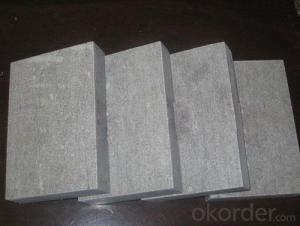

Fiber Cement Boards For Interior Wall Partition

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The raw materials of fiber cement board are cellulose fiber, silicate cement, quartz sand, water and some additives. It's a kind of high-tech product which formed through accurate dosing by computer program, hatschek craft and compressed by 14000tons hydraulic machine and autoclaved under high temperature and pressure.

Product Applications:

Fiber cement board can be used in exterior wall cladding and facade of various high-class and high rise civil buildings especially in the modern luxurious buildings. Outstanding sound insulation of the system composed with Bysink external wall board can be used in indoor partition and suspended ceiling for the high demand in private request as sound insulation and such as five star hotel, bedroom, and public entertainment.

Also it can be used as the interior partition in the shops, hotels, schools, entertainment places and hospitals.

Product Advantages:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

5)stable dimensions

6)good heat and sound insulation

7)non-asbestos

8)mould resistant

9)no deformation

Main Product Features:

100% asbestos free

Non-combustible:PSB GB8624 Grade A

Moisture resistant

Excellent impact resistance

Excellent sound insulation

High dimensional stability

Good surface finish

Product Specifications:

FAQ:

1. Which port do you choose for FOB ?

Answer: FOB Shanghai Port.

2. What's your delivery time of your products?

Answer: About 20 days after confirm the order.

3. What about the terms of payment?

Answer: 30%TT advanced payment, balance seven days before shipment.

Other terms of payments also can be negotiated.

4. What's your Minimum order quantity(MOQ) of your product?

Answer: Generally, MOQ is 1x20' container. Others can contact with me directly.

Images:

- Q:What does the glass wire add to the cement?

- The effect of adding glass cement can not only improve the alkali resistance of glass fiber, but also reduce the erosion of glass fiber. It is an early strength, high strength, low alkali, impermeability, corrosion resistance, freeze-thaw resistance, Micro-expansion and contraction, negative temperature construction, coloring and other properties in one, can inhibit the alkali - aggregate reaction of the 21st century new cement. After testing and calculation, the durability of alkali glass fiber in the composite of Portland cement is one year, and the composite alkali-resistant fiberglass fiber is 17 years. The glass fiber cement is 52 years, and the composite alkali-resistant glass fiber is 155 years.

- Q:What is the easiest way to hang cement board in a bathroom which will be tiled?

- Cement Board must be Securely Fastened to PRESSURE TREATED LUMBER or Metal Studs or Lats. Pre-Drill holes using a Masonry Drill BIT! Then fasten them using Stainless or Coated HARDWARE! Thanks, RR

- Q:I have a 5x20 room off my basement which sits under my front porch. All four walls of the room are cement block all the way up to the ceiling which is the cement slab from the porch above. There is a wood ceiling in the room that has gotten wet from leaks above. Is it safe to remove the wood joists and plywood in that room, fix the leaks and replace it? This doesn't support any weight from the slab above, does it? I assume that it was probably used as the bottom of the form when the slab was poured. Also, when I replace the ceiling, can I attach the ledger board using concrete sleeve anchors? Can these be fastened into the block wall? I'm not sure if they are hollow or have been filled with gravel or concrete. I plan on using the ledger board to fasten joist hanger to and frame back up my ceiling for insulation and wiring. The current ledger is attached with masonry nails. Any thoughts?

- Your ceiling may very well be no more than the bottom forms for the slab, but you really need to make sure. Attempting to seal the concrete slab from the underside isn't advisable. Concrete draws moisture, so you will always have a seepage problem after you're finished. I'd suggest sealing the slab on the surface and make sure it quit weeping before proceeding with the remainder of your project. Not all concrete blocks are filled. To secure your ledger board I'd suggest using a lag bolt with a lead spread type toggle. Drill into the block and insert to lead, which will hold the lag bolt. Hope this has been some help. Good Luck

- Q:i built a pair of cubed 2x4 tables,can i use cement board on top?then tile?

- With mastic cement you can stick tiles right to a wood surface providing it's flat. I used 6 floor tiles with mastic on cabinet grade plywood for our kitchen. It's lasted 17 years now. Mastic comes in plastic containers already mixed......you just trowel it on and stick your tile.

- Q:The scope of application of foam cement

- Pipeline backfill. Underground abandoned oil tanks, pipelines (built-in crude oil, chemicals), sewage pipes and other holes easily lead to fire or landslides, the use of foam concrete backfill can solve these troubles, the cost is also less. The density of foam concrete depends on the diameter of the pipe and the groundwater level, usually 600-1100kg / m? ;.

- Q:Do you need to finish a cement board for a shower like you would if it were drywall?

- Or since you already are going to have thin-set.... Use mesh tape and mud the tape in with thin-set....same thing.... works just as well. The primary reason for taping and mudding the joints is keeping moisture OUT its not a leveling out or cosmetic issue like drywall, make it flush and cover the tape with material and your ready to tile. DO NOT USE reg drywall mud it is not for wet applications.....

- Q:in my new bath/shower i'm using hardibacker cement board. what should i use for the rest of the bathroom walls

- Keep the two bath/ shower walls the same, the other two or more walls you can use WR board (water resistant gyprock) witch you can get from any plaster board shop or bunnings. Good luck!

- Q:The roof of the cement board everywhere cracked, how to do

- Roof cement board cracks, must wait until the sunny morning to do waterproof before the roof, it is recommended to use rigid flexible combination of flexible waterproof material plus rigid material effect is the best. Flexible materials to coil, linoleum-based.

- Q:How thick concrete boards are used in the room walls

- According to consumption standards, the general external wall plastering three layers, the bottom, middle, surface layer, the total thickness of the three layers in the 15 - 20MM, the thickest not over 25MM. Generally about 5MM bottom, the middle 5 - 12MM or so, the surface layer 2 --- 5MM.

- Q:I'm laying slate tile over linoleum that was installed about 6 months ago....the linoleum is in very good condition, very smooth with no rips or lifting. I've done some research and figured I could put down cement board and then lay the tile on that. The floor under the linoleum is cement. Is there a special drill/special screw necessary to attach the cement board to the cement foundation?

- Your best to remove the vinyl but it is a LOT of hard work and truly not needed if it is down tight and no air pockets etc.. No cement board is needed at all . A wasted expense.You really can rough up the vinyl w/ belt sander, and tile over the vinyl w/ proper thin set.. Allow an extra day or two to let the thin set dry since moisture has no where to go.. Make sure your use a damp sponge to wipe off back of slate since the way its cut it leaves a residue on the back ( dusty) that will not let thin set bond properly.. A gauged slate is easy to set just like any tile its the ungauged slate you ll have to be more carefull with.. Seal the slate at LEAST once before installing or thinset and grout may stain or be almost impossible to remove GL

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiber Cement Boards For Interior Wall Partition

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords