Customized Fiber Cement Board/ Wall Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

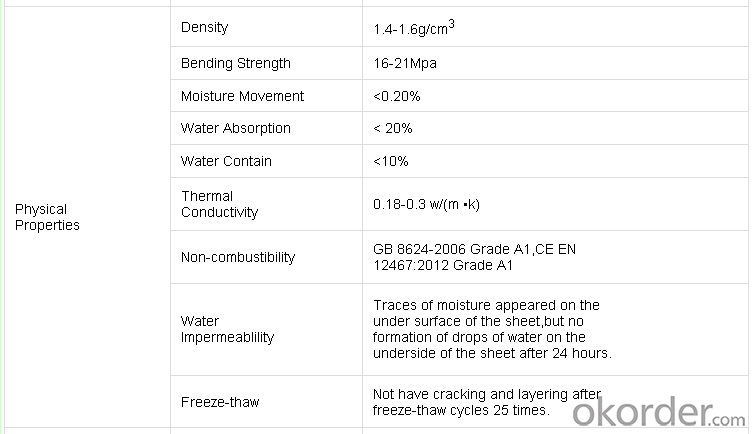

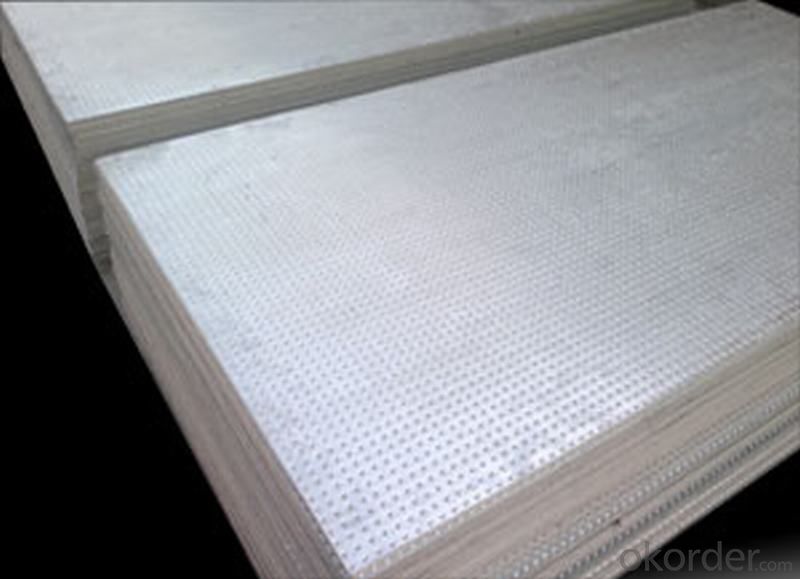

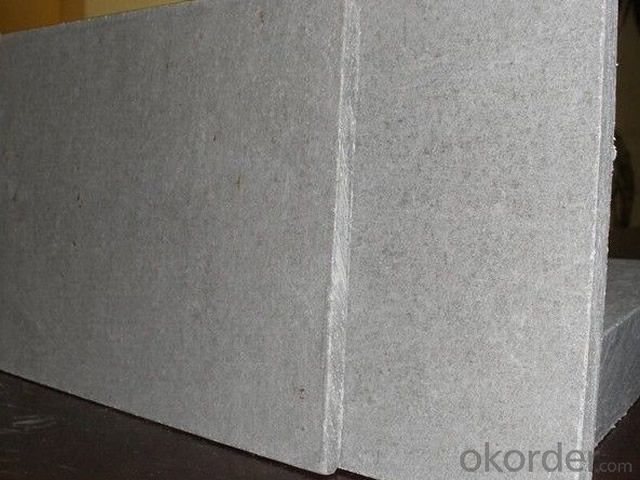

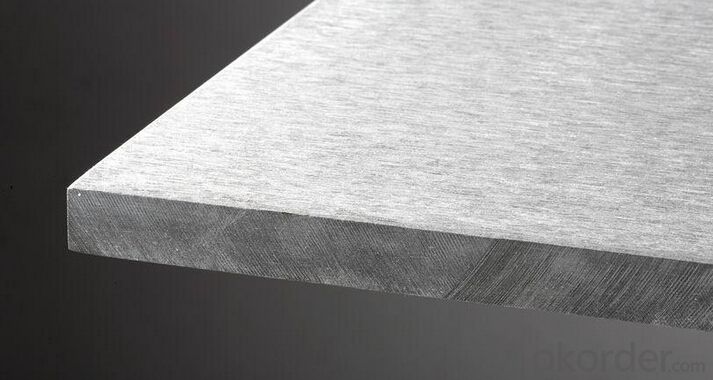

The raw materials of fiber cement board are cellulose fiber, silicate cement, quartz sand, water and some additives. It's a kind of hightech product which formed through accurate dosing by computer program, hatschek craft and compressed by 14000tons hydraulic machine and autoclaved under high temperature and pressure.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

5)stable dimensions

6)good heat and sound insulation

7)non-asbestos

8)mould resistant

9)no deformation

Main Product Features:

1) Incombustibility: It can not burn and give off toxic smoke.

2) Heat insulation: Low heat conductivity, good thermal insulation.

3) Waterproof: It can keep its shape without swelling and deformation after a long time.

4) Sound proof: Reduce indoor noise.

5) Environmental protection: high density reinforced fiber cement board `s special characters make more comfortable environment.

6) High Strength: High-stength and impact-resistant make it is not easy to be damaged.

7) Durability: insulation against bugs, fungus and corrosion,so reinforced fiber cement board can last for a long time.

8) Easy installation: Painting, tiling and nailing can be feasible in the new system.

Product Specifications:

FAQ:

1. Which port do you choose for FOB ?

Answer: FOB Shanghai Port.

2. What's your delivery time of your products?

Answer: About 20 days after confirm the order.

3. What about the terms of payment?

Answer: 30%TT advanced payment, balance seven days before shipment.

Other terms of payments also can be negotiated.

4. What's your Minimum order quantity(MOQ) of your product?

Answer: Generally, MOQ is 1x20' container. Others can contact with me directly.

Images:

- Q:Really stone paint the external walls, with ordinary cement board how to deal with the base, what materials to do

- External walls are generally used to deal with putty, specifically including the following steps (the above content are from the general source of paint official website related information):

- Q:Has anybody made a claim for and been paid for the cement board siding class action lawsuit?

- Dont okorder has some good examples of past class action lawsuits and for a really good read, read Grisham's the king of Torts. Right now I am actually a part of a class to recover FOREX fees on my credit card. I have lost probably a few hundred dollars i expect to be granted $5! Wahoo!

- Q:What are the standards for residential steel structures?

- For a long time, China's residential structure to brick and concrete structure and reinforced concrete structure. The traditional residential structure from the major, at the same time, due to the wall thickness, beam height, large column, and makes the space utilization is low, the opening depth is small, the arrangement is not flexible.

- Q:What are the prospects for the development of wood fiber cement board?

- Applications: decorative interior and exterior walls, floors, ceilings, furniture, soundproof walls, Portland cement and Portland cement are called outside the continent. Plate used in the cement should be superior to the wood are some paper mills out of the crude fiber is environmentally friendly raw materials. There are other auxiliary inorganic additives to join and the addition of quick-setting agents to ensure the quality of the product. Later in the building should be continuously improve the scope of application of its products than the impact of the plaster board is much stronger. After the market will flourish. From the gray board of smallpox to the application of gypsum board with a decade of time to promote.

- Q:My fear is that I will trap moisture where it shouldn't be. Is there such a thing as overkill?

- No problem. i dont call it overkill. I would rather do it know than wish i had.

- Q:I am trying to anchor a woody climbing wall to a cinder block garage wall and have settled on anchoring boards into the cinder blocks then building from there. so anything anchored there would be sharing a load of me-200 lbs, the plywood base and frame - 50lbs. plus any force generated by my jumping around on it.

- Cinder Block Anchor

- Q:i glued a piece of regular printer paper to a piece of matboard as part of an art project. since i applied rubber cement to both the paper and the board, it bonded quite strongly. the problem is that now i have to remove the paper with the least amount of damage to the matboard. the paper is white and the board is black. its been over a week since i glued the two together. HELP!! i need this for school and it has to look good...any suggestions??im going to throw the paper away, so that can be damaged in the process. no problem.

- Try pulling the paper off...and use your hand to ball up the rubber cement

- Q:i am having alotta trouble on the cement like i cant get both feet back on the board.any tips?

- I must adjust your kick flip on cement because your board will move more compared to grass. Another reason could be mental. You might be sabotaging yourself by over thinking it. I would recommend tightening your wheels so the have less movement while your practicing your kick flip.

- Q:Can cement board be used for floor decoration?

- A floor of the ground used: 1. tiles 2. flooring 3. marble you asked the shop where the shop shop black stone was here I tell you about my decoration experience, the store floor decoration generally use ordinary rows of tiles, The reason is: all ceramic tiles and marble cost is expensive, the general owner will not use

- Q:Can you put ceramic tile over wood floors? If yes I was told that it wouldnt stay, even with cement board.?

- It depends on what you mean by wood floors. If you are talking about placing the tile over an existing hardwood floor, then no the old floor is not a good foundation for the tile. If you are talking about placing the tile over a plywood subfloor, then yes, this is exceptable with most tile manufacturers.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Customized Fiber Cement Board/ Wall Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords