Horizontal Centrifugal Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Set unit

- Supply Capability:

- 1000 Sets Per Month unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

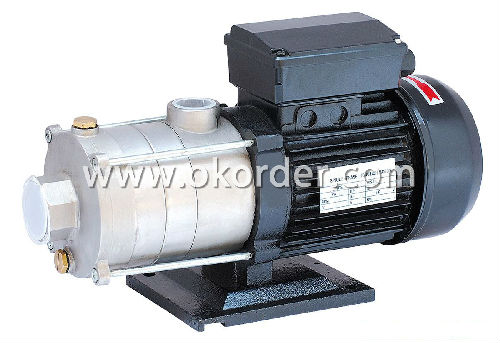

Horizontal Multistage Stainless Steel Centrifugal Pump

1. Applications of Horizontal Multistage Stainless Steel Centrifugal Pump

Cooling water system

Aquiculture

Domestic water supply

General industrial services

Washing

Environment protection

2. Performance Range of Horizontal Multistage Stainless Steel Centrifugal Pump

Capacity: Q up to 323/h

Head: H up to 88m

Temperature: T up to 110℃

Speed: n 2900rpm or 3500rpm

Power: P up to 55 kw *2

3. Standard Material of Horizontal Multistage Stainless Steel Centrifugal Pump

All the parts contact with liquid made of 304 stainless steel, 316 stainless steel on request. The pump head and suction & discharge can be made of cast iron on request too.

4. Description of Horizontal Multistage Stainless Steel Centrifugal Pump

Horizontal multistage design with stainless steel stamping welding impeller and diffuser, three different type for choice.

Single phase motor up to 2.2kw Class F and IP55 motor is standard

Standard supply for liquid temperature up to 70 degree, high temperature pump are available on request.

- Q:1 water pump frequency converter constant pressure water supply wiring diagram

- Light can not be seen in this picture, but also need to see the definition of the terminal on the practical manual, generally speaking, the three terminals are connected to +10V, public and analog signals / multi-function terminals.

- Q:Not sure of the year model but think it is a 1991 to 1995 Jayco 2500FS bumper pull trailer. I bought it to put on a deer lease. One of the previous owners had taken out the water tank which I plan on replacing. I can't find the water pump to see if I need to replace it as well. Also, if you know about how the pump knows when to kick on i.e. pressure switch, push button or what. I know I could take it to have repairs done but enjoy the diy thing. I am in the process of finding out the exact year model as well. Thanks!

- having had many travel trailers the water pump is usually in a cabinet or under a bed or couch with a lot of plastic water lines near where you screw the water hose into the side of the trailer. and they are usually a preset psi from the factory so that is usually nothing to have to worry about and most have an on off switch located in the traier by the kitchen sink.And if the hot water heater is no good look into a tankless water heater it will save you money in the long run but initially you have to have a vent installed up through the roof away from a roof air vent. Another suggestion everytime you move a travel trailer they get the crap pounded out of them and someone needs to go up on the roof with a ladder and/or a plank that goes across the width so there is no weight standing on a roof to make dents or pop seams. Use some plastic stuff like plasticote available at wal mart after you move the trailer and set it up go up and make sure to double coat any of the seams that need it. I crank the heat up inside the trailer and do a double coat the heat rising will put a skin on the plasticote in a few hours instead of 12 or more. and the double coat gets any cracks missed the first time around. After that check it once a year if the trailer stays there.

- Q:as i asked before in my question what needs to be fixed when a water pump goes bad. so finally it went bad today the car leaked all coolant and for some reason all the blades on the fan broke and the battery light came on. which is connected to the alternator belt so thats not the problem. so now does anybody have any idea how much it would cost to fix and by what i know it needs a new belt for water pump and new fan and water pump etc. taking it to mechanic monday but wanna get an estimate first from u people. any ideass thanks

- seems like you pretty much know what you need id say add the belt tensioner they do go bad so while you got it a apart wouldbe smart to go a head and get one also and really since you know whats bad you could replace it all your self seems like you know more than you think none of it will be hard

- Q:Is there a way to test and see if it is the water pump that causes the car heater to blow hot air one time and then, next time it blows cold air? We flushed the heater core and did other tests, so we do not believe it is the heater core. We left the radiator cap off and ran the car (ford thunderbird..'94) for 20 minutes and watched the antifreeze level come up, but doesn't go down, not circulating. We cannot afford to go to another garage. None of them seem to know what to do anywyas and we keep paying people to fix the heater and it is not fixed. We have put two new thremostats in car, too, figuring that maybe the first one may have been faulty, but should we try that again?

- On many cars you cannot see the coolant circulating especially at idle. Just because you do not have heat does not mean the water pump, and if your car is not overheating it is probably - I say probably - doing its job. So stop putting thermostats on, probably assume the water pump is okay. So, put a thermometer into the radiator to see how hot the coolant is getting - should be ~180 degrees or so. Hmmmm - Does this car have an electronic climate control system? Perhaps that is the reason you have an intermittant problem. Assuming manual climate control - It could be a vacuum leak to one of the manual vents that is allowing cool air to mix with the hot. Or, maybe the slider from hot to cold is not working. What troubles me is the intermittant problem here. So, I will go out on a limb and say it could possibly be a bad head gasket for reasons I will not get into here. In any case, Good Luck!

- Q:55KW how large is the water pump wiring?

- The general centrifugal pump is a three-phase squirrel cage asynchronous motor with a power factor of 0.85I=P/U/1.732/COS=55KW/380V/1.732/0.85=98.3A, light load, such as the use of YJV cable, ZR-YJV-0.6/1, 3*35mm2 copper core cable can be, such as heavy load or select VV cable, the cross-sectional area should be extended to 3*50mm2

- Q:What I am trying to explain is that I took my vehicle to be serviced for a water pump. They installed it, but when I got my vehicle back, it started making this clicking noise. I took it back to be diagnosed and they came back to me saying that I need a new engine? (Before I took in my vehicle there was no clicking sound or problems, just the water pump.)Could this be the dealer trying to pull something for their mistake or what?

- Take it to a different Mechanic. Who diagnosed it in the first place? But yes a mis-installed water pump will do about as well as not having one, and they can be pretty important. If it was installed wrong then they are liable for the engine not you.

- Q:How many kinds of pumps are there? What are the advantages of soft start?

- Soft start is prepared, hard start is not prepared, the machine suddenly can not stand! Ha-ha

- Q:Water is pumped upwards 4.000 m into a pool. The flow rate of the water is 4.000 L/min and it takes 10.00 minutes to fill the pool. What is the power of the pump?I would appreciate any help that you can give me - this is a question on an upcoming test!

- g = 10m/s^2 1 : Mass of water per Minute = 4 * 1000g = 4Kg Mass of water per second = 4Kg/60 Height = 4m Work per second = m(per second) g h = Power Power = 4/60*10*4 = 160/60 W = 2.6666W 2: Total Mass of water = 4 * 1000g * 10 =40Kg Height = 4m Work Done = mgh = 40*4*10 = 1600j Power = Work/Time = 1600/(10*60) = 2.6666W This is a Very Small Pump :P Hope this Helps Kaushalya Damitha

- Q:Our mechanic wants to replace my husband's water pump in his 1996 Saturn saying it is quite loose. We'd like to wait until next week since its a 2 day job and with our schedules it would be difficult. Can it wait for a couple of weeks? Could this leave him stranded?

- There is no way of knowing how long it will last. How long has it been going out? What does the mechanic mean by loose? Is it leaking water? It could last a couple of years, it could go out tomorrow. If you trust your mechanic, which I would over people on here, I would have the water pump changed as soon as possible. When it goes out, and it will, it will leave you stranded, and in the most inappropriate place and time.

- Q:Fire pump and spray pump requires a preparation, 2 sets of the same pump requires mutual investment, when the main pump failure of backup pump automatically put into use. 1: so what is the throwing device: 2: where is the device installed? It should be in the water pump control box. 3: what is the principle of mutual voting? Detailed description

- You can refer to the DCL and DCS microcomputer access control system, you can achieve the purpose of remote control. Specific installation methods can be found in local instrument engineering inquiries.

1. Manufacturer Overview |

|

|---|---|

| Location | Zhejiang,China |

| Year Established | 1984 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe |

| Company Certifications | ISO 9001:2000;CE |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | 3,000-5,000 square meters |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered Design Service Offered |

| Product Price Range | |

Send your message to us

Horizontal Centrifugal Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Set unit

- Supply Capability:

- 1000 Sets Per Month unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords