Thermal Insulation Silicone Coated Fiberglass Fabric

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description: Silicone coated fiberglass fabric is made by special formulated liquid or wet silicone rubber dispersed or calendered into the high quality fiberglass cloth and vulcanized, dried. This finished silicone fabric inherits the fiberglass insulation fabric's properties and also improve its fireproof, hand fabrication, oil and waterproof, abrasion resistance.

Features: Fireproof, Thermal Insulation, Abrasion Resistance, Waterproof

Application: Thermal Insulation Cover, Blanket, Jacket, Cover, Pad, Fabric Expansion Joint, Flexible Connector, Welding Blanket, Fire Blanket, Fireproof Curtain, Smoke Curtain

PRICE: USD3.5 per square meter

UNIT: square meter

MOQ: 500 square meter

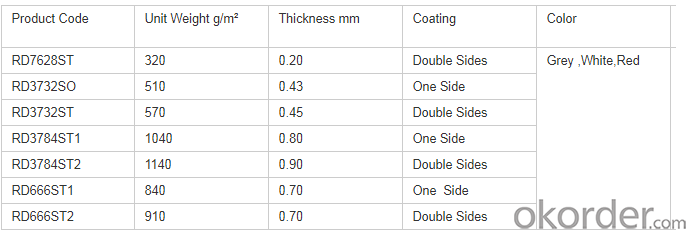

Weight: 140gsm-3000gsm

Width: 90mm to 2000mm or customized

Yarn Type: E-glass

Standing temperature -50℃-550℃

Product name: Silicone Coated Fiberglass Fabric

Coating/Finish/Surface Treatment: Silicone coated

Roll length: 50 meter or customized

Color: Grey, Red, Black, White, Salmon, Green, Blue, Yellow, or customized

Weave Type: Twill, Satin, plain woven or customized

Alkali content: alkali free

Processing service: cutting

Material: fiberglass

Thickness: 0.1mm to 3mm

Size: can be customized

Supply ability: 300000 meters per month

Packaging: Fiberglass fabric rolls packed in cartons loaded on pallets or according to customers' requirements.

Lead time: 7-30 days

- Q:Can fiberglass fabrics be used for reinforcement in 3D-printed objects?

- Yes, fiberglass fabrics can be used for reinforcement in 3D-printed objects. The fiberglass fabric can be embedded in the printing material to enhance the strength and durability of the finished object.

- Q:Can fiberglass fabric be used for heat-resistant blankets?

- Indeed, heat-resistant blankets can be made using fiberglass fabric. Fiberglass, a remarkably heat-resistant substance, has the ability to endure high temperatures without any signs of melting or deterioration. Its exceptional thermal insulation qualities make it an optimal selection for heat-resistant blankets. Fiberglass fabric blankets have diverse applications, including welding, foundries, fire protection, and heat shielding. These blankets deliver dependable defense against heat, flames, and sparks, making them a trustworthy option for environments where heat resistance is of utmost importance.

- Q:XHJ how about neoprene asphalt waterproof coating?

- Will the barrel stir, then pour in the pail with oil gun construction.

- Q:Does anyone know what kind of sculpture of glass fiber reinforced plastic sculpture is?

- First of all, strictly speaking, this is not a sculpture, but a process made of glass fiber reinforced plastic. Because the material is light, the production cost is relatively low, large so-called sculpture, with this craft is indeed cost-effective. In simple terms, the glass steel process to want to do what products, the first to have a real, such as plaster production, large sculpture, a hollow lining on the surface of plaster sculpture physical model, glass steel process on the basis of type (a process that must be done such as stripping a ball type, must be divided into two halves to release the same) make a mold, again handle this mold, including grinding and polishing and waxing here no longer supplement. The next step is to use the FRP process to make a material in this mold. So this is so simple, but the production of glass steel there are a lot of attention in the process, if you have their own interests, but also occasionally, rubber mold, wood, DIY gadgets or sculpture is a very happy thing.

- Q:Can fiberglass fabric be used for reinforcing plaster or stucco?

- Yes, fiberglass fabric can be used for reinforcing plaster or stucco. It provides strength and durability to the plaster or stucco, preventing cracking and improving its overall structural integrity.

- Q:What are the different fiberglass fabric finishes for water resistance?

- There are several different fiberglass fabric finishes that can enhance water resistance, such as silicone, polyurethane, acrylic, PTFE (Teflon), and vinyl coatings. These finishes create a protective barrier on the fabric surface, preventing water penetration and increasing durability in wet conditions.

- Q:Can fiberglass fabric be used for making sports jerseys?

- Yes, fiberglass fabric can be used for making sports jerseys. It is a strong and durable material that offers excellent resistance to wear and tear. However, it may not be commonly used for sports jerseys due to its lack of breathability and potential discomfort for athletes.

- Q:What are the disadvantages of using fiberglass fabric?

- There are a few disadvantages of using fiberglass fabric that should be considered. Firstly, fiberglass fabric can cause skin irritation and respiratory issues if proper protective measures are not taken. The fine fibers of fiberglass can become airborne during the fabrication process or when the fabric is cut or manipulated, leading to the potential inhalation of these fibers. This can result in respiratory problems such as coughing, wheezing, and even more serious conditions like fibrosis or lung cancer. Therefore, it is crucial to wear appropriate protective clothing and masks when working with fiberglass fabric. Secondly, fiberglass fabric is not as flexible or malleable as other fabric materials. It is stiff and can be difficult to shape and mold, especially when compared to fabrics like cotton or polyester. This limits its applications in certain industries where flexibility and conformability are important, such as in the manufacturing of clothing or upholstery. Additionally, fiberglass fabric is prone to breakage and damage. While it is known for its strength and durability, it can become brittle over time or when exposed to extreme temperatures. This can result in cracking or fracturing of the fabric, reducing its effectiveness and lifespan. Regular maintenance and careful handling are necessary to prevent such damage. Another disadvantage of fiberglass fabric is its poor resistance to UV radiation. Continuous exposure to sunlight can cause the fabric to degrade and lose its strength and structural integrity. This makes it unsuitable for outdoor applications where prolonged exposure to sunlight is expected, such as in construction or marine industries. Lastly, fiberglass fabric is a poor conductor of electricity. While this can be an advantage in certain situations, it can also be a disadvantage when electrical conductivity is required. This limitation can restrict its use in applications where electrical grounding or conductivity is essential. In summary, the disadvantages of using fiberglass fabric include potential health hazards if proper precautions are not taken, limited flexibility and malleability, susceptibility to breakage and damage, poor resistance to UV radiation, and low electrical conductivity. These factors should be carefully considered when deciding on the appropriate fabric material for a specific application.

- Q:What is the typical thickness range for fiberglass fabrics?

- The thickness of fiberglass fabrics can vary depending on the specific application and intended use. Generally, the range of thickness for fiberglass fabrics is from approximately 0.2 millimeters (0.008 inches) to 1.5 millimeters (0.06 inches). Lightweight applications like surfboard or boat manufacturing typically require thinner fabrics, whereas thicker fabrics are suitable for heavy-duty applications such as automotive or industrial insulation. It is important to understand that the thickness of fiberglass fabrics can be customized for each project, as there is no universal solution.

- Q:How is fiberglass fabric stored and handled?

- Fiberglass fabric is typically stored and handled in a dry and temperature-controlled environment to prevent moisture absorption and damage. It should be kept away from direct sunlight and stored upright on racks or pallets to avoid creasing or crushing. When handling fiberglass fabric, it is important to wear protective gloves and a dust mask to prevent skin irritation and inhalation of fiberglass particles. Additionally, it should be handled gently to avoid tearing or fraying, and any sharp objects or rough surfaces should be avoided during the handling process.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Thermal Insulation Silicone Coated Fiberglass Fabric

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords