the mine or ground and they have to separate it from the oxidation to make a useful metal.

- Q: Describe the steps involved in the production of aluminum sheets.

- <p>The process of manufacturing aluminum sheets involves several key steps. Initially, raw materials, primarily bauxite, are mined and then processed to extract alumina (aluminum oxide). This alumina is then mixed with cryolite and fed into a reduction cell where it is subjected to a strong electric current, causing the aluminum to be reduced and extracted. The molten aluminum is then poured into molds to cool and solidify into ingots. These ingots are subsequently rolled into sheets in a hot or cold rolling process, where they are gradually reduced in thickness and width. The sheets are then annealed to improve their ductility and strength. Finally, they undergo various finishing processes such as cleaning, coating, or cutting to meet specific requirements before being packaged and shipped to customers.</p>

- Q: How do you calculate the weight of an aluminum sheet?

- To calculate the weight of an aluminum sheet, you need to know the dimensions (length, width, and thickness) of the sheet and the density of aluminum. The weight can be calculated by multiplying these three values together and then multiplying it by the density of aluminum.

- Q: Is it possible to utilize aluminum sheets in the construction of environmentally friendly buildings?

- <p>Yes, aluminum sheets can be used for green building materials. They are lightweight, durable, and have high recyclability, which reduces waste. Aluminum is also energy-efficient in production and use, and its reflective properties can help in reducing heat absorption, thus lowering cooling costs. Additionally, aluminum's resistance to corrosion and weathering means it requires less maintenance, contributing to its sustainability in green building practices.</p>

- Q: Can aluminum sheets be used for electronic enclosures?

- Yes, aluminum sheets can be used for electronic enclosures. Aluminum is a lightweight and durable material that offers excellent heat dissipation properties, making it suitable for protecting electronic components. Additionally, aluminum sheets can be easily fabricated to create custom enclosures that provide electromagnetic shielding and protection against environmental factors.

- Q: Its been bugging me for years and i want to know why they say aluminum and not aluminium like it is spelt in the Oxford English dictionary and more importantly the universal periodic table, accepted by all countries, does anyone know why? I would like all opinions on this matter, if possible, thank you

- Because it's written Aluminum on the periodic table.

- Q: What are the benefits of using aluminum sheets?

- Using aluminum sheets in various applications offers several advantages. Firstly, aluminum sheets are lightweight, which makes them easy to handle and transport. This is particularly beneficial in industries like aerospace, automotive, and construction, where reducing weight is crucial for better fuel efficiency and overall performance. Secondly, aluminum sheets provide excellent resistance to corrosion. Unlike other metals, aluminum naturally develops a protective oxide layer when exposed to air, preventing further corrosion and enhancing durability. This makes aluminum sheets highly suitable for outdoor applications or in environments with high humidity or corrosive substances. Another advantage of aluminum sheets is their high strength-to-weight ratio. Aluminum is known for its exceptional strength, allowing it to withstand heavy loads or extreme conditions without compromising its structural integrity. This makes it an ideal choice for constructing lightweight yet sturdy structures, such as building facades, vehicles, or industrial equipment. Additionally, aluminum sheets are highly malleable and ductile, meaning they can easily be formed into various shapes and sizes. This flexibility allows for intricate designs and customization, making aluminum sheets highly versatile and adaptable to different manufacturing processes or project requirements. Furthermore, aluminum is a sustainable and environmentally friendly material. It is completely recyclable, meaning it can be reused repeatedly without losing its properties or quality. Recycling aluminum requires significantly less energy compared to primary aluminum production, resulting in reduced carbon emissions and a smaller environmental footprint. Lastly, aluminum sheets exhibit excellent thermal and electrical conductivity properties. This makes them suitable for applications that require efficient heat transfer or electrical conductivity, such as heat exchangers, solar panels, or electrical wires. In conclusion, the benefits of using aluminum sheets include their lightweight nature, corrosion resistance, high strength-to-weight ratio, malleability, sustainability, and excellent thermal and electrical conductivity. These advantages make aluminum sheets a popular choice in various industries, contributing to improved performance, cost-effectiveness, and environmental sustainability.

Send your message to us

10 Foot By 10 Foot of Aluminum Sheets 8xxx Hot Rolled

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords