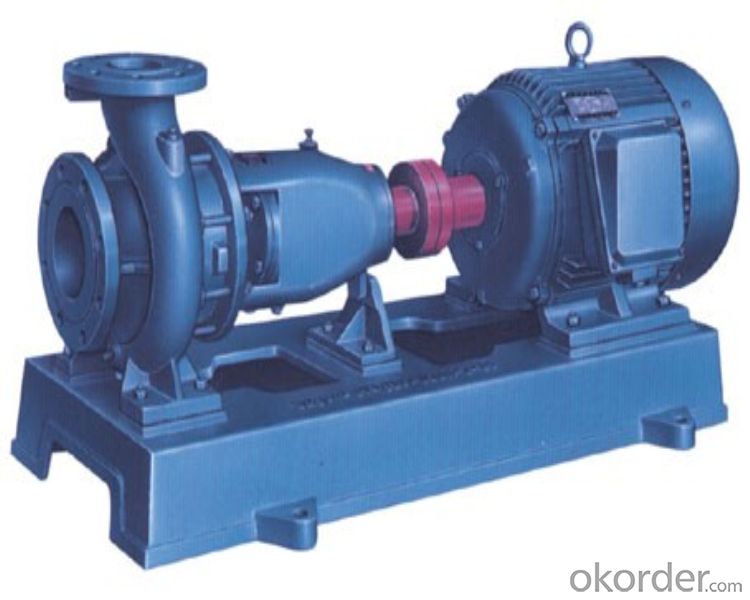

Stain Steel Centrifugal Pump Impeller China Made

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Stain Steel Centrifugal Pump Impeller China Made

Company Introduce

My company has more than 40 years history, is the China general machinery pump industry association member units.

The company has organized product research and development team, experienced high, intermediate technical staff.Complete production and processing, inspection, testing (pump performance test platform), and other equipment, to ensure that product quality is stable and reliable.Over the department, provincial, municipal and industry product quality supervision and inspection (smoke), only one is qualified to go through.Timely quality perfect after-sales service in place, favored by the majority of new and old customers rely on and praise.

The company has successfully passed the national industrial products production license, ISO9001 quality system review replacement work.Relevant product standards (enterprise), metrology, standardization management system, etc., have been acceptance by the superior department in charge of the inspection.Related to product development, production management, sales and after-sales service, are performed according to the system management standard.

Product Parameters of Stain Steel Centrifugal Pump Impeller China Made

| Capacity: | 6.3~400m³/h |

| Head: | 5~125m |

| Speed: | 2900r/min and 1450r/min |

| Power of fitted motor: | 0.55~90kW |

| Inler diameter: | 50~200mm |

| The max working pressure: | 1.6MPa |

Application Range of Stain Steel Centrifugal Pump Impeller China Made

1.Suitable for environment protection, construction, fire fighting, chemical pharmacy, printing, dyeing, brewage, power plant, electroplate,

paper making, washing for mining and cooling for equipment.

2.Application as sprayer equipped with beam nozzle that turning water into little drop irrigation for farm, garden, etc.

3.It is suitable for clear water, sea water, acid or alkali chemical medium and slurry (viscosity≤100 centipoise, consistency of solid can not exceed 30% of total medium).

Stain Steel Centrifugal Pump Impeller China Made Features

1. Resistant to acid, alkali, wear and high temperature.

2. High mechanical strength, steady performance, good tightness.

3. Convenient operation and durable.

4. Be able to transport water that under the position it was installed. No need for filling liquid after the first time it was used.

Stain Steel Centrifugal Pump Impeller China Made Superiority

High efficiency

Reasonable design

Reliable operation

Long in service time

Easy maintenance

Low running cost

Pictures show

Why choose us

High Quality

1.Exported to 58 Countries

2. More than 90% customers make payment before meeting us!

3. Reorder rate up to 80%

4. Never sell any renewed pumps

5. Focus on middle and high-end market,we never seize market by using inferior material

FAQ

1. How to get our quotation in time, pls answer following questions:

1)What liquid do you transfer?oil ,food or corrosive chemical liquid,with solid particle or not and so on

2) What's the flow or capcity (m3/h, L/m)?

3) What's the discharge head (m, feet, Mpa, bar )

If you do not have any request, we will do as our normal standard.

4) Contact us by under business card information

2.OEM: Ok

3. MOQ: 1set

4. Package: Standard export wooden case(also according to your requirements)

5. Shipping ways: By sea, By air, By express

6. Lead time: 3-15days

7. Warranty Period: One year, except spare parts

Trading market

After-sales service

Transportation

Related products

|

|

Fire Pump Cast Steel High Speed China Made | Cast Steel Centrifugal Pump High Pressure |

| http://www.okorder.com/p/fire-pump-cast-steel-high-speed-china-made_976663.html | http://www.okorder.com/p/cast-steel-centrifugal-pump-high-pressure_975173.html |

- Q:How do you remove it without taking the engine out?

- Disconnect lower radiator hose (8286) from the water pump lower tube. Remove the engine mount nuts. Remove the cowl extension panel. Disconnect the water bypass hose and the heater hose from the water pump outlet tube. Remove the water pump outlet tube bolt and position the tube assembly out of the way. Install the lifting eye to the exhaust manifold (9430). Attach engine lifting equipment and raise the engine 127 mm (5 inches). Remove the bolt and the accessory belt idler pulley. Remove the bolts and the generator support bracket. Remove the four bolts and the water pump pulley (8509). Remove the water pump. Remove the five nuts. Remove the five studs. Remove the four bolts. Remove the water pump, lower tube and gasket as an assembly.

- Q:I have a leak and all the hoses are fine but I am not sure were the water pump is also has anyone had this repaired and what did it cost (part plus labor) in general is it hard to get to? Thanks in advance

- 1995 Chrysler Concorde Parts

- Q:my water pump is leaking and chirping would like to know the procedure

- Disconnect battery ground cable. Drain coolant from radiator. Remove upper fan shroud. Remove drive belt. Remove fan assembly from engine. Lower radiator and heater hose from the water pump. Remove water pump attaching bolts and water pump, Fig. 15 . Reverse procedure to install. Tighten water pump attaching bolts to specifications

- Q:Pump performance parameters have three sets of data, how to understand the flow, lift, flow speed

- 1, the head is composed of a water pump design decisions, such as motor speed, power, blade shape; the flow is determined by the motor power and lift, the same power lift higher flux is small; velocity determined by flow and pipe section with a pump pipeline section greater velocity.2, the pump is to transport liquid or liquid pressurization machinery. It will be the prime mover of the mechanical energy or other external energy transfer to the liquid, the liquid energy increase, mainly used to transport liquids including water, oil, alkali liquid, emulsion, suspension emulsion and liquid metal, but also transport liquid, gas mixtures and liquids containing suspended solids. Pump performance of technical parameters are flow, suction, lift, shaft power, water power, efficiency, etc.; according to the different principles of work can be divided into volume pumps, vane pumps and other types. Displacement pump is to use its studio volume changes to transfer energy; vane pump is to use the rotating blade and water interaction to transfer energy, there are centrifugal pumps, axial flow pumps and mixed flow pumps and other types.

- Q:Which professional friends ask, I encountered a problem in the design of fire pump head 90 meters, flow rate is 20/S, power is 37KW, but the construction side to buy the pump head and flow are achieved, but the power is only 30KW, this relationship? If you can, let me know by the way, thank you

- The flow is 20 L/S! Q = 20, L/S = 0.02 m^3/SThe total efficiency of the pump and the motor is estimated to be 60%P=pgHQ/n=1000*9.8*90*0.02/60%=29400W= 29.4, KWLook at the water pump motor power 30KW just enough from the calculation, but there is no room for the use of the attention do not overload!(Note: motor power matching pump nameplate are generally too large, room.)

- Q:I took my 04 Grand Prix to the mechanic for a coolant change. My car had never drip coolant until after the coolant change . I took my car today to the same mechanic and he told me that the problem was the water pump and wants to charge me 70 dollars. Could changing the coolant affect the water pump. Or did the mechanic damaged the water pump on purpose.

- Changing coolant would not make it start leaking. MAYBE if someone before had used some sort of stop leak garbage, but that's pretty unlikely. That car has probably been around the block for some time, it's likely just coincidence. However, it shouldn't be hard to find one of your friends that can crawl under the car and confirm what the problem is. Could just be a loose hose clamp.

- Q:I've searched the net but cannot find exactly what I'm looking for and hoping someone out there can steer me in the right direction! Maybe I'm not looking in the right place....or do I have to fabricate my own? I'm up for the challenge!1) Trying to source a water pump that I'm going to power by HAND or a BICYCLE. 2) My choice of pump to give a continuous stream of water (very important) is a rotary (centrifugal) type or is there something else capable of a continuous output?3) This will NOT BE USED for potable water. SPECS:a) lightweight but durable, the smaller, the better. b) low RPM, high volume output and capable of producing/handling pressure. c) self-primingd) able to handle some small particulates in the water as I am using rain water. (from outside, NOT filtered, so the following may be present: bugs, dust, etc...) Thank you, in advance, for your help and would be nice to thank the individual(s) for a unique answer to my request at a later date so let me know you're preferred method of contact!

- There are very small rotary water pumps designed to be driven with hand-held electric drills. These pumps may be purchased in some hardware stores or farm supply stores. One could be adapted to a bicycle- type drive. Small pumps have about a 50% efficiency so you would need to produce sustained muscle power applied at around 150-200 watts to achieve 75 -100 watts of effective hydraulics. Applied watts = (GPM) (PSI) / 1.277 million (eff.) Where eff. is as a decimal. Edit : A 3/8 drill will pull about 280 watts. I can do 200 watts on an exercise bike, but not for long. I am a 79 heart patient, so you can probably do better..

- Q:My 2001 300M is behaving oddly. Occasionally it will gradually overheat after I have driven around for 15 or so minutes. Yes, occasionally. I took it to my mechanic who changed the thermostat and hoses. I then drove it on a trip on the interstate and over a mountain (140 miles ) It was fine with no signs of overheating. Then the next day when I drove to work in the city, the stop and go traffic had it overheating near the end of the trip. I've been able to keep it from going in the red by using the heater. After this happened most of the days, but not all, I took it back to the shop. He reported that the fans were working correctly and the only thing he could come up with is a weak water pump. He stated that when it did get hot, he was able to bring the temp down just by rev'ing the engine a little.Does that sound right? Any other ideas and how to test?

- I've okorder

- Q:Can I use Ultra Blue gasket maker on a water pump? The packaging is not labeled high heat.

- Yes, but you have to let the gasket maker cure for at least 24 hours. After you have driven it for a couple days, be sure to re-tighten the flange bolts, as the gasket maker will shrink with heat, causing possible leakage. Good Luck !

- Q:How does a pump pump water?

- Generally speaking, pumps mostly refer to centrifugal pumps. Generally, the centrifugal pump is driven by an electric motor. Before the pump is started, the pump body and the suction line are filled with liquid. When the high-speed rotation of the impeller, the impeller drives the liquid between the blades of a rotation, due to the centrifugal force, the liquid was thrown from the impeller center to the outer edge of the impeller (flow rate can be increased to 15 ~ 25m/s), the kinetic energy is also increased. When the liquid enters the pump shell, the flow rate of the liquid gradually decreases as a result of the gradual expansion of the flow passage in the volute pump housing, and a part of kinetic energy is converted to static pressure, so the liquid flows out at the higher pressure along the outlet. At the same time, the impeller center because the liquid was thrown out and formed a certain vacuum, and the liquid level of pressure Pa than the center of the impeller to be high, so the suction pipe of the liquid in the pressure difference into the pump. The impeller keeps rotating and the liquid is continuously sucked in and out. Centrifugal pump is able to transport liquid, mainly due to centrifugal force, so called centrifugal pump.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stain Steel Centrifugal Pump Impeller China Made

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords