High Temperature Thermal Insulation Texturized Fabric

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description: Texturized glass fiber cloth is a soft, flexible cloth manufactured from continuous filament texturized yarns. It is an ideal replacement for asbestos product used for thermal insulation and heat protection. It has low coefficient of thermal expansion and is suitable for temperature up to 550℃

Features: Excellent insulation property, High working temperature 550℃, Tight yarn construction, High strength and abrasive

Application: Insulation blanket, Insulation jacket, Further processing

PRICE: USD2 per square meter

UNIT: square meter

MOQ: 500square meters

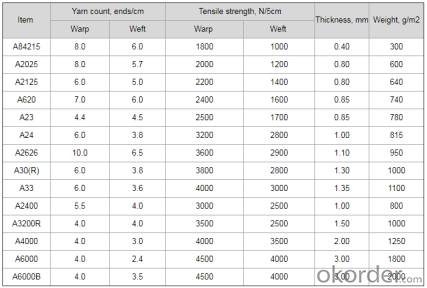

Weight: 300gsm-2000gsm

Thickness: 0.4mm-3mm

Roll length: customized

Size: can be customized

Supply ability: 300000 meters per month

Packaging: Rolls packed In cartons loaded on pallets or according to customers' requirements.

Lead time: 7-30 days

- Q:Is fiberglass fabric resistant to pests and insects?

- Yes, fiberglass fabric is generally resistant to pests and insects due to its synthetic composition and smooth surface, which makes it an unfavorable environment for them to thrive and cause damage.

- Q:Can fiberglass fabric be used for car covers?

- Yes, fiberglass fabric can be used for car covers. It is a durable and lightweight material that provides excellent protection against weather elements and UV rays. Additionally, fiberglass fabric is resistant to tearing and can withstand high temperatures, making it a suitable choice for car covers.

- Q:Is fiberglass fabric suitable for making tents and awnings?

- Yes, fiberglass fabric is suitable for making tents and awnings. It is lightweight, durable, and offers excellent resistance to extreme weather conditions such as rain, wind, and UV rays. Additionally, fiberglass fabric is known for its strong tensile strength and fire resistance, making it a reliable choice for outdoor applications.

- Q:Can fiberglass fabric be used for making awnings?

- Yes, fiberglass fabric can be used for making awnings. Fiberglass is a durable and lightweight material that is resistant to weather conditions, making it suitable for outdoor applications like awnings. It is also easy to clean and maintain, making it a popular choice for awning construction.

- Q:What are the environmental impacts of using fiberglass fabric?

- The utilization of fiberglass fabric can result in various environmental consequences. Initially, the extraction of raw materials, such as silica sand, for the production of fiberglass fabric can have detrimental effects on the environment. This extraction process can disturb local ecosystems, contribute to deforestation, and release harmful pollutants into the air and water. In addition, the fabrication of fiberglass fabric necessitates a significant amount of energy, often obtained from non-renewable sources. This energy consumption contributes to the emission of greenhouse gases, exacerbating climate change. Furthermore, the production process may also generate toxic byproducts, such as formaldehyde and volatile organic compounds, which, if not managed properly, can have adverse effects on human health and the environment. Another environmental concern associated with fiberglass fabric pertains to its disposal at the end of its life cycle. Fiberglass is not biodegradable and can persist in the environment for an extended period. Improper disposal, such as sending it to landfills, can lead to the release of microplastics into the soil and water, posing a threat to wildlife and ecosystems. Furthermore, fiberglass fabric is frequently coated with resins or chemicals to enhance its performance and durability. These coatings may contain harmful substances, such as heavy metals or flame retardants, which can leach into the environment during use or disposal, potentially contaminating soil, water, and air. In conclusion, the utilization of fiberglass fabric has wide-ranging environmental impacts, including habitat destruction, energy consumption, greenhouse gas emissions, the generation of toxic byproducts, inadequate end-of-life disposal, and contamination risks. It is crucial to consider these impacts and explore alternative materials or manufacturing processes that are more sustainable and environmentally friendly.

- Q:Is fiberglass fabric resistant to chemicals in swimming pools?

- Yes, fiberglass fabric is generally resistant to chemicals commonly found in swimming pools such as chlorine.

- Q:Can fiberglass fabric be used for insulation in data centers?

- Yes, fiberglass fabric can be used for insulation in data centers. Fiberglass fabric is known for its excellent thermal insulation properties, making it a suitable choice for insulating data centers. It helps in maintaining a stable temperature within the data center, preventing heat from escaping during cold weather and preventing excessive heat buildup during hot weather. Additionally, fiberglass fabric is also fire-resistant, which is crucial in data centers where the risk of fire can be high due to the presence of electrical equipment. Overall, fiberglass fabric provides effective insulation and contributes to the energy efficiency and safety of data centers.

- Q:What is the resolution of glass fiber cloth and polyester fiber cloth?

- It is mainly made of glass fiber and short needle non-woven fabric composite geosynthetics.

- Q:Waterproof method of glass fiber cloth for toilet

- Root canal sealant seal, cement smooth foot slip, waterproof paint brush when sticking glass cloth reinforced layer 1~2 layer. Similar measures near the floor drain.

- Q:How is fiberglass fabric woven?

- Fiberglass fabric is woven using a process known as plain weave or leno weave. In the plain weave method, the warp and weft yarns are interlaced at right angles, creating a simple crisscross pattern. This allows for a balanced and sturdy fabric structure. The leno weave technique, on the other hand, involves twisting adjacent warp yarns around each other in order to lock the weft yarns in place. This creates a more open and flexible fabric with increased stability. Both weaving methods are commonly used in the production of fiberglass fabric, depending on the desired characteristics and applications of the final product.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Temperature Thermal Insulation Texturized Fabric

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords