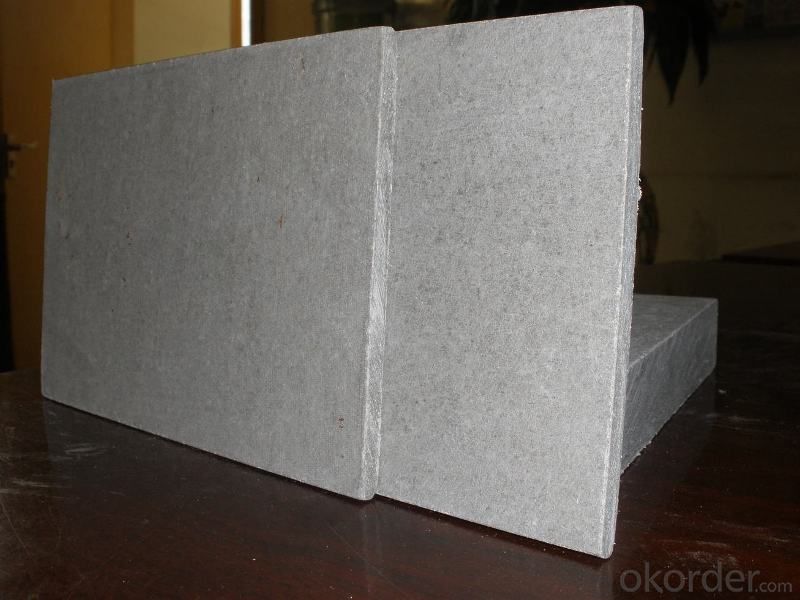

Exterior Wall Decorative Fiber Cement Board construction/drywall

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiber cement board, using high quality fiber and mineral substances as main content,was made with forming by advanced technique & technological process & through high temperature & high pressure maintenance & special treatment.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

5)stable dimensions

6)good heat and sound insulation

7)non-asbestos

8)mould resistant

9)no deformation

Main Product Features:

It's 100% free of asbestos, formaldehyde, benzene and other harmful substances and with excellent performance like high strength, large size, light weight, fire and water proofing, green and environmental friendly, high efficient and energy-saving. Therefore, this kind of new material is vigorously developed and recommended by the country.

Product Specifications:

FAQ:

1. Q:What is the different and most important point from other supplier?

A:We guarantee No asbestos if it has asbestos density will be more than 1.4g/cm3 what's more

3.2mm*3000*1220mm can be produced by us other suppliers can not do this size

2. Q:What are the advantages of your board?

A: outstanding light weight ,heat insulation, waterproof, fireproof, sound insulation, fast construction.

3. Q: Is the board fire resistant?

A: Yes, fire resistant 4 h , in the heat of 1000℃.actually it is noncombustible Class A1.

4. Q: Do you have any certificate to help us get government's approval?

A:China testing report and our laboratory' s testing by ourselves as your supporting document.

Because building standards are different in different countries, most of our customers buy the boards for testing and get approval by themselves.

5. Q: If we need samples for customer approval, will it be possible?

A: Of course we can.

6. Q:How to guarantee the quality?

A:Laboratory, integral testing process from raw materials to finished product until loading containers will be done by our factory.

Images:

- Q:Can the cement board cut off the wall directly

- Cement board partition wall directly scraping paint, will fall off. Cement board partition wall can not be directly putty putty, need to hang the network (as shown below), then spatula, scraping putty.

- Q:Ok, here's the situation:I have a covered porch on our house, and I need to replace its floor. Facts of concern: * It is a covered porch. There are four columns between the floor and roof, but I don't know whether they are actually supporting the roof. * It is currently floored with 1/2 plywood, which is rotting. No standing water involved; the texture prevents proper drainage and led to rot. * Under the porch is a basement room complete with wiring and such. We had planned to use oak tongue-in-groove, but have been warned away from it. Now we’re not sure what to use – we just know we don’t want to use plywood.Our questions:1. If I assume those beams are supporting the roof, I’ll need a jack. But what jack? Where do I rent one?2. I thought about using a thin plywood layer under some cement board, but what could I put on top, other than tile?3. Anybody have any other ideas for flooring? Where to get TIG cedar in Cleveland?Thanks!

- layer of sealed tarpaper [roofing tar in overlapped joints] + layer of pressure treated plywood on top fpr strength. i have old chipboard with sealed tarpaper over it + outdoor rug on my deck for 15 years. rug keeps wearing out only

- Q:Hi everybody! I just installed hardibacker boards in my bathroom. But I had to remove 1 pc 'coz I made a mistake. Can I still use it again? I screwed it every 8 inches around the edges and along every stud. Can I just cover the holes with thinset? Thanks!

- Yes, as long as you adequately fill the holes, you're good to go

- Q:How about wood wire cement board? Is it environmentally friendly building materials?

- The cement board is very good. It is environmentally friendly green building materials, from the cement as a cross-linking agent, wood as a fiber reinforced material, adding part of the additives made of the plate, mainly by the crushed wood and Portland cement gluing processing, color cleaning, double Smooth and smooth surface. The product combines the strength of wood, ease of processing and cement durable characteristics. Wood fiber cement board in the 40's began to be widely used in Europe, has now become a wide range of international application of building materials. It is versatile, excellent performance, with corrosion resistance, heat resistance, resistance to corrosion, easy processing, and cement, lime, gypsum with good, green and other advantages. Now, the Netherlands, Finland, Germany, Austria, Russia and other countries have formed a number of such special plate manufacturing company, as well as professional equipment manufacturers, compared to China's less such production lines, wood The development of the domestic space is relatively large, to be the depth of development and utilization.

- Q:Why plastic materials use glass fiber reinforced

- Its plastic is relatively brittle, in order to fall resistance, compression, increase strength and toughness. It is a reason to add steel to the inside of the cement board. Notebook shells usually add fiber.

- Q:why is gypsum always interground with cement clinker during the final stages of portland cement manufacture?

- Because they are trying to dispose of Gypsum and this is one of the few ways that it can be blended with something else in large quantities. Gypsum is produced as a by-product form the de-sulphurisation of flue gasses from power plants that still burn dirty fuels like coal or oil residues. There is often thousands of tons of this stuff produced every day and it has to be dumped somewhere. Land fill sites are filling up rapidly and charge big fees for disposal so it is very attractivce to belnd it into cement products. Gypsum is also used as the main part of plaster board which is another place to get rid of the unwanted material.

- Q:Do you need to finish a cement board for a shower like you would if it were drywall?

- Yes... Cement board can get wet but it's not meant to be soaked as it would be on a constant basis in a shower. You'll want to tile it.....

- Q:How does the cement pressure plate interface

- The corners of a corner, such as the four corners of a square room

- Q:What is the national standard for the thickness and hardness of indoor residential cement?

- The surface of the wall is the cement mortar leveling layer, the general thickness is not required, the mortar cement ratio, cement label, flatness and so on are required. Look at your situation, it should be cement mortar in the proportion of cement is too low, you can find the developer claims, but it is best private or to the local construction commission of the quality inspection station complaints, the court reluctant to accept these small cases, say the time Also can not afford to drag.

- Q:What is the fiber used for cement foaming?

- Polypropylene staple fiber can effectively enhance the toughness of concrete, effectively control the plastic shrinkage, shrinkage, temperature change and other factors caused by micro-cracking, to prevent and inhibit the formation and development of cracks, effectively improve the concrete / mortar cracking resistance Permeability and impact resistance, anti-abrasion, anti-freeze-thaw, seismic capacity.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Exterior Wall Decorative Fiber Cement Board construction/drywall

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords