Split Casing Double Suction Centrifugal Water Pump for Irrigation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Split Casing Double Suction Centrifugal Water Pump for Irrigation

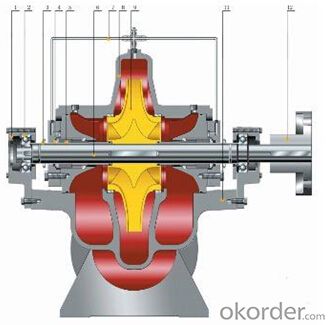

1.Split Casing Double Suction Centrifugal Water Pump for Irrigation Description

The Single Stage Double Suction Split Casing Centrifugal Pump is designed for Irrigation, The casting is axially split, which permits removal of the complete rotor whish moving either piping or motor. Pumps generating high heads have double volute to reduce radial forces. Replaceable wear ring protect the casting at the impeller running clearances. Flange drilled to ISO, DIN, BS or ANSI. The close double suction impeller gives practically zero axial forces. Each impeller is statically and dynamically balanced according to ISO 1940.The pumps have a reduced number of parts and extensive interchangeability, which leads to minimum levels of inventory for customers and faster parts delivery. Vertical installation is a standard option with the same upper and lower casing parts. It is mounted for a space-saving configuration or when apace is at a premium. Soft packing or mechanical seal, grease or oil lubricated bearing is optional. Oil lubrication is with constant level oiler.

2.Main Features of Split Casing Double Suction Centrifugal Water Pump for Irrigation

•Attractive design

•High efficiency, steady performance

•Big capacity, medium pressure

•High concentricity of components

3.Split Casing Double Suction Centrifugal Water Pump for IrrigationSpecification

Casing | Cast Iron, Ductile Cast Iron, Cast Steel, Stainless Steel or Duplex S.S |

Impeller | Cast Iron, Bronze, Duplex S.S, Stainless Steel |

Shaft | C-Steel, Cr-Steel, Stainless Steel |

Wearing Ring | Cast Iron, Brass, Stainless Steel |

Capacity/Q | Up to 25000m3/h, Up to 110000gpm |

Head/H | Up to 280m, Up to 800 feet |

Temperature/T | Up to 200degree |

Speed/n | 2900/1450/980/740/580 rpm 3500/1750/1180/890/710rpm |

4.Picture of Split Casing Double Suction Centrifugal Water Pump for Irrigation

5.FAQ

① What is your product range?

Centrifugal pump, slurry pump, gravel pump, clean water pump, sewage pump, chemical pump, single stage

pump, double suction pump, industry pump, oil pump, paper pulp pump, mud pump, self-priming pump, pipe

water pump, boiler water pump, etc.

② Are you a manufacturer?

Yes, we have been in manufacturing and marketing industry centrifugal pump over 20 years.

③ What information should I let you know if I want to get a quotation?

Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please also provide the pump model you are using now, price will be calculated as per the pump model, if not, we will recommend relevant product for reference.

- Q:Hi, my water pump isn't working in my rover 400i V reg 99 model......does anyone know where under my bonet this is located and whether it's easy done at home?

- water pumps are never an easy fix. most the time you have to take the fan off, and the radiator as well so a person has room to work. MOST water pumps are in front of the motor, towards the bottom. If you follow your radiator hoses you will find it.

- Q:It has a small leak that started this day and it has 60000 miles on it , also new or rebuilt . What is the appr. cost tohave a shop do it ?

- probably not that hard but if you want the best result take it to a shop. but if they dont do good you can always thke them to court lol

- Q:I just came from my dealership and they tested my car with a pressure test. They didnt notice any coolant leaks. Last week my car I noticed that the coolant level has decreased. I had to replenish it in an emergency effort. I am curious to check the water pump. I am going to ask my mechanic tomorrow if he could check it and how much does something like that cost to check? I DO NOT want any coolant leakage getting into my engine because that could present a problem. How can it possibily get to the engine???

- If you had a water pump leak you'd know it! There would be coolant draining out of water pump seal the minute you filled the cooling system. A water pump leak doesn't get coolant into the motor. It will get the timing belt wet with antifreeze and cause the belt to jump time and possibly bend your valves. The only way you'll get coolant in the motor oil is if there is a head gasket leak. To check for that you need to have a block test done.

- Q:I am about to replace the timing belt in a 3.4L Toyota V6 at approximately 85,000 miles. The motor has had the Toyota red coolant, which lubricates a water pump very well. Should I, Or should I not replace a Toyota Water Pump also, at this mileage (85,000)? Could the original water pump last until 170,000? Thank you

- if it works dont fix it .ok .best leave it .

- Q:After the pump has the control box, but also the power distribution box, the control box and the distribution box is not the same box?

- This look at the specific situation, the water pump circuit is divided into power, power and control signal two parts,They can be placed in a larger cabinet, which is convenient for future inspection and repair.There is power and signal is separated from the general distribution box and put some air contactors, frequency converter etc.,There are some buttons, lights, etc. in the control box.

- Q:If a person took a water pump and attached to a hose and ended up with (random numbers) 15 gpm and 30 psi at the end of the hose, what would happen if you put an exact same pump right next to it and hooked the two pumps together with a quot;Yfitting to a single hose? Would both the gpm and psi be doubled, or neither, or just one? What would happen?

- Only the GPM would be doubled if the pumps are connected in parallel as described. The Pressure would remain at 30 psi. If you were to connect them in series you could double the pressure to 60 psi, but the GPM would remain the same.

- Q:I am creating a project where I must pump water to a helmet. If you have any ideas, thoughts, solutions, diagrams, etc. please? thanks

- your question is not clear, do you need to build the pump from scratch or you should find one? what is the water flow rate? how high the water need to go? what the helmet has to do with the problem? simplest solution will be to go to the store and buy small hand pump (for fuel).

- Q:My water pump is losing pressure slowly even though no water is being used. Your help is appreciated. Thank you.

- Water Pump Loses Pressure

- Q:I have an 02 Gran Prix and my water pump is going out. With the recession I don't have the money to take it in. So can anyone give step by step instructions to help me fix it. I am a do it yourself kinda of guy so I am mechanically inclined. What tools will I'll need? is there a timing chain? How long will you think it will take me? Any thing i should pay attention to? How can I measure the pounds of torque that I put on the bolts or what tool will I'll need? Please help!!!

- WP replacement mini-writeup 1. Empy Coolant from Radiator drain 2. Remove SC and Acc. belts 3. Remove the coolant resevoir tank 3. Remove the Idler pulley with a 15mm 4. Remove the 4 WP pulley bolts with a 8mm 5. Remove the 2 Power Steering Pump bolts with a 13mm(bolts are at 12:00 and 6:00 accessable through the PS pulley holes) 6. Push PS pump 1 inch to the side 7. Remove all 8 WP bolts with a 13mm and a 10mm(3 are 13mm/5 are 10mm) 8. Collect extra coolant until flow stops(a few cups) 9. Apply RTV to both sides of the gasket and WP bolts 10. WP bolts should be torqued to 11lbs+80*/Idler pulley bolt at 36lbs/WP pulley bolts at ~9lbs 11. Reinstall everything and fill the coolant back up 12.

- Q:Hello everyone, is the general household deep well pump capacitor how to pick up ah, 220V voltage, a capacitor, capacitor, there are 2 lines, but the motor is 3 lines, how can I put these 7 lines together?.Please don't copy professional theories from others.

- 1) in a line in the AC220V string into a large light bulb (Bai Chideng), and then the capacitor as shown in figure A, then, that B and C are three terminals; 2) the number of pump motor three lines 1, 2 and 3; 3) A, B, C and 1 2, 3, a total of six kinds of wiring combination: ABC/123, ABC/ 231, ABC/321, ABC213, ABC132 ABC312; 4) you have a a try, if you can turn up, and the fastest start wiring is correct, 5) if not turn up, you have to increase the number of watt bulb, such as 200 watts, 300 watts, 500 watts...... With a few 100 watt parallel one; 6) string into the bulb is designed to prevent the current is too large, it certainly must be removed after determining the connection method; 7) there is no suitable bulb that according to the motor power generation to choose the appropriate insurance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Split Casing Double Suction Centrifugal Water Pump for Irrigation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords