Glass Fiber Filler

Glass Fiber Filler Related Searches

Fiber Sheet For Roof Decorative Lights For Ceiling Wall Panels For Basement Marketplace For Construction Materials Retaining Wall With Geogrid Galvanized Steel Wall Panels Stainless Steel Peg Board Stainless Steel Wall Art Stainless Steel Wall Shelves Stainless Steel WallHot Searches

Used Foam Board Insulation For Sale Bags Of Cement For Sale Types Of Temporary Side Panels For Cement Deck Magnesium Oxide Board For Sale Hdf Board For Sale sintra board for sale Fiber Sheet Price In India Gypsum Board Price Per Sheet In India Fiber Roofing Sheets Price In Pakistan Plastic Fiber Sheet Price 5 8 Type X Gypsum Board Price Twin Wall Polycarbonate Sheet Price Hardiflex Fiber Cement Board Price Gypsum Board Partition Wall Price India Extruded Polystyrene Insulation Board Price Polyurethane Insulation Board Price White Melamine Board Price Black Melamine Board Price Pre Laminated Board Price List Durock Cement Board PriceGlass Fiber Filler Supplier & Manufacturer from China

Okorder.com is a professional Glass Fiber Filler supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Glass Fiber Filler firm in China.Hot Products

FAQ

- Fiberglass fabric is known for its excellent performance in extreme temperatures within HVAC systems. It is an ideal material for insulation due to its ability to withstand high temperatures without losing its structural integrity or insulation properties. In high-temperature environments, fiberglass fabric acts as a barrier, preventing the transfer of heat between different areas of the HVAC system. It effectively traps heat within the desired space, ensuring energy efficiency and minimizing heat loss. Similarly, in cold temperatures, fiberglass fabric acts as an insulator, preventing heat from escaping and maintaining a consistent temperature within the HVAC system. This helps to reduce energy consumption and ensures optimal performance. Additionally, fiberglass fabric is resistant to fire and does not release toxic gases when exposed to extreme temperatures. This makes it a safe choice for HVAC systems, as it does not contribute to the spread of fires or pose a health hazard in case of accidental overheating. Another advantage of fiberglass fabric in extreme temperatures is its durability and longevity. It does not degrade or deteriorate when exposed to high or low temperatures, making it suitable for long-term use in HVAC systems. It can withstand the thermal cycling that occurs within the system without losing its insulating properties or structural integrity. Overall, fiberglass fabric is a reliable and effective material for extreme temperatures in HVAC systems. It provides insulation, energy efficiency, safety, and durability, making it a popular choice for various HVAC applications.

- Fiberglass fabric is not typically used for making tablecloths. This type of fabric is known for its durability, strength, and heat resistance, making it more suitable for applications such as insulation, construction materials, or protective clothing. Tablecloths, on the other hand, are typically made from fabrics that are soft, lightweight, and easy to clean, such as cotton, linen, polyester, or blends of these materials. These fabrics provide a comfortable and aesthetically pleasing surface for dining and are better suited for tablecloth purposes.

- Does anyone know what kind of sculpture of glass fiber reinforced plastic sculpture is?

- First of all, strictly speaking, this is not a sculpture, but a process made of glass fiber reinforced plastic. Because the material is light, the production cost is relatively low, large so-called sculpture, with this craft is indeed cost-effective. In simple terms, the glass steel process to want to do what products, the first to have a real, such as plaster production, large sculpture, a hollow lining on the surface of plaster sculpture physical model, glass steel process on the basis of type (a process that must be done such as stripping a ball type, must be divided into two halves to release the same) make a mold, again handle this mold, including grinding and polishing and waxing here no longer supplement. The next step is to use the FRP process to make a material in this mold. So this is so simple, but the production of glass steel there are a lot of attention in the process, if you have their own interests, but also occasionally, rubber mold, wood, DIY gadgets or sculpture is a very happy thing.

- Indeed, outdoor cushions can be crafted with fiberglass fabric, which is renowned for its durability, strength, and ability to withstand diverse weather conditions. This fabric proves to be a fitting selection for outdoor purposes as it resists fading, UV rays, and mold, which are prevalent concerns for outdoor cushions. Moreover, fiberglass fabric often possesses water-resistant or water-repellent properties, rendering it ideal for outdoor use where cushions may encounter rain or other forms of moisture. Ultimately, fiberglass fabric provides a dependable and enduring choice for outdoor cushions, guaranteeing their ability to withstand the elements and uphold their superior quality throughout time.

- Yes, fiberglass fabric can be used for upholstery. Fiberglass fabric is a versatile material that offers several benefits for upholstery applications. It is known for its durability and resistance to wear and tear, making it suitable for high-traffic areas. Fiberglass fabric is also resistant to stains, mildew, and fading, which makes it a popular choice for outdoor furniture upholstery. Additionally, it can provide excellent support and structure to cushions and upholstery foam, ensuring longevity and comfort. However, it is important to note that fiberglass fabric may not be as soft or comfortable as other upholstery materials like cotton or polyester. Therefore, its use should be considered based on the specific requirements and preferences of the project.

- Fiberglass fabric is highly regarded for its impressive performance in terms of tensile strength. Tensile strength refers to a material's ability to withstand tension without breaking or deforming, and fiberglass fabric excels in this aspect. The strength of fiberglass fabric can be attributed to its composition, which consists of finely woven glass fibers. These fibers possess exceptional tensile strength, resulting in a strong and durable fabric. This makes fiberglass fabric ideal for applications that require resistance against pulling forces. Additionally, fiberglass fabric offers a high tensile strength-to-weight ratio, allowing it to withstand substantial amounts of tension without adding excessive weight to the structure. This characteristic is particularly advantageous in industries such as aerospace, automotive, construction, and marine, where lightweight yet sturdy materials are essential. Furthermore, fiberglass fabric maintains its tensile strength even when exposed to harsh environmental conditions, including extreme temperatures, moisture, and chemicals. This reliability makes it a preferred choice for applications that demand stability and longevity. It is important to note that the specific manufacturing process and type of glass fibers used can affect the tensile strength of fiberglass fabric. However, overall, fiberglass fabric is renowned for its exceptional tensile strength performance, making it highly favored in various industries and applications.

- Fiberglass fabric serves as a useful tool in reinforcing concrete. Crafted from delicate glass fibers, this lightweight and resilient material finds widespread application in different sectors, particularly construction. By incorporating fiberglass fabric in concrete reinforcement, the tensile strength and durability of the structure are significantly enhanced. The high strength-to-weight ratio of fiberglass fabric renders it especially advantageous for concrete reinforcement. Its exceptional resistance to corrosion, chemical damage, and weathering make it suitable for both indoor and outdoor usage. Moreover, its non-magnetic and non-conductive properties make it the preferred option in areas where concerns regarding electromagnetic interference or conductivity arise. The process of reinforcing concrete with fiberglass fabric involves strategically placing the fabric amidst the layers of wet concrete during construction. Acting as reinforcement, the fabric efficiently distributes tensile stresses throughout the entirety of the concrete structure, bolstering its strength and preventing cracks or fractures. Furthermore, fiberglass fabric proves relatively effortless to handle and install. It can be expertly tailored to meet specific reinforcement requirements, taking on various shapes and sizes. Its versatility is further demonstrated by its ability to adapt to complex forms, be it through molding or wrapping. Consequently, it finds practical application in a wide range of concrete structures, including beams, columns, walls, and slabs. All in all, fiberglass fabric emerges as a dependable and effective material for reinforcing concrete. It confers numerous benefits, such as high strength, corrosion resistance, and ease of installation. Its inclusion in concrete reinforcement enhances both the structural integrity and lifespan of the concrete, thereby solidifying its status as a favored choice within the construction industry.

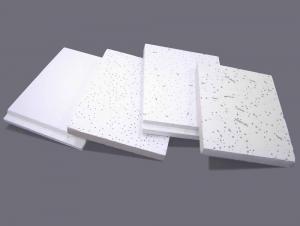

- Yes, fiberglass fabric can be used for making insulation boards. It is a common material choice due to its excellent thermal insulation properties and fire resistance. The fabric is typically combined with other materials and processed into insulation boards to enhance their energy-saving capabilities and provide effective heat insulation.