I Beam Steel IPEAA Type Used for Mineral Site with Light Weight

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of I Beam Steel IPEAA Description:

I beam steel IPEAA is a beam with an I-shaped cross-section. The horizontal elements of the "I" are known as flanges, while the vertical element is termed the "web". I beam steel IPEAA is usually made of structural steel and is used in construction and civil engineering. The I beam steel IPEAA resists shear forces, while the flanges resist most of the bending moment experienced by the beam. I beam steel IPEAA theory shows that the I-shaped section is a very efficient form for carrying both bending and shears loads in the plane of the web.

2. Main Features of I Beam Steel IPEAA:

• Grade: Q235

• Type: Mild carbon steel

• Deflection: The stiffness of the I-beam will be chosen to minimize deformation

• Vibration: The stiffness and mass are chosen to prevent unacceptable vibrations, particularly in settings sensitive to vibrations, such as offices and libraries.

• Local yield: Caused by concentrated loads, such as at the beam's point of support.

3. I Beam Steel IPEAA Images:

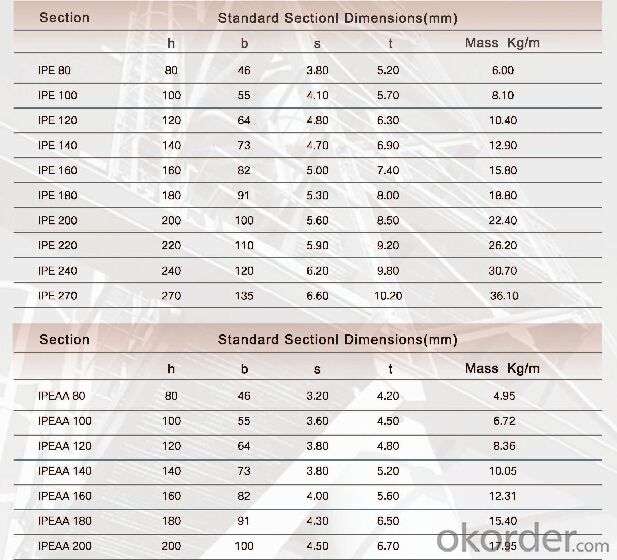

4. I Beam Steel IPEAA Specification:

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①Is this product same as W beam?

In the United States, the most commonly mentioned I-beam is the wide-flange (W) shape. These beams have flanges in which the planes are nearly parallel. Other I-beams include American Standard (designated S) shapes, in which flange surfaces are not parallel, and H-piles (designated HP), which are typically used as pile foundations. Wide-flange shapes are available in grade ASTM A992,[4] which has generally replaced the older ASTM grades A572 and A36.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③Is there any advantage about this kind of product?

Steel I beam bar IPE has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion, for which hollow structural sections are often preferred.

- Q:How are steel I-beams supported during installation?

- Steel I-beams are typically supported during installation using a combination of temporary supports and lifting equipment. Before installation, the I-beams are carefully positioned and aligned according to the construction plans. Temporary supports, such as adjustable steel columns or wooden cribbing, are then strategically placed under the beams to provide immediate stability and prevent any sagging or movement during the installation process. To lift and maneuver the I-beams into place, different types of lifting equipment are used depending on the size and weight of the beams. Cranes and hoists are commonly utilized, providing the necessary strength and control to lift the heavy steel beams safely. The lifting equipment is carefully positioned and secured to ensure stability during the installation process. Once the I-beams are lifted into position, they are further supported by connecting them to the surrounding structure. This can be done through various methods, including welding, bolting, or using specialized connectors. These connections provide additional stability and ensure that the I-beams are securely fastened to the building or structure. Throughout the installation process, proper safety measures are taken to protect the workers and ensure a successful installation. This includes using personal protective equipment, following safety protocols, and working in coordination with a skilled team of professionals. By carefully planning and executing the installation process, steel I-beams can be effectively supported and installed, providing a strong and reliable structural element for various construction projects.

- Q:Can steel I-beams be used in outdoor applications?

- Certainly! Outdoor applications can indeed make use of steel I-beams. These beams are renowned for their robustness and endurance, rendering them suitable for a wide range of construction endeavors, including those set in the open air. Bridges, building frames, and support structures are among the many outdoor constructions where steel I-beams are commonly employed. Steel possesses resistance against weather elements such as rainfall, gusts of wind, and extreme temperatures, making it particularly well-suited for outdoor deployment. Furthermore, steel can undergo treatment or coating processes to furnish additional defense against corrosion and rust, thus ensuring its long lifespan amidst outdoor surroundings. Ultimately, on account of their strength, durability, and capacity to withstand various weather conditions, steel I-beams represent a dependable and adaptable choice for outdoor applications.

- Q:What are the considerations for connecting steel I-beams to concrete structures?

- When connecting steel I-beams to concrete structures, several considerations must be taken into account. Firstly, the appropriate connection method should be selected based on factors such as the load conditions, structural design, and construction requirements. It is crucial to ensure proper load transfer and structural integrity while considering factors like shear, moment, and torsion. Secondly, the connection design should consider the compatibility between the steel and concrete materials. This includes addressing potential differential movements between the two materials due to thermal expansion, shrinkage, or other factors. Adequate detailing and provision of expansion joints or flexible connections can mitigate these concerns. Thirdly, corrosion protection measures need to be implemented to prevent the steel I-beams from rusting or corroding when in contact with the concrete. This can include the use of protective coatings, galvanization, or the application of concrete cover to the steel elements. Lastly, the construction process should be planned to ensure proper installation and connection of the steel I-beams to the concrete structure. This may involve coordinating with other trades, such as concrete placement and formwork, to ensure accurate positioning and alignment of the beams. Overall, connecting steel I-beams to concrete structures requires careful consideration of load transfer, material compatibility, corrosion protection, and proper construction practices to ensure a safe and durable connection.

- Q:What are the different types of steel coatings used for I-beams?

- There are several different types of steel coatings that are commonly used for I-beams. These coatings are applied to the steel to provide protection against corrosion and enhance the durability and longevity of the beams. One of the most common types of steel coating used for I-beams is hot-dip galvanizing. This involves dipping the beams in a bath of molten zinc, which forms a protective layer on the surface of the steel. Hot-dip galvanizing provides excellent corrosion resistance and is particularly well-suited for outdoor applications or environments with high levels of moisture. Another type of steel coating used for I-beams is epoxy coating. This involves applying a layer of epoxy paint to the surface of the beams. Epoxy coatings provide a strong barrier against corrosion and can be customized to meet specific requirements, such as high chemical resistance or fire resistance. Zinc-rich paint coatings are also commonly used for I-beams. These coatings contain a high concentration of zinc particles, which provide cathodic protection to the steel. The zinc particles act as sacrificial anodes, corroding in place of the steel and extending its lifespan. In addition to these coatings, there are also thermal spray coatings, such as metallizing or flame spraying, which involve applying a layer of molten metal onto the surface of the beams. These coatings provide excellent protection against corrosion and can be tailored to meet specific performance requirements. Overall, the choice of steel coating for I-beams will depend on factors such as the desired level of corrosion resistance, the environmental conditions the beams will be exposed to, and any specific performance requirements. It is important to consult with a professional coating specialist to determine the most suitable coating for a particular application.

- Q:In the welding of steel structure, the welding between I-beam and stiffener needs three sides to be welded

- The welding between the I-beam and the stiffener can strengthen the action! Intermittent welding in visual condition.

- Q:What does welded I-beam I400*1200*12*20 mean?

- Both sides are flat wide and 400mm with 12mm thick platesThe total height is 1200mm, and the middle ribs are 20mm thick plates

- Q:Are steel I-beams resistant to pests, such as termites?

- Yes, steel I-beams are highly resistant to pests, including termites. Unlike wood, which is susceptible to termite infestation, steel does not provide a food source or habitat for pests. This makes steel I-beams an excellent choice for construction in termite-prone areas. Additionally, steel is also resistant to other pests such as rodents, ants, and beetles, offering greater durability and longevity compared to alternative materials.

- Q:Can steel I-beams be used for food processing plants?

- Yes, steel I-beams can be used for food processing plants. Steel I-beams provide structural support and are commonly used in industrial settings, including food processing plants, where they offer strength, durability, and stability for various equipment and infrastructure.

- Q:How do you determine the required size of a steel I-beam for a specific application?

- To determine the required size of a steel I-beam for a specific application, several factors need to be considered. Firstly, the load that the I-beam will be supporting must be determined. This includes both the dead load, which is the weight of the structure itself, and the live load, which is the weight of any additional objects or people that will be placed on the structure. It is important to accurately calculate the total load to avoid overloading the I-beam and compromising its structural integrity. Next, the span length of the I-beam needs to be determined. This refers to the distance between the supports on either end of the beam. The longer the span, the larger the I-beam size will need to be to ensure adequate support. Another important consideration is the material properties of the steel being used. Different grades of steel have different strength and stiffness characteristics. The yield strength, ultimate strength, and modulus of elasticity should be taken into account when selecting the appropriate I-beam size. There are various design codes and standards that provide guidelines for determining the required size of a steel I-beam. These codes take into account factors such as the load, span length, and material properties mentioned above. Consulting these codes, such as the American Institute of Steel Construction (AISC) Manual, can help in determining the appropriate I-beam size based on the specific application. Additionally, computer-aided design (CAD) software and structural analysis programs can be utilized to simulate the loads and stresses on the I-beam. These tools can provide valuable insights and assist in selecting the suitable I-beam size. In summary, determining the required size of a steel I-beam for a specific application involves considering factors such as the load, span length, material properties, and following relevant design codes and standards. It is important to ensure that the selected I-beam is capable of safely supporting the expected loads and maintaining the structural integrity of the application.

- Q:What are the different types of steel reinforcements for I-beams?

- There are several types of steel reinforcements commonly used for I-beams, including plain carbon steel, low-alloy steel, high-strength low-alloy steel, and stainless steel. Each type offers specific properties and advantages depending on the required strength, durability, and corrosion resistance for the intended application.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

I Beam Steel IPEAA Type Used for Mineral Site with Light Weight

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords