QTZ80 (6010A) tower crane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 12 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

QTZ80(6010A) tower crane tower crane is novel hoisting and conveying machinery which is designed by fully utilizing the group technology, the combinational design technology and the finite element analysis technology and taking the tower crane microcomputer design platform as a tool.

The crane is a horizontal-arm-rest trolley-amplitude upper-revolution hydraulic lifting type crane which has the maximum working amplitude of 56m, the independent lifting height of 40m, the adhesion lifting height of 150m, the rated lifting moment of 710kN•m and the maximum lifting moment of 853.2kN•m. All the performance parameters and technical indexes of the crane meet or surpass national standards.

The crane features advanced parameters, excellent and reliable properties, attractive appearance, high quality, simple and practical structures, advanced safety devices, convenient maintenance, safe usage and reasonable prices, and is ideal construction machinery for many construction enterprises.

The lifting boom and balance boom adopt cantilever boom structure, which reduces the hoisting modular and makes it more safe, convenient and flexible to install and uninstall, and reduces the requirements for hoisting equipment and the site.

2. Multiple special mounting brackets are available, which saves the installation time and ensures safe and quality installation.

3. The lifting boom adopts cantilever boom structure and variable cross-section materials, featuring more reasonable structural stress and long service life; and it is easier to make different combination of boom length.

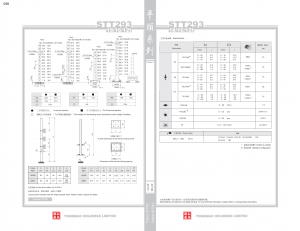

| Amplitude(m) | 3-13.6 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 |

Lifting capacity(kg) | 4000 | 3890 | 3618 | 3380 | 3170 | 2860 | 2810 | 2660 | 2530 | 2400 | 2290 |

Amplitude(m) | 24 | 25 | 26 | 27 | 28 | 29 | 30 | 31 | 32 | 33 | 34 |

Lifting capacity(kg) | 2190 | 2090 | 2000 | 1920 | 1850 | 1770 | 1710 | 1650 | 1590 | 1540 | 1490 |

Amplitude(m) | 35 | 36 | 37 | 38 | 39 | 40 | 41 | 42 | 43 | 44 | 45 |

Lifting capacity(kg) | 1440 | 1390 | 1350 | 1310 | 1270 | 1230 | 1200 | 1170 | 1130 | 1100 | 1070 |

Amplitude(m) | 46 | 47 | 48 | ||||||||

Lifting capacity(kg) | 1050 | 1020 | 1000 |

(2)2-magnification Lifting Performance Table

Amplitude(m) | 3-26 | 27 | 28 | 29 | 30 | 31 | 32 | 33 | 34 | 35 |

Lifting capacity(kg) | 2000 | 1920 | 1850 | 1770 | 1710 | 1650 | 1590 | 1540 | 1490 | 1440 |

Amplitude(m) | 36 | 37 | 38 | 39 | 40 | 41 | 42 | 43 | 44 | 45 |

Lifting capacity(kg) | 1390 | 1350 | 1310 | 1270 | 1230 | 1200 | 1170 | 1130 | 1100 | 1070 |

Amplitude(m) | 46 | 47 | 48 | |||||||

Lifting capacity(kg) | 1050 | 1020 | 1000 |

Technical Performance Parameter Table

Item | Unit | Magnification | ||

α=2 | α=4 | |||

Rated lifting moment | kN.m | 500 | ||

Maximum lifting capacity | t | 2 | 4 | |

Working amplitude | m | 3 ~48 | ||

Maximum amplitude lifting capacity | t | 1.0 | ||

Lifting height | Independent | m | 30 | |

Attached | m | 120 | ||

Time of moving outrigger end to rotation center | m | 48.74 | ||

Time of moving balance arm tail to rotation center | m | 12.816 | ||

Counter weight | t | 7 | ||

Total motor power | kW | 24.9 | ||

Allowable working temperature | 0C | -20~+40 | ||

- Q:Tower crane; command; gesture

- 1. prepare (note): arm extension, placed above the head, five fingers stretched out naturally, palm forward remain motionless.2. main hook: single hand natural fist, in the head, touch the head3. auxiliary hook: a hand clenched, small arm to immobile on the other hand, elbow, hand hand touch before.4. hook up: small arm to the side of the upper extension, five fingers natural extension, higher than the shoulder, with the wrist as the axis rotation.

- Q:A lot of condos and hotels are being build in hawaii, and each time i drive pass them i wonder how they are assembled.Since each individual piece looks heavy/sturdy and is 45 stories+ high, how do construction workers put them together. Do they assemble it by hand? Or are smaller cranes needed to do the job? Or possibly a different way i didn't mention?

- I saw one erected once - it was fascinating. They started out with a big mobile crane - then they added piece by piece until they finished it.

- Q:Tower crane body standard section connection bolt screw upward or downward, why?.

- A few days ago, a special training course of mechanical equipment, a safety supervision station old experts say the screw from the upward wear, stress is the same, but if the nut screw will fall off, in order to find problems. If you can't get it off the top and bottom nut, you won't find it

- Q:Tower crane 4 how to change the rate of 2 magnification, how to change, say detailed points

- At this point, the rope will be turned into 2 fold!Some manufacturers produce pulley, also need to be in the car, and then the magnification pulley with pin shaft fixed in the car!

- Q:What are the main parameters of a tower crane?

- For car luffing tower cranes, the maximum lifting height is only related to the height of the tower, and when the height of the tower is determined, the maximum height of the ceiling is a certain value.In addition to the 4 major performance parameters. And the working speed (including lifting speed, rotary speed and walking speed of car, traction speed), an important parameter gauge, wheelbase, total power, motor structure weight, balance and gross weight, etc.. These important parameters often determine the tower crane selection, such as speed of operation often determines the number of selected cranes, motor power requirements of power supply load, gauge, wheelbase of the site, and the structure weight, balance weight, weight of the foundation treatment of heavy machine requirement.Tower crane (tower crane) is called tower crane, also known as tower crane. A revolving crane mounted on top of a tall tower. The working space is large, mainly used for the vertical and horizontal transportation of materials and the installation of building components during the building construction. The tower crane consists of three parts: metal structure, working mechanism and electrical system. The metal structure includes the tower, the boom and the base. The working mechanism has four parts, lifting, luffing, turning and walking. The electrical system consists of motors, controllers, power distribution cabinets, connecting lines, signals and lighting devices, etc..

- Q:Which is the main basis for the disassembly and assembly process planning of tower cranes?

- 12 installation process;13 safety device debugging;14 major hazard installations and safety technical measures;15 emergency plan.2.0.12 tower crane disassembly special program should include the following content:1 project overview;2 plane and elevation of tower crane position;3 disassembly order;Weight and suspension position of 4 parts;5 disassembly type, performance and layout of auxiliary equipment;6 power settings;7 construction personnel allocation;8 rigging and special tools;9 major hazard installations and safety technical measures;10 emergency plan.

- Q:Please no direct translations. I need the official name of the whooping crane in French.

- grue de huée

- Q:LCS , MCS , HCS?

- Good question! I have lots of experience driving cranes lifting boats in and out of the water mainly. But I don't really think this ever occurred to me. So I had a look around on the old www - which I do not usually do, much, in 'Answers'. But here's your answer, I reckon (another interesting QA site, too! - I leave you the thread in Source(s).): The steel used for crane hooks are based on the application. For cold temp. use you'll need LCC or low temp carbon steel (requiring Charpy Impact values of 15 foot pounds at - 25 degrees F. The materials used can be either cast ASTM A148, or 9060, or A487 4B or a forged 4140 material. All have the properties in the ASTM specs (see specs on line . com). All of these specs have specific heat treats that are part of the individual specs.

- Q:What are the luffing, slewing, and walking points of a tower crane?

- The luffing of a tower crane is the forearm of a crane;Slewing means the steering mechanism of a crane;Walking means the walking trolley on the luffing range of a crane

- Q:inventor of junk yard electromagnetic crane?

- Who Invented The Electromagnet

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

QTZ80 (6010A) tower crane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 12 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords