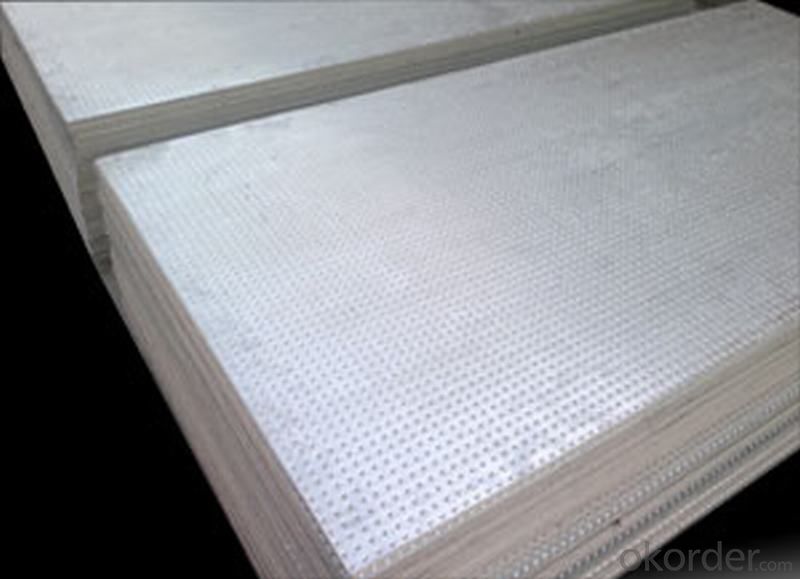

Fiber Cement Boards Fiber Cement Board For Floor

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The raw materials of fiber cement board are cellulose fiber, silicate cement, quartz sand, water and some additives. It's a kind of high-tech product which formed through accurate dosing by computer program, hatschek craft and compressed by 14000tons hydraulic machine and autoclaved under high temperature and pressure.

Product Applications:

Fiber cement board can be used in exterior wall cladding and facade of various high-class and high rise civil buildings especially in the modern luxurious buildings. Outstanding sound insulation of the system composed with Bysink external wall board can be used in indoor partition and suspended ceiling for the high demand in private request as sound insulation and such as five star hotel, bedroom, and public entertainment.

Also it can be used as the interior partition in the shops, hotels, schools, entertainment places and hospitals.

Product Advantages:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

5)stable dimensions

6)good heat and sound insulation

7)non-asbestos

8)mould resistant

9)no deformation

Main Product Features:

1) Elegance and excellent decoration

2) Easy installation and convenient maintenance

3) Best Surface processed with PVC Lamination

4) Heat insulation, thermal insulation, moisture proof, mould proof, sound absorption and noise reduction

5) Incombustibility / Fireproof

6) No dust / no pollution

7) Stucturally strong

8) Over 15 years no transmutation

Product Specifications:

FAQ:

1. Q:What is the different and most important point from other supplier?

A:We guarantee No asbestos if it has asbestos density will be more than 1.4g/cm3 what's more

3.2mm*3000*1220mm can be produced by us other suppliers can not do this size

2. Q:What are the advantages of your board?

A: outstanding light weight ,heat insulation, waterproof, fireproof, sound insulation, fast construction.

3. Q: Is the board fire resistant?

A: Yes, fire resistant 4 h , in the heat of 1000℃.actually it is noncombustible Class A1.

4. Q: Do you have any certificate to help us get government's approval?

A:China testing report and our laboratory' s testing by ourselves as your supporting document.

Because building standards are different in different countries, most of our customers buy the boards for testing and get approval by themselves.

5. Q: If we need samples for customer approval, will it be possible?

A: Of course we can.

6. Q:How to guarantee the quality?

A:Laboratory, integral testing process from raw materials to finished product until loading containers will be done by our factory.

Images:

- Q:How much is the cement board?

- Cement board raw materials generally do not sell according to the square Zhang, each 1220MM * 2440MM gypsum board than some of your 20-25 look.

- Q:more upscale. is this true? is there a big difference in the look? how do they differ in appearance? whats so great about it?

- both of the above are true, vinyl is maintenance free but can look cheap, fake, and plastic. fiber cement is more expensive but looks rich, like real wood, and is virtually indestructible

- Q:Can I lay tile on top of an old cultured marble top w/o cement board or plywood?

- no.... you have to have some type of underlyment..... or it will come out like crap....

- Q:how do you join cement board from a shower wall to drywall?

- Other than being nailed to the same stud, it is not all that necessary that they be joined together. Just figure on the tile overlapping the drywall about a half an inch to kill the crack. You can mesh tape them together however and skim them flat with each other as long as you don't skim wide into the tile board area. You could do as little as just caulk the crack with silicone too.

- Q:Where is the cement pressure plate installed?

- Light keel plus cement pressure plate: Formal method: only use three light keel plus two pieces of cement pressure plate production. Light Gang keel did not make the frame, but played a connection role. This is not strong enough. But the provincial workers expected material. Formal methods: the use of light keel made of frames, after the supervision and acceptance by the Party, and then sealed cement pressure plate, linked to steel wire mesh, and finally paste the disk. Features: not easy to deformation, nowadays the most commonly used company decoration process. Plastic buckle plate, plastic aluminum plate production: These two methods for home decoration finished, and want to wrap up the riser. Because it is not necessary to fill the disk, it is convenient. Plastic buckle: wood keel plus angle, directly from the bottom of the buckle up into the installation. Disadvantages: not beautiful. Aluminum-plastic plate: wood keel on the nail nine PCT board, and then all the glue to the aluminum-plastic plate stick to a variety of colors, close to the disk effect. Disadvantages: aluminum-plastic plate angle is easy to crack, should use thicker plate.

- Q:911 polyurethane brush in the cement board is what is the bubble

- Wood paint after brushing the phenomenon of blistering, often before brushing, can not be mixed with wood paint and then no longer let it rest for half an hour or so again and again the phenomenon of operation. In addition, in the brushing because of the window and make the wind blowing in the decorative panels, but also cause the phenomenon of blistering. This phenomenon is more trouble, with fine sandpaper to the bubble at the light of the sand level, and then dry with a dry cloth, and then make up the same wood paint. Sometimes fill the paint at the larger color, it must also be the whole face all brush again.

- Q:We are remodeling our Bath and have put cement board around the shower which we will tile. My question is, do I continue to use cement board around the remainder of the bath or put up green board. The cement board in only 1/4 inch. Can I get greenboard that is 1/4 in. thick? I don't want a ridge between were the two meet. The tile will run half way up the wall and the other half painted in the remaining part of the bath.

- if the cement board is 1/4 inch think then add 1/4 inch backer board under the cement board to bring out the finished wall to 1/2 inch....all wall should be 1/2 or better.... walls that have 1/4 drywall are not stronge enough and will sag...

- Q:in my new bath/shower i'm using hardibacker cement board. what should i use for the rest of the bathroom walls

- Keep the two bath/ shower walls the same, the other two or more walls you can use WR board (water resistant gyprock) witch you can get from any plaster board shop or bunnings. Good luck!

- Q:We are using quality 3/4 plywood as the base - can we glue the tiles directly to this wood or does there need to be something between the wood and the glue/mortar?

- You can use two layers of 3/4 going cross grain to the bottom but there still is the possibility that the wood will swell and move if you don t glue and screw it together well. Its better to use a 1/2 cement board. And still use thin set between the 2 layers and nail ( galvanized roofing nails) or screw it well. Any questions you can e mail me through my avatar and check my qualifications there. GL

- Q:My husband fixed the faucet in the tub around two years ago. He cracked one of the tiles. We bandaged the area, but water has been getting behind the tiles. So, we have water damage. Plus, there is this weird white fungus looking stuff that is growing in some of the grout lines. I don't want to just put a liner over this mess. I would like to pull all the tile off and put cement board up (the house is old and it has sheet rock behind the tile), so i can start fresh. Will the liner hold up the same if it is glued to cement board rather than tile?

- I'd remove the tile, the fungus could be mold or mildew and you don't want to trap or seal that in the walls. I the wall board behind is moldy or in bad shape, replace that too with greenboard (water/mildew resistant backerboard)

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiber Cement Boards Fiber Cement Board For Floor

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords