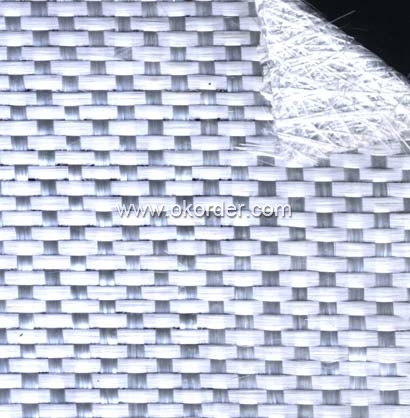

Fiberglass Stitch Combo Mat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- One Pallet kg

- Supply Capability:

- 20 days for 1 x 20FCL kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application of Fiberglass Stitch Combo Mat

Name: | E-Glass Stitch Combo Mats |

Lead Time: | 20 days for 1 x 20FCL |

MinOrder: | One Pallet |

Package: | Plastic Bag, Carton and Pallet |

Characteristic of Fiberglass Stitch Combo Mat

The special product construction where 0°,90°rovings are parallel aligned without crossing facilities resin impregnation in the layers of chopped strands, resulting in higher productivity and reduced consumption of resins.

The multi-layer structure delivers increased area weight and simplifies the manufacturing process of the composite products, resulting in improve molding productivity and reduced cost.

The composite products feature multi-directional and balanced mechanical properties.

Package of Fiberglass Stitch Combo Mat

Each stitch combo mat is wounded onto a paper tube which has an inside diameter of 73mm, and the roll has a diameter of 260mm. The roll is wrapped up with plastic film, and then packed in a cardboard box or wrapped up with kraft paper. The rolls are to be horizontally placed. For transporation the rolls can be loaded into a container directly or on pallets.

Storage of Fiberglass Stitch Combo Mat

Unless otherwise specified, fiberglass products should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃-35℃ and 35%-65% respectively.

Standard:ISO 9001

- Q:What are the different weaves available for fiberglass fabric?

- There are several different weaves available for fiberglass fabric, including plain weave, twill weave, satin weave, leno weave, and basket weave. Each weave has its own distinct characteristics and is chosen based on the specific requirements of the application.

- Q:Can fiberglass fabric be used for heat shields?

- Yes, fiberglass fabric can be used for heat shields. It has excellent thermal insulation properties and can withstand high temperatures, making it a suitable material for heat protection applications.

- Q:Can fiberglass fabric be used for reinforcement in construction materials?

- Yes, fiberglass fabric can be used for reinforcement in construction materials. It is a popular choice due to its high strength-to-weight ratio, durability, and resistance to corrosion. It is commonly used in applications such as reinforcing concrete, strengthening structural elements, and enhancing the overall performance and longevity of construction materials.

- Q:Can fiberglass fabric be used for reinforcement in wastewater treatment tanks?

- Yes, fiberglass fabric can be used for reinforcement in wastewater treatment tanks. Fiberglass fabric is known for its high strength-to-weight ratio, corrosion resistance, and durability, making it an ideal material for reinforcing structures exposed to harsh environments like wastewater treatment tanks. The fabric can be seamlessly applied to the tank surface, providing additional strength and structural integrity. Furthermore, fiberglass fabric is resistant to chemical attacks, which is crucial in wastewater treatment tanks where corrosive substances are often present. Overall, the use of fiberglass fabric for reinforcement in wastewater treatment tanks can significantly enhance the tank's lifespan and performance.

- Q:Can fiberglass fabric be used for making car seat covers?

- Yes, fiberglass fabric can be used for making car seat covers. Fiberglass fabric is known for its durability, strength, and resistance to heat, making it a suitable material for car seat covers. It is also lightweight and easy to work with, making it a popular choice for automotive applications. Additionally, fiberglass fabric is resistant to staining and can be easily cleaned, which is essential for car seat covers that are prone to spills and dirt. However, it is important to note that fiberglass fabric can be less comfortable compared to other materials, so additional padding or cushioning may be required to provide a comfortable seating experience.

- Q:What about laying glass fiber cloth on polyurethane waterproof coating?

- Polyurethane waterproof coating house strength is poor, mainly rely on glass fiber cloth this skeleton.

- Q:How is fiberglass fabric used in the production of protective gloves?

- Fiberglass fabric is used in the production of protective gloves as it provides excellent heat resistance and insulation properties. It is often used as a lining material in gloves to protect the wearer from extreme temperatures and potential burns. The fiberglass fabric acts as a barrier, preventing heat transfer and ensuring the safety of the user. Additionally, fiberglass fabric is lightweight and flexible, allowing for comfortable and dexterous glove designs.

- Q:Can fiberglass fabrics be used for automotive applications?

- Yes, fiberglass fabrics can be used for automotive applications. They are commonly used for making car body parts, such as hoods, fenders, and panels, as well as for reinforcing and strengthening various automotive components. Fiberglass fabrics offer excellent strength-to-weight ratio, durability, and resistance to corrosion and chemicals, making them suitable for automotive use.

- Q:Is fiberglass fabric easy to cut and sew?

- Yes, fiberglass fabric is relatively easy to cut and sew. Its thin and flexible nature allows for clean cuts and smooth sewing, making it manageable for various projects. However, it is important to take necessary precautions such as wearing appropriate protective gear and using sharp tools to ensure safety during cutting and sewing.

- Q:What is the lifespan of fiberglass fabric?

- The lifespan of fiberglass fabric can vary depending on factors such as its quality, usage, and maintenance. However, on average, fiberglass fabric can last anywhere from 10 to 30 years with proper care and handling.

1. Manufacturer Overview |

|

|---|---|

| Location | Zhejiang, China |

| Year Established | 1969 |

| Annual Output Value | Above US$ 150 Million |

| Main Markets | overseas companies in Hongkong, Canada, South Africa, South Korea, India, Italy, Singapore, France and many other countries and regions. |

| Company Certifications | ISO9001;ISO14001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 40%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English |

| b)Factory Information | |

| Factory Size: | Above 5000,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | |

| Product Price Range | Average |

Send your message to us

Fiberglass Stitch Combo Mat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- One Pallet kg

- Supply Capability:

- 20 days for 1 x 20FCL kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords