Ultralight Beam Kanye Snl

Ultralight Beam Kanye Snl Related Searches

L Beam Steel Steel Lockers Durban Steel Gerter Aluminium H Beam Aluma Beam Capacity Bosch Beam Wiper Blades Kanye West Snl Ultralight Beam Ultralight Beam Kanye Snl Waler BeamHot Searches

Quick Form Scaffolding For Sale Buy Wood Screws Heated Wood Floors Cost Wood Trim Suppliers Alice In Chains Store H Type Scaffolding Electricity Generation By Fuel TypeUltralight Beam Kanye Snl Supplier & Manufacturer from China

Okorder.com is a professional Ultralight Beam Kanye Snl supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Ultralight Beam Kanye Snl firm in China.Hot Products

FAQ

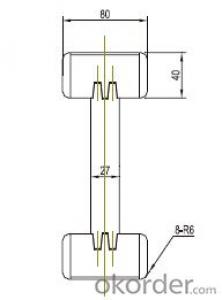

- How is I-beam connected?

- Put a splint on the left and right sides of the steel belly of the I-beam, drill out the equal hole in the splint and the steel belly, and fix with the high strength bolt. After that, the flange plate of the I-beam will be welded by welding. Generally, the holes are arranged vertically, and three sides can be used. The diameter depends on the height of the i-beam.

- What is the length of common I-beam?

- The length of the steel bar is generally 9m and 12m; the length of the I-beam and H section steel is generally 12m; the factory length of the angle steel is generally 6 meters; the common length of the channel steel is 6 meters, /8 meters and /9 meters.

- Yes, steel I-beams can be used in the construction of high-rise buildings. Steel I-beams offer excellent structural integrity and load-bearing capacity, making them a popular choice for constructing tall buildings. The I-beam's design allows for efficient distribution of weight and provides the necessary strength to support the multiple floors and heavy loads typically found in high-rise structures. Additionally, steel I-beams offer flexibility in design and can be easily fabricated and installed, making them a preferred choice for architects and engineers in constructing high-rise buildings.

- Steel I-beams are protected from corrosion through a variety of methods. One common method is the application of a protective coating. This coating can be in the form of paint, epoxy, or a zinc-based material. The coating acts as a barrier, preventing moisture and oxygen from reaching the metal surface and causing corrosion. Additionally, steel I-beams can also be galvanized. This process involves coating the beams with a layer of zinc, either through hot-dip galvanizing or electroplating. The zinc coating provides a sacrificial layer that corrodes in place of the steel, effectively protecting the I-beams from rust. Another method of corrosion protection is the use of cathodic protection. This involves connecting the steel I-beams to a sacrificial anode, such as zinc or aluminum, through a conductive material. The anode corrodes instead of the steel, preserving the integrity of the I-beams. Regular maintenance and inspection are also necessary to ensure that the protective measures remain intact and effective in preventing corrosion.

- Yes, there are building code requirements specific to steel I-beams. These codes outline the minimum size, strength, and structural integrity requirements for steel I-beams used in construction. They also specify the necessary connections, fasteners, and anchorage methods to ensure the safe and reliable performance of steel I-beams in buildings.

- Will the raw material of I-beam and channel steel be re examined?

- A formal manufacturer may require a warranty and should not be required. Irregular manufacturers, then they need to test their own or commissioned the test.

- Areas with high salinity or corrosive environments can pose challenges for steel I-beams, but proper protection and maintenance can help them perform well. Coastal regions and industrial areas, which are known for their high salinity and corrosive elements, can accelerate the corrosion process and potentially compromise the structural integrity of steel. To counteract the effects of high salinity and corrosion, steel I-beams are often coated with protective materials like galvanized coatings, epoxy coatings, or specialized paint systems. These coatings act as a barrier, preventing direct contact between the steel and the corrosive elements. Regular inspections and maintenance are also crucial to promptly identify and address any signs of corrosion. Nevertheless, it should be noted that even with protective coatings, steel I-beams in high salinity or corrosive environments may have a shorter lifespan compared to those in less corrosive environments. The severity of the environment, the quality of the coatings, and the maintenance practices all play significant roles in determining the performance and longevity of steel I-beams in such conditions. In extremely harsh environments, alternative materials such as stainless steel or fiberglass-reinforced polymers (FRP) may be considered, as they inherently possess greater resistance to corrosion. These materials offer extended durability and are commonly used in marine structures or other applications where corrosive conditions are prevalent. All in all, steel I-beams can still be a feasible choice in areas with high salinity or corrosive environments, as long as appropriate protective measures are taken and regular maintenance is carried out. Seeking guidance from structural engineers or corrosion specialists can help determine the most suitable approach to ensure the long-term performance and safety of steel I-beams in such conditions.

- Yes, steel I-beams can definitely be used for sports stadiums or arenas. Steel I-beams are commonly used in the construction of large structures like stadiums due to their high strength and load-bearing capabilities. They provide the necessary support and stability required to handle the weight of the structure, seating areas, and other components. Additionally, steel I-beams offer flexibility in the design and construction process, allowing for the creation of unique and innovative stadium structures.