FRP Pultrusion Roof Tile Sheets or Panels

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500M2 m²

- Supply Capability:

- 900M2/Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

FRP Pultrusion Roof Tile Sheets or Panels

Description

In general, our company specializes in FRP grating, FRP decking, FRP platform and other products of FRP. We have a varity of FRP products sold over the country because we have our own teams of design, manufacturing and sales with hundreds of staffs.

At the same time, we are devoted to creating a production and marketing for FRP products, which has certain influence in China by proceeding with professional teams, rigorous quality management system and advanced production facility.

Today, we’re planning to win more market shares in the world and let more customers know us.

Photos

Product Traits

1. Corrosion resistance no rust, no maintenance, long service life.

2. Lightweight, high strength pultrusion process molding FRP profiles have high glass fiber content (60%). In this situation, the density of glass fiber reinforced plastic is only about a quarter of the steel.

3. The intensity and stiffness is quite prominent,.

4. Anti-fatigue high anti- fatigue strength, allowing repeated bending without permanent deformation.

5. Anti-aging select highquality FRP pultrusion profiles, the service life of the product can be more than 20 years.

6. Anti-UV agent are added into all pultrusion FRP profiles get the best anti-uv effect.

Product Advantage

Coated with prevent aging layer

Excellent insulating performance

Easy to maintain.

High strength.

Long service life.

Easy to install.

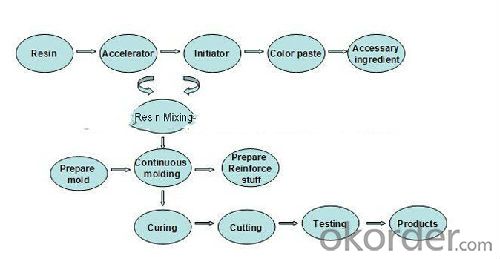

Production Process

Specification

Mechanical properties: high rigidity lighting panels

Plate matches: match with general prepainted galvanized sheet, galvanized steel

Resin composites: Improved anti-aging SMR198 resin

Fiber reinforcement: E-glass fiber untwisted without glue

Surface treatment: affixing MELINEX301 film

Stiffener line: surface with longitudinal uniform distribution of anti-LAC gluten

Glass fiber: not less than 28%

Unit Weight: 1800g / ㎡, 2400g / ㎡, 3050g / ㎡

Nominal thickness: 1.2 mm, 1.5mm, 2.0mm (tolerance ≤ 10%)

Temperature limits: -60 ℃ ~ +130 ℃

Transmittance (1.5mm): 72% ± 2% (fog white, sky blue, water green), 52% ± 2% (white porcelain)

UV-rate: 99%

Tensile strength: 90Mpa

Flexural strength: 160 Mpa

Elongation: 1.9%

Pap hardness: ≥ 50

Thermal expansion coefficient: 1.5 ~ 3.2 * 10-5 / K

Thermal conductivity: K = 0.23W / m * K

Guarantee: 15 years

NOTE: In special cases, the surface film varieties vary according to needs, such as Melinex389, PT055 and so on

FAQ

1.Which country do you mainly export to?

A: Our products are very popular in Mid East, India, South East Asia, Latin America, Africa.

2.Q: What’s the advantage of you compared with other suppliers experienced in foreign trade?

A: We have been specialized in FRP products for over decades years and approved by many domestic companies. Except for our quality and price, we’re also able to give you the best service.

3.Q:Can you provide some samples?

A: Yes, of course. We will send you samples for your confirmation before you place firm orders.

- Q:How do fiberglass fabrics perform in terms of thermal conductivity?

- Fiberglass fabrics have low thermal conductivity, meaning they are poor conductors of heat. This property allows them to insulate and retain heat effectively, making them suitable for applications where thermal insulation is required.

- Q:Can fiberglass fabric be used for insulation in oil and gas facilities?

- Yes, fiberglass fabric can be used for insulation in oil and gas facilities. Fiberglass fabric is a commonly used material for insulation due to its excellent thermal properties, resistance to high temperatures, and its ability to withstand harsh environments. It is non-combustible and can effectively prevent heat transfer, making it suitable for insulating pipes, tanks, and equipment in oil and gas facilities. Additionally, fiberglass fabric is lightweight, flexible, and easy to install, making it a practical choice for insulation in these facilities.

- Q:Are fiberglass fabrics easy to sew or work with?

- Sewing or working with fiberglass fabrics is typically not an easy task due to their unique properties and characteristics. Unlike other textiles, fiberglass fabrics are incredibly durable and resistant to heat, fire, chemicals, and most environmental factors. These qualities make them perfect for insulation, protective clothing, and adding strength to composites. However, these same properties also make them challenging to sew or work with. The primary difficulty in sewing fiberglass fabrics lies in their stiffness and rigidity. Unlike conventional fabrics, fiberglass fabrics lack flexibility, which makes them challenging to handle and manipulate. Their inability to stretch also makes it difficult to shape or contour them to fit certain designs. This can create complications when attempting to sew complex or intricate patterns using fiberglass fabrics. Furthermore, the sharp and abrasive nature of fiberglass fibers can cause damage to traditional sewing machines, needles, and threads. The sharp edges of the fibers can quickly wear down needles and lead to thread breakage or fraying. This can result in frustration and inefficiency when working with fiberglass fabrics. To overcome these challenges, specialized techniques and equipment are often necessary when sewing or working with fiberglass fabrics. This may involve the use of heavy-duty sewing machines, specialized needles and threads, and taking precautions to protect oneself from potential health hazards associated with fiberglass fibers. In conclusion, although fiberglass fabrics offer excellent performance and durability in various applications, they are not as easy to sew or work with compared to traditional textiles. The stiffness, lack of flexibility, and abrasive nature of the fibers require the use of specialized techniques and equipment to successfully work with these fabrics.

- Q:Are fiberglass fabrics resistant to static electricity?

- Yes, fiberglass fabrics are generally resistant to static electricity. This is because fiberglass is a non-conductive material, meaning it does not allow the flow of electrical current. Static electricity is generated when two materials with different electrical charges come into contact and then separate, causing an imbalance of electrons. As fiberglass is a non-conductive material, it does not easily build up or hold static charge. This makes fiberglass fabrics less likely to generate or hold static electricity compared to materials that are conductive or have a higher level of electrical conductivity. However, it's important to note that the specific properties of the fiberglass fabric can vary depending on its composition and any additional treatments or coatings it may have.

- Q:Can fiberglass fabric be used for insulation sleeves?

- Indeed, insulation sleeves can be created using fiberglass fabric. Fiberglass, a material commonly utilized for insulation purposes, possesses exceptional fire resistance properties and boasts high thermal resistance. Its ability to withstand elevated temperatures, combined with its capability of being woven into fabric form, renders it suitable for the production of insulation sleeves. These sleeves serve the purpose of safeguarding and insulating various components such as pipes, wires, and cables, shielding them from both heat and cold. By acting as a barrier, the fiberglass fabric effectively hampers heat transfer and provides insulation to the enclosed area. Additionally, fiberglass fabric boasts the advantages of being lightweight, flexible, and durable, thereby ensuring ease of use and long-lasting performance in insulation applications.

- Q:Can fiberglass fabric be used for making insulation blankets?

- Indeed, insulation blankets can be manufactured using fiberglass fabric. Renowned for its remarkable thermal insulation qualities, fiberglass fabric proves to be a perfect material for crafting insulation blankets. These blankets are specifically engineered to confine heat and hinder its transmission, ensuring efficient insulation across diverse contexts like residential abodes, industrial environments, as well as aerospace and automotive sectors. Typically, the fiberglass fabric employed in insulation blankets is woven or knitted, rendering it supple and effortlessly modifiable to suit various shapes and dimensions. Moreover, fiberglass fabric exhibits traits of being lightweight, fireproof, and resistant to both chemicals and moisture, thereby establishing itself as a dependable option for insulation purposes.

- Q:Can fiberglass fabric be used for reinforcement in underground storage tanks?

- Yes, fiberglass fabric can be used for reinforcement in underground storage tanks. Its high strength, corrosion resistance, and durability make it a suitable material for reinforcing the structure of underground storage tanks, ensuring their structural integrity and preventing leaks or failures.

- Q:Are fiberglass fabrics suitable for use in the renewable energy sector?

- Yes, fiberglass fabrics are suitable for use in the renewable energy sector. Fiberglass fabrics are known for their high strength and durability, making them ideal for various applications in renewable energy. One of the key uses of fiberglass fabrics in the renewable energy sector is in the manufacturing of wind turbine blades. Fiberglass fabrics are used to reinforce the blades, providing them with the necessary strength to withstand high winds and turbulent conditions. The lightweight nature of fiberglass also allows for longer blades, resulting in increased energy output. Additionally, fiberglass fabrics are used in the production of solar panels. They are often used as a protective layer to encapsulate the photovoltaic cells and provide insulation. Fiberglass fabrics offer excellent electrical insulation properties, ensuring the longevity and efficiency of solar panels. Moreover, fiberglass fabrics are used in the construction of thermal insulation materials for solar water heaters and geothermal systems. These fabrics help to retain heat, thereby increasing the efficiency of these renewable energy systems. Furthermore, fiberglass fabrics are resistant to corrosion and have a long lifespan, making them suitable for use in marine renewable energy projects such as wave energy converters and tidal turbines. These fabrics can withstand the harsh marine environment and provide structural support to these devices. In conclusion, fiberglass fabrics have numerous applications in the renewable energy sector. Their strength, durability, electrical insulation properties, and resistance to corrosion make them an excellent choice for various renewable energy technologies, including wind turbines, solar panels, thermal insulation materials, and marine energy devices.

- Q:What are the different thicknesses of fiberglass fabric used in insulation?

- The different thicknesses of fiberglass fabric used in insulation can vary depending on the specific application and desired level of insulation. However, common thicknesses range from 0.5 inches to 2 inches.

- Q:Glass fiber cloth can be made into handbags, requirements of high temperature 680 degrees or more

- We try to do is pack, but now not sure whether the temperature has been reached, but the manufacturer is reply to the temperature, fastness is poor, (in order to increase the strength, and the waterproof, we added composite cloth, so the bag looks very thick), the other looks good, as long as the fastness to strengthen, meet standard

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FRP Pultrusion Roof Tile Sheets or Panels

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500M2 m²

- Supply Capability:

- 900M2/Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords