IPEAA IPE/ beam steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

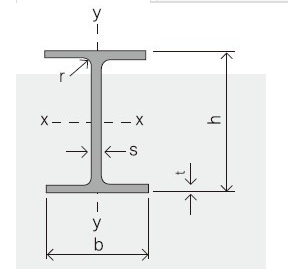

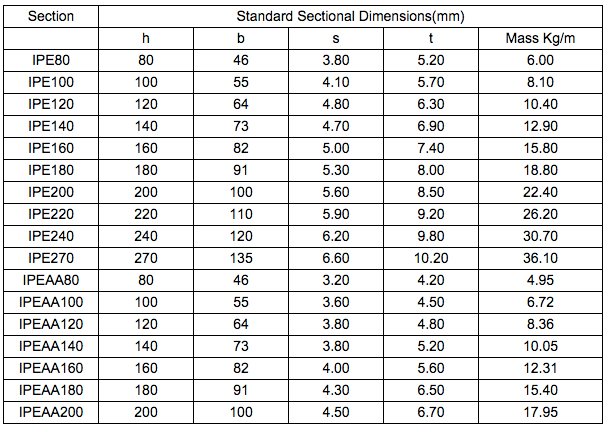

Specifications of IPE/IPEAA Beam Steel

1. Product name: IPE/IPEAA Beam Steel

2. Standard: EN10025, GB Standard, ASTM, JIS etc.

3. Grade: Q235B, A36, S235JR, Q345, SS400 or other equivalent.

4. Length: 5.8M, 6M, 9M, 10M, 12M or as your requirements

Applications of IPE/IPEAA Beam Steel

IPE/IPEAA Beam Steel are widely used in various construction structures, bridges, autos, brackets, mechanisms and so on.

Packing & Delivery Terms of IPE/IPEAA Beam Steel

1. Package: All the IPE/IPEAA Beam Steel will be tired by wire rod in bundles

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Shipment: In containers or in bulk cargo

5. Delivery time: All the IPE/IPEAA Beam Steel will be at the port of the shipment within 45 days after receiving the L/C at sight ot the advance pyment.

6. Payment: L/C at sight; 30% advance payment before production, 70% before shipment by T/T, etc.

Production flow of IPE/IPEAA Beams

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q:Can steel I-beams be used for overhead crane systems?

- Yes, steel I-beams can be used for overhead crane systems. Steel I-beams are commonly used as the main structural component for overhead crane systems due to their strength and durability. These beams are designed to support heavy loads and can be customized to meet the specific requirements of the crane system. Additionally, steel I-beams provide excellent resistance to bending and twisting forces, making them suitable for supporting the weight and movement of the crane and its load. They are also versatile and can be easily integrated into the overall design of the crane system. Overall, steel I-beams are a popular choice for overhead crane systems due to their reliability and ability to handle heavy loads.

- Q:What are the different surface finishes available for steel I-beams?

- The different surface finishes available for steel I-beams include hot-dip galvanizing, painting, powder coating, and epoxy coating.

- Q:What are the disadvantages of using steel I-beams in construction?

- One of the main disadvantages of using steel I-beams in construction is their susceptibility to corrosion. Steel is prone to rust, especially in humid or coastal environments, which can weaken the structural integrity of the beams over time. Additionally, steel I-beams are heavy and require specialized equipment for transportation and installation, which can increase construction costs. Moreover, steel can conduct heat and cold, making I-beams less energy efficient and potentially leading to higher heating or cooling costs.

- Q:How are steel I-beams measured and classified?

- Steel I-beams undergo measurement and classification based on their dimensions and properties. Typically, an I-beam's measurement encompasses height, flange width, web thickness, and flange thickness. Height refers to the vertical distance from the beam's top to bottom, while flange width represents the horizontal distance between the flanges' outer edges. Web thickness pertains to the width of the beam's central vertical section, and flange thickness denotes the thickness of the top and bottom horizontal sections. I-beams receive classification according to their size, shape, and strength. The American Institute of Steel Construction (AISC) provides a standardized system for I-beam classification, utilizing designations like S, HP, W, C, and MC. The S designation is for standard I-beams, with HP representing "wide flange" or "H-shaped" beams. W beams possess wider flanges than standard I-beams, while C beams have smaller flanges. MC beams, also called "channels," exhibit a C-shaped profile. Moreover, I-beam classification considers load-bearing capacity and bending strength. These factors are determined through calculation of the beam's moment of inertia and section modulus based on its dimensions. Structural engineers rely on these properties to select the appropriate I-beam for specific applications, ensuring it can support required loads and withstand bending or deflection. Apart from standard measurements and classifications, I-beams may have supplementary specifications like material grade and surface finish. Material grade signifies the steel's quality and strength, spanning from low-grade to high-strength alloys. Surface finish ranges from rough mill finish to painted or galvanized coatings, depending on desired appearance and corrosion resistance. Overall, the measurement and classification of steel I-beams involve evaluating dimensions, properties, load-bearing capacity, and strength. This information proves indispensable for engineers and architects in designing and constructing secure and efficient structures.

- Q:Do Steel I-Beams require special handling during installation?

- Yes, Steel I-Beams do require special handling during installation. They are heavy and cumbersome, so proper lifting equipment and techniques are essential to ensure safe and precise placement. Additionally, careful attention must be given to their structural integrity and alignment to prevent any potential damage or compromise to the overall stability of the structure.

- Q:How do steel I-beams perform in terms of seismic isolation?

- Steel I-beams can provide some level of seismic isolation due to their inherent strength and durability. However, they are not specifically designed for seismic isolation and may not perform as effectively as specialized seismic isolation systems. To enhance their performance, additional measures such as damping devices or base isolators may need to be incorporated into the overall structural design.

- Q:Are steel I-beams resistant to UV radiation?

- No, steel I-beams are not inherently resistant to UV radiation.

- Q:How are steel I-beams protected against galvanic corrosion?

- Galvanic corrosion is prevented in steel I-beams through galvanization. This process involves adding a layer of zinc to the surface of the steel beam. Typically, the steel beam is dipped in molten zinc in a hot-dip galvanizing process. The zinc bonds with the steel, creating a barrier that shields it from corrosion. The zinc coating acts as a sacrificial anode, meaning it corrodes before the steel when exposed to corrosive elements. This sacrificial corrosion of the zinc prevents the steel from being exposed to corrosive agents, thus extending the lifespan of the steel I-beam. Additionally, the zinc coating acts as a physical barrier, preventing moisture, oxygen, and other corrosive substances from reaching the steel surface. The thickness of the zinc coating can vary depending on the required level of protection. Thicker coatings are commonly used in highly corrosive environments, while thinner coatings may suffice for less aggressive conditions. Regular inspection and maintenance of the zinc coating, such as removing accumulated dirt or debris, are also crucial to ensure its effectiveness in preventing galvanic corrosion. In conclusion, steel I-beams are safeguarded against galvanic corrosion by applying a zinc coating through galvanization. This protective layer functions as a sacrificial anode, corroding instead of the steel and preventing corrosive agents from reaching the steel surface. Ongoing maintenance and inspection of the zinc coating are vital to guarantee its long-term effectiveness in preventing galvanic corrosion.

- Q:What's the name of the U steel for the fixed I-beam?

- You may see it above the steel structure. Generally, channel steel is used. That's the U type, but the section is generally upright and looks like a C.

- Q:How do steel I-beams contribute to the overall cost-effectiveness of a construction project?

- There are several ways in which steel I-beams contribute to the overall cost-effectiveness of a construction project. To begin with, their exceptional strength and durability enable the construction of structures that can withstand heavy loads and harsh weather conditions. This means that fewer beams are necessary to support the same weight compared to other materials, resulting in savings on both materials and labor. Moreover, steel I-beams offer great versatility and can be easily fabricated and customized to meet specific project requirements. They can be cut, welded, and shaped to fit different designs and structural needs, thereby reducing waste and eliminating the need for excessive on-site modifications. This adaptability also facilitates quicker construction, reducing labor costs and project timelines. Additionally, steel I-beams boast a long lifespan and require minimal maintenance when compared to other materials. They are highly resistant to corrosion, pests, and fire, thereby reducing the need for regular repairs and replacements. This longevity translates into long-term cost savings for the project owner, as there is less expenditure on maintenance and replacement over the life cycle of the structure. Lastly, steel I-beams are readily available from various suppliers, making them a cost-effective choice for construction projects. The competitive market for steel materials ensures reasonable pricing and access to a wide range of options, enabling project managers to select the most cost-efficient solution that meets their quality requirements. In summary, the utilization of steel I-beams in construction projects improves cost-effectiveness by reducing material and labor costs, facilitating faster construction, minimizing maintenance needs, and providing affordable options.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

IPEAA IPE/ beam steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords