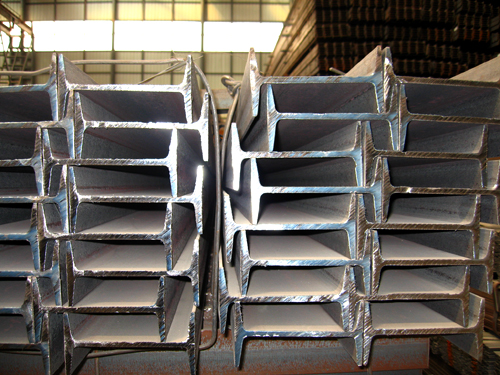

Metal Structure Steel I-beam High Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 4000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Quality Structural Steel I-Beam

OKorder is offering High Quality Structural Steel I-Beams at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

High Quality Structural Steel I-Beams are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (7-10 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Grade: Q235B, SM490, SS400, Q235B, Q345, Q345B

Production Process: Rolling cross-section

Dimensions:

Leg Height: 46 – 220mm

Depth: 50 – 180mm

Thickness: 4.5 – 17mm

Length: 6m – 12m

Production: 500 tons/month

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q:How do you calculate the moment capacity of a steel I-beam?

- In order to determine the moment capacity of a steel I-beam, various factors need to be taken into consideration. These factors include the dimensions of the beam, the properties of the material used, and the conditions under which it will be loaded. The moment capacity refers to the beam's ability to withstand bending forces. To begin with, one must ascertain the dimensions of the I-beam, including its height (h), the width of the flanges (b), the thickness of the flanges (tf), the thickness of the web (tw), and its length (L). These dimensions can either be obtained from the manufacturer's specifications or by directly measuring the beam. Next, one must determine the material properties of the steel, such as its yield strength (Fy) and elastic modulus (E). These values can also be obtained from the manufacturer's specifications or reference materials. Once the dimensions and material properties are known, the moment of inertia (I) of the beam can be calculated. The moment of inertia measures how the beam's mass is distributed around its axis and determines its resistance to bending. The following formula can be used to calculate the moment of inertia: I = (1/12) * (b * h^3 - (b - 2 * tf) * (h - 2 * tf)^3) + (Aweb * tw^2 * (h/2 - tw/2)^2) Here, Aweb represents the area of the web. After obtaining the moment of inertia, the section modulus (S) of the beam can be determined. The section modulus is a measure of the beam's resistance to bending and is calculated as: S = I / (h/2) Finally, the moment capacity (Mc) of the beam can be calculated using the following formula: Mc = Fy * S In conclusion, it should be noted that these calculations provide an estimate of the moment capacity. Actual results may vary due to factors such as material imperfections, manufacturing processes, and load distribution. Therefore, it is advisable to consult structural engineering codes and standards, as well as seek the guidance of professional engineers, to ensure accurate and safe calculations for specific applications.

- Q:Are steel I-beams prone to rust or corrosion?

- Yes, steel I-beams are prone to rust and corrosion. Steel is primarily made from iron, which is highly susceptible to rusting when exposed to moisture and oxygen. Over time, if not properly protected, the steel I-beams can develop rust and corrosion, which weakens their structural integrity. To prevent this, various protective coatings and treatments such as galvanization or painting are applied to the steel beams. These coatings act as a barrier, preventing moisture and oxygen from reaching the underlying steel and reducing the risk of rust and corrosion. Regular maintenance and inspection are also essential to identify and address any signs of rust or corrosion early on to ensure the continued strength and stability of the I-beams.

- Q:Can steel I-beams be used in theater stage construction?

- Yes, steel I-beams can be used in theater stage construction. Steel I-beams provide strong structural support, making them suitable for use in large-scale theater stages and platforms. They can withstand heavy loads, such as sets, props, and equipment, ensuring the safety and stability of the stage. Additionally, steel I-beams can be easily customized and fabricated to meet specific design requirements, allowing for flexibility in stage construction. Their durability and long lifespan make them a popular choice in theater stage construction, as they can withstand the demands of frequent use and provide a solid foundation for various performances and productions.

- Q:What are the considerations for connecting steel I-beams to concrete structures?

- When connecting steel I-beams to concrete structures, several considerations must be taken into account. Firstly, the appropriate connection method should be selected based on factors such as the load conditions, structural design, and construction requirements. It is crucial to ensure proper load transfer and structural integrity while considering factors like shear, moment, and torsion. Secondly, the connection design should consider the compatibility between the steel and concrete materials. This includes addressing potential differential movements between the two materials due to thermal expansion, shrinkage, or other factors. Adequate detailing and provision of expansion joints or flexible connections can mitigate these concerns. Thirdly, corrosion protection measures need to be implemented to prevent the steel I-beams from rusting or corroding when in contact with the concrete. This can include the use of protective coatings, galvanization, or the application of concrete cover to the steel elements. Lastly, the construction process should be planned to ensure proper installation and connection of the steel I-beams to the concrete structure. This may involve coordinating with other trades, such as concrete placement and formwork, to ensure accurate positioning and alignment of the beams. Overall, connecting steel I-beams to concrete structures requires careful consideration of load transfer, material compatibility, corrosion protection, and proper construction practices to ensure a safe and durable connection.

- Q:How do steel I-beams handle vibrations from nearby railways or highways?

- Steel I-beams are designed to handle vibrations from nearby railways or highways efficiently. The structural properties of steel, combined with the I-beam shape, allow them to effectively absorb and distribute vibrations, minimizing their impact on the overall structure. Additionally, steel has a high stiffness-to-weight ratio, making it more resistant to vibrations compared to other materials. Overall, steel I-beams are a reliable choice for withstanding vibrations caused by nearby railways or highways.

- Q:How do you calculate the shear deflection in a steel I-beam?

- To calculate the shear deflection in a steel I-beam, you need to consider the properties of the beam and the applied load. The shear deflection represents the amount of deformation or displacement that occurs perpendicular to the applied shear force. Here is a step-by-step process to calculate the shear deflection in a steel I-beam: 1. Determine the properties of the steel I-beam: You need to know the moment of inertia (I), the cross-sectional area (A), the length (L), and the modulus of elasticity (E) of the steel. 2. Determine the applied shear force: This is the external force acting on the beam that causes it to deform. It is usually represented by the symbol V. 3. Calculate the shear stress: The shear stress (τ) can be calculated by dividing the applied shear force by the cross-sectional area of the beam (τ = V / A). 4. Calculate the shear strain: The shear strain (γ) represents the deformation of the beam due to the applied shear force. It can be calculated by dividing the shear stress by the modulus of elasticity of the steel (γ = τ / E). 5. Calculate the shear deflection: The shear deflection (δ) is the displacement of the beam perpendicular to the applied shear force. It can be calculated using the following formula: δ = (V × L^3) / (3 × E × I). In this formula, V is the applied shear force, L is the length of the beam, E is the modulus of elasticity of the steel, and I is the moment of inertia of the beam. By following these steps and using the appropriate formulas, you can calculate the shear deflection in a steel I-beam. It is important to note that these calculations assume certain simplifications, such as the beam being homogenous and following linear elastic behavior. For more accurate results, advanced finite element analysis software or consulting an engineer may be necessary.

- Q:What are the cost implications of using steel I-beams in construction?

- The cost implications of using steel I-beams in construction can vary based on multiple factors. To begin with, the initial cost of steel I-beams is generally higher in comparison to alternative building materials like wood or concrete. This is due to steel being a premium material renowned for its strength, durability, and load-bearing capabilities, making it a preferred choice for supporting heavy structures. However, it's worth noting that steel I-beams tend to have a longer lifespan and require less maintenance than other materials, leading to potential cost savings in the long term. Moreover, the cost of utilizing steel I-beams in construction is influenced by the size and weight of the beams required for the project. Naturally, larger and heavier beams will be more expensive due to the increased amount of steel needed and the associated costs of transportation and handling. Another cost consideration is the installation process. Proper installation of steel I-beams necessitates specialized equipment and skilled labor, which can contribute to the overall project expenses. Nonetheless, the speed and ease of installation can offset these costs by reducing construction time and labor hours. Furthermore, steel is an adaptable material that can be easily recycled, adding to the sustainability aspect of using steel I-beams. This can result in potential cost savings through recycling incentives or reduced waste disposal fees. Overall, while the upfront cost of using steel I-beams in construction may be higher, the long-term benefits of durability, reduced maintenance, and potential sustainability advantages can outweigh the initial investment. It is crucial to carefully evaluate the specific project requirements, structural needs, and budget constraints to determine the most cost-effective solution.

- Q:Can steel I-beams be used in underground construction?

- Indeed, steel I-beams possess the capability to be utilized in underground construction. Owing to their remarkable strength, endurance, and ability to bear heavy loads, steel I-beams are frequently employed in various construction endeavors. When it comes to underground construction, where structures necessitate withstanding substantial pressure and supporting weighty loads, steel I-beams are often favored. They furnish exceptional structural reinforcement and find extensive application in the creation of tunnels, underground parking facilities, basements, and other subterranean structures. Moreover, steel I-beams can be tailored to meet specific project requirements, guaranteeing their suitability for the distinctive circumstances and complexities entailed in underground construction.

- Q:What can I do with welded I-beam and welded H?

- First of all, from the shape of: I-beam, each model has only two kinds, an ordinary type, and one is light, but light, rarely used.Type H steel, one in three, wide flange, middle flange, narrow flange.Purpose: steel beams are generally used for beams.Type H steel is generally used for columns, especially wide flange shaped steel, with mid flange and narrow flange for beams.The performance of H steel is higher than that of I-beam, but it saves material.As the beam, if the requirements of large vertical bearing capacity, generally with the high section type I-beam, and large horizontal force to the stability of the plane, generally using H steel, but the personal experience, to take in the flange is generally enough.About welding: as for the welding problem mentioned by landlord, there is no problem, H steel also has fillet, and avoid fillet when welding.

- Q:Can steel I-beams be used in exterior applications?

- Yes, steel I-beams can be used in exterior applications. Steel I-beams are commonly used in construction for their strength and durability, making them suitable for exterior applications where load-bearing capabilities are required. They are often used in the construction of bridges, highways, and industrial buildings, as well as for supporting large structures such as stadiums and warehouses. Steel I-beams can withstand harsh weather conditions, including extreme temperatures, high winds, and heavy rain or snowfall, making them a reliable choice for outdoor applications. Additionally, steel can be coated or galvanized to protect against corrosion, further enhancing its suitability for exterior use.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Metal Structure Steel I-beam High Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 4000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords