Split Casing Double Suction Centrifugal Water Pump for Farm Irrigation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

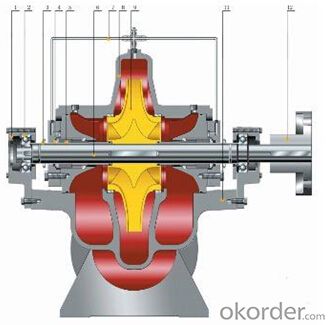

Split Casing Double Suction Centrifugal Water Pump

1.Split Casing Double Suction Centrifugal Water Pump Description

The Single Stage Double Suction Split Casing Centrifugal Pump is designed for Irrigation, The casting is axially split, which permits removal of the complete rotor whish moving either piping or motor. Pumps generating high heads have double volute to reduce radial forces. Replaceable wear ring protect the casting at the impeller running clearances. Flange drilled to ISO, DIN, BS or ANSI. The close double suction impeller gives practically zero axial forces. Each impeller is statically and dynamically balanced according to ISO 1940.The pumps have a reduced number of parts and extensive interchangeability, which leads to minimum levels of inventory for customers and faster parts delivery. Vertical installation is a standard option with the same upper and lower casing parts. It is mounted for a space-saving configuration or when apace is at a premium. Soft packing or mechanical seal, grease or oil lubricated bearing is optional. Oil lubrication is with constant level oiler.

2.Main Features of Split Casing Double Suction Centrifugal Water Pump

•Attractive design

•High efficiency, steady performance

•Big capacity, medium pressure

•High concentricity of components

3.Split Casing Double Suction Centrifugal Water PumpSpecification

Casing | Cast Iron, Ductile Cast Iron, Cast Steel, Stainless Steel or Duplex S.S |

Impeller | Cast Iron, Bronze, Duplex S.S, Stainless Steel |

Shaft | C-Steel, Cr-Steel, Stainless Steel |

Wearing Ring | Cast Iron, Brass, Stainless Steel |

Capacity/Q | Up to 25000m3/h, Up to 110000gpm |

Head/H | Up to 280m, Up to 800 feet |

Temperature/T | Up to 200degree |

Speed/n | 2900/1450/980/740/580 rpm 3500/1750/1180/890/710rpm |

4.Picture of Split Casing Double Suction Centrifugal Water Pump

5.FAQ

① What is your product range?

Centrifugal pump, slurry pump, gravel pump, clean water pump, sewage pump, chemical pump, single stage

pump, double suction pump, industry pump, oil pump, paper pulp pump, mud pump, self-priming pump, pipe

water pump, boiler water pump, etc.

② Are you a manufacturer?

Yes, we have been in manufacturing and marketing industry centrifugal pump over 20 years.

③ What information should I let you know if I want to get a quotation?

Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please also provide the pump model you are using now, price will be calculated as per the pump model, if not, we will recommend relevant product for reference.

- Q:Does anyone know or can show me a picture of the location of the water pump in the '97 Totota avalon please? I'm trying to replace mine.Please and Thank you :)

- Front of engine block, behind fan and driven usually by the crankshaft.

- Q:Why is the water pump usually used multi-stage pumps, while the circulating pump is usually a single-stage pump?

- The circulating pump is usually used in the closed-loop system, circulating pump will be generated when the pump pressure, the pressure is also said, and the suction pump up is in normal pressure system, the outlet of the closed-loop system, when the system pressure is 0.1MPa, the water pump for water system needs higher than 0.1MPa, the difference of pressure difference the greater the water faster, on the contrary, the smaller the slower the pressure difference; so the normal work must want water pump outlet pressure is greater than the system pressure. The replenishment pump is usually multi-stage pumps, and circulating pumps are usually single pump is wrong, as long as the replenishment pressure difference to meet the requirements, multi-stage pumps and single-stage pumps are not affected.(single stage pump and multi-stage pump difference: 1, single-stage pump water level "is a wheel is a level", an impeller, no other brothers and sisters for help; and a plurality of multi-stage pump impeller, there are brothers and sisters for its help, so that his ability to work is high. Just as a man works alone and a lot of people work together, the work is differentTherefore, as long as the design requirements are met, it is not important to select multi-stage pumps and single-stage pumps.

- Q:A guy i know changed the Water pump on my 02 Chrysler Sebring with a 2.7 in it because it was leaking coolant, when i got it back the leak was fixed but now there is a ticking noise. He thinks that the Timing Chain Tensioner needs to be replaced... can i get some opinions here? does he sound correct?

- It is possible. The water pump is driven off the timing chain on that engine. Why didn't he replace the tensioner when it was apart is a good question. The fact that it is now ticking isn't a good sign. I hope it was lined up properly.. get it looked at soon before there is the potential for damage.

- Q:What does the lift of a pump mean?

- The pump lifts water from the surface to the highest point, such as a submersible pump working below the surface of the water. The pump head is still applied to the water level, not the water pump.

- Q:Why is water pumping cool water is normal, but when pumping hot water pressure and flow are very small?

- You look at what you pump that is, there are manuals to see how much the media can not exceed the degree,

- Q:how can i put in a water pump for a1994 bonniville sse?

- Simple. Open the trunk. Put the water pump inside. Close the trunk. Drive the car (or have it towed) to your local mechanic and ask him to install it for you. ;^)

- Q:i have little leak from water pump need to replace it in my mazda 6 2006 v6 3.0l. i have little over 120.000 miles on it. Any body know how much it may cost me?

- I don't know why, but the water pump costs between $125 and $160. That seems a little high. It probably retails for $186. Under normal conditions, you just get things out of the way, unbolt the old pump, clean it up and put the new one in. The problem is the other stuff that gets in the way. I'm just estimating the job will take 5-8 hours. Just multiply times the labor rate in your area. Don't forget the anti-freeze when you're done.

- Q:Hi, I need to create a portable shower and was going to go the DIY route, i wanted to use water pumps normally used in ponds, aquariums etc etc as the means of creating water pressure for the shower, the shower need not be really strong in pressure but it should be strong enough such that a person can take a bath using it.height of the shower would for sure be less then 6 feet,question , water pumps are rated at gallons per minute or some equivalent rating, how strong a pump or how much GPM should i be looking at ?

- Himin newly has launched a solar patented booster pump for non-pressure solar water heater and it's quiet and gives comfortable pressure for shower.This pump fits for area where water pressure is small or rural area.

- Q:I've been hearing a noise from my truck that sounds like a fan blade is rubbing against something metal but I could never figure out what it was and my truck seemed to be running fine. I recently replaced my radiator and now my truck is overheating. Was that noise my water pump going bad and now it's shot?

- could very well be.Also could be fan clutch.

- Q:have a leak in water pump and need to replace.It is easy or very hard

- Not very easy, apparently, but probably not as hard as a timing belt driven water pump is (first source). You don't mention the year or engine, but if you plug your actual info into the estimator in the second source it will give you a better idea. I used a 2000 Focus with 100K miles; it looked like 2 1/2 hours of labor (figuring about $100 per hour) for the dual OHC engine and about 2 hours for the single OHC engine.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Split Casing Double Suction Centrifugal Water Pump for Farm Irrigation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords