FIberglass RTM Mat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- One Pallet kg

- Supply Capability:

- 20 days for 1 x 40FCL kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of FIberglass RTM Mat

1.ISO9001-2008 quality control certificate.

2.Chopped Strand Mat for RTM

3.Good wet out in resins.

Have ISO9001:2008 quality control certificate.

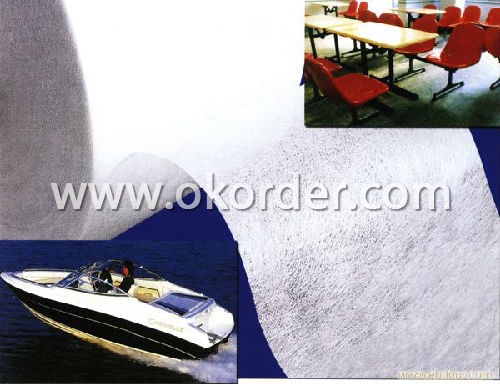

Chopped strand mat is suitable for application by hand lay-up, reinforce and machine FRPmolding, such as interior decoration of vehicles, boat hulls, sanitary ware, anticorrosive pipes, tanks, building materials, tables, chairs and all kinds of compisite FRP products.

Application of FIberglass RTM Mat

Product code | Glass type | Unite weight (g/m2) | Weight (mm) | Roll weight (kg) | Moisture (%) | Binder content (%) |

EMC100 | E Glass | 100+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 2-6 |

EMC150 | E Glass | 150+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 2-6 |

EMC200 | E Glass | 200+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 2-6 |

EMC300 | E Glass | 300+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 2-6 |

EMC450 | E Glass | 450+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 2-6 |

EMC600 | E Glass | 600+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 2-6 |

EMC900 | E Glass | 900+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 2-6 |

Packing of FIberglass RTM Mat

Product is manufactured in form of a roll wound on a paper tube and then packed in a plastic film and placed within craft on pallet.

Above package is standard one, any other package style is negotiable by both of us.

Storage of FIberglass RTM Mat

It is recommended that the fiber glass is stored in a cool and dry environment. Recommended temperature range of storage is between 10-30°C and relative humidity between 50-75%. The fiber glass should store in the packaging until just prior to use.

- Q:How is fiberglass fabric used in the fashion industry?

- Fiberglass fabric is not commonly used in the fashion industry. However, it can be occasionally utilized in avant-garde or experimental fashion designs for its unique properties such as durability, strength, and transparency. In such cases, it may be incorporated into clothing, accessories, or even as a structural element in runway shows.

- Q:How is fiberglass fabric used in the production of electrical cables?

- Fiberglass fabric is commonly used in the production of electrical cables due to its excellent insulation properties. The fabric is made from woven strands of glass fibers, which are known for their high electrical resistance. When used in electrical cables, fiberglass fabric acts as an insulating layer that helps protect the conductive wires from external factors such as moisture, heat, and physical damage. During the manufacturing process of electrical cables, the fiberglass fabric is often impregnated with a resin or polymer, which enhances its insulating properties and ensures its stability and durability. The impregnated fabric is then wrapped around the conductive wires, forming a protective layer that helps prevent electrical leakage and short circuits. Moreover, fiberglass fabric is highly resistant to fire, making it an ideal material for electrical cables. In case of a fire outbreak, the fabric acts as a barrier, preventing the flames from spreading along the cable and reducing the risk of further damage or accidents. In addition to insulation and fire resistance, fiberglass fabric also provides mechanical strength and flexibility to the electrical cables. Its woven structure enhances the cable's tensile strength, allowing it to withstand tension and bending without breaking or losing its functionality. Overall, the use of fiberglass fabric in the production of electrical cables ensures reliable and safe transmission of electrical currents while protecting the cables and the surrounding environment from potential hazards.

- Q:Are fiberglass fabrics suitable for use in the automotive industry?

- Yes, fiberglass fabrics are suitable for use in the automotive industry. Fiberglass fabrics offer several benefits that make them ideal for automotive applications. Firstly, fiberglass fabrics are known for their strength and durability. They have high tensile strength and are resistant to wear and tear, making them capable of withstanding the harsh conditions of the automotive environment. Fiberglass fabrics are also highly resistant to chemicals, moisture, and extreme temperatures, which further enhances their suitability for automotive use. Secondly, fiberglass fabrics are lightweight. This is a crucial characteristic for the automotive industry as it helps improve fuel efficiency and overall vehicle performance. By using fiberglass fabrics, manufacturers can reduce the weight of car components without compromising on strength and safety. Additionally, fiberglass fabrics have excellent thermal and electrical insulation properties. This makes them suitable for various applications in the automotive industry, such as insulation for engine compartments, exhaust systems, and electrical wiring. Furthermore, fiberglass fabrics can be molded into different shapes and sizes, allowing for customization and versatility in automotive design. They can be easily integrated into various components, including body panels, interior trims, and structural reinforcements. Overall, fiberglass fabrics offer a combination of strength, durability, lightweightness, insulation, and versatility, making them highly suitable for use in the automotive industry. They contribute to improved performance, fuel efficiency, and safety in vehicles, making them a popular choice among automotive manufacturers.

- Q:How is fiberglass fabric used in the production of insulation blankets?

- Fiberglass fabric is commonly used in the production of insulation blankets due to its excellent thermal resistance and insulating properties. It is a lightweight material made from fine fibers of glass, which are woven together to create a fabric. This fabric is then used as a layer in insulation blankets. Insulation blankets are designed to reduce heat transfer and maintain temperature control in various applications. They are commonly used in industries such as aerospace, automotive, and construction. The fiberglass fabric used in these blankets acts as a barrier, minimizing the conduction of heat. The fiberglass fabric used in insulation blankets is typically coated with a fire-resistant material, such as silicone or aluminum, to enhance its performance and durability. This coating helps to prevent the spread of flames in case of a fire, making the insulation blankets safer to use. The fiberglass fabric is also resistant to moisture, chemicals, and UV radiation, making it suitable for different environments and applications. It is a flexible material that can be easily customized and cut to fit specific shapes or sizes, allowing for easy installation in various equipment and structures. Moreover, fiberglass fabric is known for its high tensile strength, which ensures the longevity and reliability of insulation blankets. It can withstand high temperatures and maintain its structural integrity, making it an ideal choice for insulation purposes. In summary, fiberglass fabric is used in the production of insulation blankets due to its thermal resistance, insulating properties, fire resistance, moisture resistance, chemical resistance, UV resistance, flexibility, and strength. Its usage helps to improve energy efficiency, maintain temperature control, and enhance safety in a wide range of industries and applications.

- Q:Can fiberglass fabric be used for insulation in breweries?

- Indeed, fiberglass fabric proves to be a viable option when it comes to insulating breweries. Renowned for its exceptional insulation capabilities, this material boasts a low thermal conductivity and a remarkable resistance to heat transfer. Consequently, it stands as an ideal choice for a range of insulation needs within breweries. The significance of insulation in brewery settings cannot be overstated, as it serves to uphold specific temperature requirements for various brewing processes such as fermentation, mashing, and boiling. By utilizing fiberglass fabric, one can effectively insulate brewing vessels, pipes, and tanks. This guarantees the retention of heat or the prevention of its entry, depending on the specific demand. Moreover, fiberglass fabric possesses a notable resistance to moisture, a vital feature in brewery environments characterized by elevated humidity levels or exposure to liquids. Its non-absorbent nature ensures that its insulation capabilities remain uncompromised over time. Notably, fiberglass fabric proves to be easily installable and customizable to fit a range of sizes and shapes. This versatility makes it an advantageous choice for brewery insulation. Its lightweight and flexible nature facilitate effortless handling and installation across various areas within the brewery. All things considered, the excellent thermal insulation properties, moisture resistance, and ease of installation make fiberglass fabric a highly suitable option for brewery insulation. By employing this material, one can maintain optimal temperature conditions, enhance energy efficiency, and ensure the quality of the brewing process.

- Q:What material can be used instead of fiberglass cloth?

- Glass fiber cloth has many kinds of specifications and thickness, can be purchased as needed, non-woven fabrics without glass fiber fabric, strong, and generally can not be replaced.

- Q:Can fiberglass fabric be used for making aircraft parts?

- Yes, fiberglass fabric can be used for making aircraft parts. It is often used in the construction of lightweight and durable components such as fairings, radomes, and interior panels. Fiberglass fabric offers excellent strength-to-weight ratio and is resistant to corrosion, making it a suitable material for aviation applications.

- Q:Can fiberglass fabrics be used for automotive applications?

- Certainly, automotive applications can indeed make use of fiberglass fabrics. Fiberglass fabrics possess notable characteristics such as high strength-to-weight ratio, durability, and resistance to heat and chemicals. These qualities render them appropriate for a variety of automotive uses like reinforcing body panels, constructing interior components, and creating structural reinforcements. By molding and shaping fiberglass fabrics, specific automotive parts can be easily accommodated, providing both strength and stability while simultaneously reducing weight. Moreover, the thermal insulation properties of fiberglass fabrics make them highly suitable for employment in automotive exhaust systems and engine compartments. All in all, fiberglass fabrics bring forth numerous advantages in terms of performance, durability, and design flexibility, thus proving their suitability for a wide array of automotive applications.

- Q:Sofa three proofing fabric and 6 anti distinction

- Three proof cloth is PVC coated glass fiber cloth. Three cloth is coated on the surface of PVC, PTFE refractory fiber, flame retardant silicone and other refractory materials, make fire waterproof mildew proof function, refractory fiber with fire, PVC, PTFE, silica gel has a waterproof function.

- Q:Is fiberglass fabric suitable for use in architectural applications?

- Architectural applications can benefit greatly from the use of fiberglass fabric. This versatile material offers a multitude of advantages. Its high tensile strength and durability make it a great choice for reinforcing concrete structures, creating lightweight panels and cladding systems, and providing insulation. Architects and designers can take advantage of fiberglass fabric's ability to be molded into various shapes and sizes, allowing them to create unique and creative structures. It is also resistant to corrosion, chemicals, and moisture, making it suitable for both interior and exterior applications. Fire safety and energy efficiency are important considerations in architectural projects, and fiberglass fabric ticks both boxes. It is fire-resistant and has excellent thermal insulation properties, making it an ideal choice for these applications. In addition to its practical benefits, fiberglass fabric is also lightweight, making it easier to handle and install compared to materials like steel or concrete. Its flexibility allows it to be draped or wrapped around complex architectural features. Architects can also achieve their desired aesthetic appearance for their projects with fiberglass fabric, as it is available in a wide range of colors and finishes. However, it's important to note that proper maintenance and periodic inspections are necessary to ensure the long-term performance of fiberglass fabric. Following the installation techniques and guidelines provided by manufacturers is essential to ensure its suitability and effectiveness in architectural applications. In conclusion, fiberglass fabric is a suitable material for architectural applications due to its strength, durability, versatility, fire resistance, thermal insulation properties, and aesthetic options. However, it's crucial to consider specific project requirements and consult with experts to determine the most appropriate use of fiberglass fabric in each architectural application.

1. Manufacturer Overview |

|

|---|---|

| Location | Zhejiang, China |

| Year Established | 1969 |

| Annual Output Value | Above US$ 150 Million |

| Main Markets | overseas companies in Hongkong, Canada, South Africa, South Korea, India, Italy, Singapore, France and many other countries and regions. |

| Company Certifications | ISO9001;ISO14001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 40%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English |

| b)Factory Information | |

| Factory Size: | Above 5000,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | |

| Product Price Range | Average |

Send your message to us

FIberglass RTM Mat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- One Pallet kg

- Supply Capability:

- 20 days for 1 x 40FCL kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords