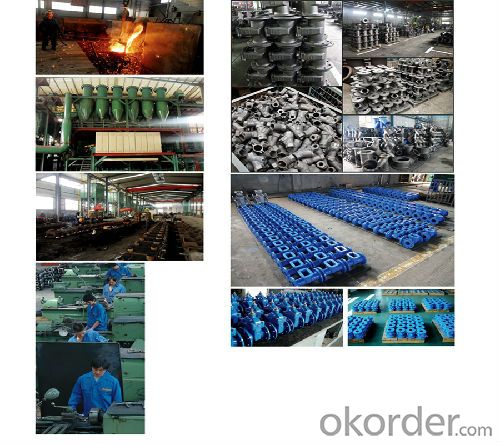

Iron Check Valve DN700 Attractive and Reasonable Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 set

- Supply Capability:

- 6000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Usage/Applications Of Iron Check Valve:

Check valve is to rely on the flow of the media itself and automatically open, close the valve flap, used to prevent the media back valve, also known as the check valve, Dan Xiangfa, counter flow valve, and back pressure valve.

Check valve is an automatic valve, its main role is to prevent the media back, to prevent the pump and drive motor reversal, as well as the release of the container medium.

Technical Date | Material Specification | ||

Nominal Diameter | DN40-DN1000 | Valve Body | Cast Iron or Ductile Iron |

Nominal Pressure | PN10/PN16 |

Valve Disc | Cast Iron or Ductile Iron or Stainless Steel |

Operation Temperature | -40°C~225°C | ||

Flange Driling Standard | EN 1902-2 PN10/16 | Seal Material | EPDM OR NBR |

Suface Treatment | Painting |

Valve Spring |

Stainless Steel |

Application | Portable water, water distribution service & feed lines, sewage disposol, irrigation, fire protection pipe systerm, etc. | ||

Packaging & Delivery

| Packaging Details: | Usually is standard export packing with Plywood Case and also can upon customers' requirement |

| Delivery Detail: | Upon customer's requirement |

Specifications

1.cast iron body and caps

2.blow-out proof stem

3.reduce /full bore

4.Certification:ISO9001:2008

- Q:What are the ten major brands of copper check valves?

- I knew that:1, Amico2, Jie Kelong3 crown4, good day5, KITZ

- Q:Fire hood fire check valve okay?

- The utility model relates to a fire fighting check valve for a range hood, which belongs to an innovative product and can be used.

- Q:Are check and check valves the same kind of thing?

- Yes, that's right. Ha-ha。 My friend needs an anti - stop valve to find me. I have one for sale here.

- Q:Check valve symbols?

- The valve that prevents the backflow of the medium is called a check valve. Check valves belong to the automatic valve, mainly used for one-way flow of media channels, allowing only medium to flow in one direction, to prevent accidents.

- Q:What does the H/F/P stand for in the check valve H41H/H41F/H41P?

- The first H represents the check valve, the 4 represents the flange, and the 1 represents the lift type, and the second H represents the seat seal surface. The material is alloy steel or stainless steel. The P H41P said seating for boron steel

- Q:What is the function of the check valve?

- 1. Check valve function: prevent backflow of medium, prevent pump and drive motor reverse, and discharge of container medium.2, check valve refers to rely on the flow of the media itself and automatically open and close the valve, used to prevent the media back of the valve, also known as check valve, one-way valve, counter flow valve, and back pressure valve. The check valve belongs to an automatic valve.3, check valve according to the structure of the division, can be divided into lift check valve, swing check valve and butterfly check valve three:Lift check valve is divided into two types of vertical and horizontal.Swing check valve is divided into single, double valve and multi flap type of three.Butterfly check valve is straight through type.The above types of check valves can be classified into thread connection, flange connection, welding connection and clamp connection in connection forms of four kinds.4, check valve (Check, Valve) installation should pay attention to the following mattersA do not allow the check valve to bear weight in the line, and the large check valve shall be independently supported so as not to be affected by the pressure generated by the piping system.B, when installing, pay attention to the direction of the flow of medium should be in accordance with the direction of the body marked arrow.C and vertical vertical check valves shall be installed on the vertical pipe.D and lift type horizontal check valves shall be installed on horizontal pipes.

- Q:What is the HH44X-16 H of the double acting slow closing check valve? Can you explain it in detail?

- 2, micro resistance, slow closing check valve, also known as check valve, its role is to prevent the medium back in the pipeline. The opening and closing parts depend on the flow of the medium and the power is turned on or off by itself. The valve that prevents the backflow of the medium is called a check valve. Check valves belong to the automatic valve, mainly used for one-way flow of media channels, allowing only medium to flow in one direction, to prevent accidents. Suitable for cleaning medium, not suitable for medium containing solid particles and viscosity.

- Q:Check valve is 150, why not put 150 of the smoke pipe?

- DN150 check valve, it is possible that the internal path is less than the required value of 5mm-10mm. Therefore, the 150 outer diameter of the smoke pipe is not up.

- Q:Butterfly micro stop type check valve HH46XP-10Q, what does the letter mean?

- The first H stands for slow closing, the second H represents the check valve, the X represents the sealing surface, and the rubber, the P represents the butterfly plate, and the stainless steel Q represents the ductile iron.

- Q:What does the check valve "H44Y-160" mean?

- Take a look at that JB/T 308 valve model compilation standards, which explain very clearlyH check valve, 4 flange connection, 4 spiral structure, Y is hard sealing hardfacing alloy. 160 is nominal pressure

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Iron Check Valve DN700 Attractive and Reasonable Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 set

- Supply Capability:

- 6000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords