Steel I Beam IPE in Chinese Standard and European Standard for Asia and Africa

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Steel I Beam IPE Description:

Steel I beam IPE is a beam with an I-shaped cross-section. The horizontal elements of the "I" are known as flanges, while the vertical element is termed the "web". Steel I beam IPE is usually made of structural steel and is used in construction and civil engineering. The Steel I beam IPE resists shear forces, while the flanges resist most of the bending moment experienced by the beam. Steel I beam IPE theory shows that the I-shaped section is a very efficient form for carrying both bending and shears loads in the plane of the web.

2. Main Features of Steel I Beam IPE:

• Grade: Q235

• Type: Mild carbon steel

• Deflection: The stiffness of the I-beam will be chosen to minimize deformation

• Vibration: The stiffness and mass are chosen to prevent unacceptable vibrations, particularly in settings sensitive to vibrations, such as offices and libraries.

• Local yield: Caused by concentrated loads, such as at the beam's point of support.

3. Steel I Beam IPE Images:

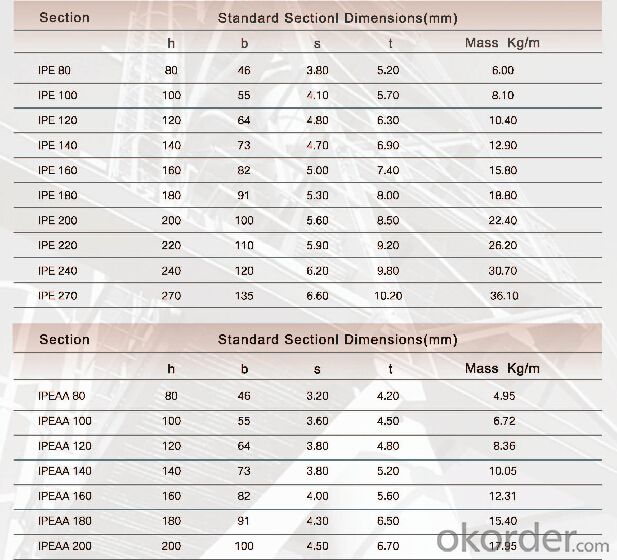

4. Steel I Beam IPE Specification:

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①Is this product same as W beam?

In the United States, the most commonly mentioned I-beam is the wide-flange (W) shape. These beams have flanges in which the planes are nearly parallel. Other I-beams include American Standard (designated S) shapes, in which flange surfaces are not parallel, and H-piles (designated HP), which are typically used as pile foundations. Wide-flange shapes are available in grade ASTM A992,[4] which has generally replaced the older ASTM grades A572 and A36.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.③Is there any advantage about this kind of product?

Steel I beam bar IPE has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion, for which hollow structural sections are often preferred.

- Q:How do steel I-beams perform in high temperature environments?

- Due to their exceptional heat resistance properties, steel I-beams exhibit excellent performance in high temperature surroundings. With a high melting point, steel maintains its strength and structural integrity until it reaches extremely high temperatures, typically surpassing 1000 degrees Celsius (1832 degrees Fahrenheit). In environments with elevated temperatures, the load-bearing capacity and structural stability of steel I-beams remain intact. This is primarily attributed to steel's remarkable heat conductivity, which allows for even distribution of heat throughout the entire structure, preventing localized melting or weakening. Furthermore, steel I-beams possess a high thermal expansion coefficient, resulting in minimal expansion and contraction compared to other materials when exposed to temperature fluctuations. This attribute enables them to retain their shape and structural integrity under high temperatures, with minimal deformation. Moreover, steel I-beams demonstrate resistance to fire and heat, thanks to the presence of a protective layer known as fire-resistant coating or intumescent paint. Acting as an insulating barrier, this coating reduces heat transfer to the steel, delaying its temperature rise and providing additional protection. However, it is important to acknowledge that prolonged exposure to extremely high temperatures can still impact the performance of steel I-beams. Beyond their critical point, steel may experience strength deterioration and eventually deform or collapse. Therefore, in situations where temperatures exceed the designated operating range, additional precautions such as fire-resistant insulation or cooling systems may be necessary to ensure the safety and integrity of the steel I-beams.

- Q:What is the average lifespan of a steel I-beam?

- The average lifespan of a steel I-beam can vary depending on a range of factors such as the quality of the steel used, the environment in which it is installed, and the level of maintenance it receives. Generally, a well-maintained steel I-beam can last for several decades or even longer. With regular inspections, proper cleaning, and adequate protection against corrosion, a steel I-beam can have a lifespan of 50 years or more. However, in harsh environments with high levels of moisture, salt, or chemical exposure, the lifespan may be significantly shorter. It is important to consult with structural engineers and follow manufacturer guidelines to ensure the longevity of the steel I-beam.

- Q:Are there any alternatives to steel I-beams for structural support in construction?

- Yes, there are several alternatives to steel I-beams for structural support in construction. One alternative is the use of reinforced concrete beams. Reinforced concrete beams are made by embedding steel rebar within the concrete, providing both the compressive strength of concrete and the tensile strength of steel. This combination makes reinforced concrete beams highly durable and capable of withstanding heavy loads. Another alternative is the use of laminated timber beams, also known as glulam beams. Glulam beams are created by bonding together multiple layers of timber with adhesives, resulting in beams that are strong, lightweight, and aesthetically pleasing. Glulam beams offer a sustainable alternative to steel, as they are made from renewable resources and have a lower carbon footprint. Additionally, engineered wood products such as laminated veneer lumber (LVL) and parallel strand lumber (PSL) can be used as alternatives to steel I-beams. LVL is made by layering thin wood veneers and bonding them together with adhesives, creating a strong and dimensionally stable beam. PSL, on the other hand, is made by aligning wood strands and bonding them together, resulting in a beam with high strength and stiffness. Fiber-reinforced polymers (FRP) are also emerging as an alternative to steel I-beams. FRP composites consist of fibers embedded in a polymer matrix, such as carbon fiber reinforced polymer (CFRP) or glass fiber reinforced polymer (GFRP). These materials offer high strength-to-weight ratios, corrosion resistance, and excellent durability. However, they are still being researched and developed for widespread use in construction. Overall, while steel I-beams are commonly used for structural support in construction, there are several viable alternatives available, including reinforced concrete beams, laminated timber beams, engineered wood products, and fiber-reinforced polymers. The choice of alternative will depend on factors such as load requirements, design preferences, sustainability goals, and cost considerations.

- Q:What are the considerations for corrosion protection of steel I-beams in marine environments?

- There are several key factors to keep in mind when it comes to protecting steel I-beams from corrosion in marine environments. These factors are crucial to ensure the beams' longevity and structural integrity since exposure to saltwater and other corrosive elements can greatly accelerate the corrosion process. 1. Material Selection: It is essential to choose the right type of steel for corrosion protection in marine environments. Stainless steel and galvanized steel are commonly used due to their natural resistance to corrosion. Stainless steel contains chromium, which forms a passive protective layer on the surface, preventing the underlying metal from corroding. Galvanized steel is coated with a layer of zinc, which acts as a sacrificial barrier, protecting the steel beneath it from corrosion. 2. Coatings and Paints: The application of coatings or paints specifically designed for marine environments is another effective method of protecting steel I-beams from corrosion. Epoxy coatings, polyurethane paints, or marine-grade coatings can create an additional barrier against saltwater and moisture, preventing direct contact with the steel surface and reducing the risk of corrosion. 3. Cathodic Protection: The implementation of cathodic protection systems can be advantageous for steel I-beams in marine environments. Cathodic protection involves using sacrificial anodes or impressed current systems to provide a protective current that counteracts the natural corrosion process. Sacrificial anodes, typically made of zinc or aluminum, are attached to the steel beams and corrode instead of the beams themselves, sacrificing themselves to protect the underlying steel. 4. Maintenance and Inspection: Regular inspection and maintenance play a critical role in ensuring ongoing corrosion protection for steel I-beams in marine environments. Inspections should be conducted to identify any signs of corrosion, coating damage, or other issues that may compromise the beams' integrity. Prompt repairs or recoating should be carried out as necessary to prevent further corrosion. 5. Design Considerations: Proper design can also contribute to corrosion protection in marine environments. For example, avoiding water traps or ensuring proper drainage can prevent moisture accumulation, which can accelerate corrosion. Additionally, selecting appropriate coatings or materials for connections and fasteners is essential to ensure the entire structure is adequately protected from corrosion. All in all, the considerations for corrosion protection of steel I-beams in marine environments involve choosing suitable materials, applying protective coatings or paints, implementing cathodic protection systems, conducting regular maintenance and inspections, and incorporating corrosion-resistant design features. By addressing these considerations, the risk of corrosion and subsequent structural damage can be minimized, ensuring the longevity and reliability of the steel I-beams.

- Q:How are steel I-beams protected from corrosion?

- Steel I-beams are protected from corrosion through a process called galvanization. This involves coating the beams with a layer of zinc, which acts as a barrier between the steel and the corrosive elements in the environment. The zinc layer not only prevents direct contact between the steel and oxygen or moisture but also provides sacrificial protection by corroding in place of the steel. This galvanized coating significantly extends the lifespan of the I-beams and ensures their structural integrity over time.

- Q:Can steel I-beams be used in the construction of theaters and performance venues?

- Certainly! The utilization of steel I-beams is viable for the construction of theaters and performance venues. These beams are widely employed in construction ventures owing to their strength, durability, and versatility. They are particularly well-suited for expansive structures, like theaters and performance venues, where extensive spans are necessary to accommodate open spaces and unobstructed views for the audience. Steel I-beams possess the capability to endure heavy loads and offer structural stability, thus making them ideal for supporting the weight of large lighting rigs, sound systems, and other equipment utilized in theaters and performance venues. Moreover, steel I-beams can be easily fabricated and customized to meet the specific design prerequisites of the project, allowing for flexibility in the overall architectural design. Overall, the use of steel I-beams proves to be an exceptional choice for the construction of theaters and performance venues, ensuring safety, efficiency, and an aesthetically pleasing environment for audiences to relish.

- Q:How are steel I-beams sized and classified?

- Steel I-beams are sized and classified based on their dimensions, particularly their depth, width, and weight per foot. The size and classification of steel I-beams are determined by industry standards and specifications, such as the American Institute of Steel Construction (AISC) standards. These standards ensure that I-beams are designed and manufactured to support specific loads and structural requirements.

- Q:Can steel I-beams be used for industrial structures?

- Indeed, industrial structures can utilize steel I-beams. Due to their remarkable strength-to-weight ratio, steel I-beams find widespread use in the construction sector. This characteristic enables the construction of robust and sizable structures. Support systems for warehouses, manufacturing plants, and power plants necessitate a dependable and sturdy framework, which steel I-beams effortlessly deliver. Furthermore, steel I-beams offer versatility and can be readily tailored and fabricated to suit precise design specifications, rendering them a favored option for industrial construction endeavors.

- Q:Are there any environmental concerns associated with the production of steel I-beams?

- Yes, there are several environmental concerns associated with the production of steel I-beams. Firstly, the production of steel requires a significant amount of energy. This energy is often derived from non-renewable sources such as coal or natural gas, which contribute to greenhouse gas emissions and climate change. The extraction and transportation of these fossil fuels also have environmental impacts, including habitat destruction, air pollution, and water contamination. Additionally, the process of converting iron ore into steel involves several steps that can generate pollution and waste. For example, the extraction of iron ore can lead to deforestation, habitat destruction, and soil erosion. The mining process also requires water, and if not managed properly, it can result in water pollution and depletion. Furthermore, the production of steel I-beams involves a process called steelmaking, which typically requires the use of blast furnaces or electric arc furnaces. These furnaces emit pollutants such as carbon monoxide, sulfur dioxide, and nitrogen oxides, contributing to air pollution and acid rain. The steelmaking process also generates solid waste, including slag and dust, which can contain heavy metals and pose risks to human health and the environment if not properly managed. Finally, the transportation of steel I-beams can also have environmental impacts. The heavy weight and size of these beams often require large trucks or ships for transportation, which consume fossil fuels and contribute to air pollution and greenhouse gas emissions. To mitigate these environmental concerns, efforts have been made to improve the efficiency of steel production processes, reduce emissions, and promote the use of recycled steel. Recycling steel can significantly reduce the energy and raw material requirements, as well as the associated environmental impacts. Additionally, advancements in technology and the adoption of cleaner energy sources can help minimize the carbon footprint of steel production.

- Q:Can steel I-beams be used in modular construction?

- Yes, steel I-beams can be used in modular construction. They provide a strong structural support system and can be easily integrated into modular building designs.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel I Beam IPE in Chinese Standard and European Standard for Asia and Africa

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords