High Density Fiber Cement Board Prices for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

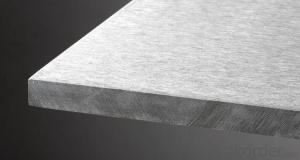

High Density and Strength fiber cement board is a high quality calcium silicate architectural board reinforced with selected cellulose fibres and fillers.

The raw materials of fiber cement board are cellulose fiber, silicate cement, quartz sand, water and some additives.

It is 100% free from asbestos, sepiolite, inorganic fibres or formaldehyde.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

Product Advantages:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

Main Product Features:

1) Elegance and excellent decoration

2) Easy installation and convenient maintenance

3) Best Surface processed with PVC Lamination

4) Heat insulation, thermal insulation, moisture proof, mould proof, sound absorption and noise reduction

5) Incombustibility / Fireproof

6) No dust / no pollution

Product Specifications:

FAQ:

1. Q:What is the different and most important point from other supplier?

A:We guarantee No asbestos if it has asbestos density will be more than 1.4g/cm3 what's more

3.2mm*3000*1220mm can be produced by us other suppliers can not do this size

2. Q:What are the advantages of your board?

A: outstanding light weight ,heat insulation, waterproof, fireproof, sound insulation, fast construction.

3. Q: Is the board fire resistant?

A: Yes, fire resistant 4 h , in the heat of 1000℃.actually it is noncombustible Class A1.

4. Q: Do you have any certificate to help us get government's approval?

A:China testing report and our laboratory' s testing by ourselves as your supporting document.

Because building standards are different in different countries, most of our customers buy the boards for testing and get approval by themselves.

Images:

- Q:Can you put tile directly on top of green board in a shower or do you have to also use cement board?

- Yes you can. Cement board has not been around all that long, and people used to tile over green board. Now that cement board is available at every building supply in the world, there is no reason to use green board. All it is , is a moisture resistant blue board. If water gets through your grout lines, you end up with a sponge in your wall. The only place I might use it, is on the ceiling of a shower stall.

- Q:Do not you dry the stone

- Cement fiberboard, also known as fiber cement board. Is based on siliceous, calcium material as the main raw material, adding plant fiber, after the pulp, copy, pressure, conservation made of a new type of building materials. After the high-pressure production of cement fiber board, also known as fiber cement pressure plate, its performance is better than the non-pressurized cement fiber board.

- Q:I've already got the cement board down, taking it back up would mean messing with the toilet flange, which means plumbing, and that sucks. Plywood was in pretty good condition. Thanks in advance!

- Ya, you should make sure that you have enough screws in it so it doesnt shift. thats the main purpose of thinset between the cementboard and subfloor. If your using hardibacker it shows you were every screw should go about 25 screws in each. You also should thinset the joints, just like drywall.

- Q:our cement board was left out in a rain storm and then was installed under marble tiles. will this be an issue?

- Yes it can, but makes sure its dry before it gets closed off (tiled over)

- Q:Package toilet water pipes, do not want to use red brick (too heavy), want to use lightweight materials, but also want to paste the tiles. Can you elaborate?

- You can use glass fiber cement board bag toilet water pipe, lightweight, durable, above can be tiled, you ask to do waterproof decoration master, they all understand

- Q:I've done the hard way - bunches of expensive special screws. I found that to be expensive and time consuming (and therefore back breaking). It seems like it takes just as long to do the backer board as it does to do all the remaining steps with the tile. Can I use nails? If so, what kind? Thinset and nails? The subfloor is plywood with old vinyl tiles, I have no intention of remove the old vinyl tiles first. Please reply if you have personal experience with an alternative. Thanks!

- There are a few factors that need to be considered. What is your subfloor? If its concrete and the vinyl is secured very well, then you can lay over it provided you put an acrylic additive in your thinset. This will help the bond to the vinyl. Also by doing this the vinyl will act as a crack supressant to the tile and protect against any cracks from your subfloor moving up to the tile. If you have a wood subfloor, you should remove the vinyl, install a 1/4 backerboard(not 1/2) and then install the tile with a modified thinset.

- Q:I removed old tile from my bathroom walls as well as the old vinyl flooring. Underneath the vinyl was cement backerboard, which is good. But all around the outer edges where the wall tile used to be, is a 1 inch gap where the floor board are showing. How do I get this gap filled? Do I need to rip up the old cement backerboard and start over? Can I cut small strips of new backerboard to slip in the crevice? Is there a compound I can fill the gap with? Any help out there?

- If you have the backer board yes you can rip it and put it in. If you do not you can use some of the thinset you (should use) are going to put the tiles down with. Just mix it a little more dry than it calls for (not too dry) and fill this area in and let it dry for a day. Then go back and tile away. The only reason I am not telling you to go out and buy another product is that if it is along the wall edges and it is only an inch its a waste of time and money, you will be fine.

- Q:I'm making designs for a house I want to build. Initially I wanted to build the house out of primarily concrete, however because of where the house is going to be going, it's not really plausible to get that amount of concrete out there to pour at once (it would be extremely difficult to get a truck out there).So my next consideration would be to build an otherwise traditional frame and instead of using drywall on the inside, I would use cement boards to panel the walls, and go for a clean, future-industrial look. I was also intending on doing something similar to the exterior.However, cement boards obviously weigh significantly more than typical drywall panels, and my main concern is whether or not a regular wood frame would be able to hold that amount of weight. So would that pose a significant issue to the extent that I should also consider using steel for the entire frame, or at least as a support system, or should wood be able to hold up just fine?

- Cement Board Drywall

- Q:I'm ready to tile my kitchen soon. My husband and I have torn up the carpet and 2 layers of linoleum, leaving only some leftover glue from the linoleum and the wood sub floor. Do we really need to lay cement board over the wood sub floor or can we just go ahead and tile right on the wood? (FYI: it will be either ceramic or porcelain tile)

- I take you're in in the USA so not sure you can get an elastomeric adhesive such as BAL fast flex. If your sub floor is sound and deflection free you could use this.

- Q:Is it possible to use a cement board with a small double intermediate compartment?

- Yes, the first board for the two-way board, plate thickness for the short span of 1/40 ~ 50, you can use 90 ~ 112.5mm thick

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Density Fiber Cement Board Prices for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords