LUFFING TOWER CRANE STL330

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 2000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

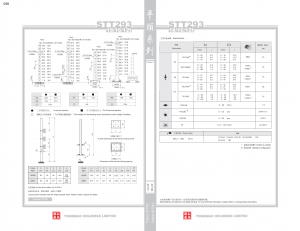

Luffing Tower Crane STL 330 Technical Data

Item | Parameter | ||||||||

Free standing height (m) | 48.3 | ||||||||

Load Moment(t.m) | 304.2 | ||||||||

Max. Load(t) | 12 | ||||||||

Jib Length(m) | 60 | ||||||||

Tip load ( t) | 2.4 | ||||||||

Details of Luffing Tower Crane STL330 Technical Data

1 Hoisting Mechanism

Three-gear speed modulation by electrical motor or frequency conversion, giant winch.

2 Rotation Mechanism

Speed modulation with frequency conversion, stable break, accurate position,

outstanding on performance and operation all around the world.

3 Luffing Mechanism

Speed modulation with frequency conversion, less concussion, stable operation.

Widely used in urban super-high-rise building construction, bridge construction, port construction,

electric power construction, water conservancy construction,

shipyard and nuclear power plant construction,

STL330 luffing crane has a better market prospect thanks to its small tail slewing radius and compact counterjib structure.

It is suitable for working environment with group of tower cranes and crowded buildings.

Packaging & Delivery

1.Package: nude and wooden boxes in containers.

2.Period of shipment: 30 days after receipt of the buyer's advance payment.

- Q:Military Action movie with bunch of cranes at the end?

- Cranes like construction equipment or Cranes like the birds?

- Q:In the U.S. please and tell me where and how you got the number.Thanks!!!

- There are so many overhead cranes in operation today in the US and around the world. They could be numbering in tens of thousands in industries and other operations. An overhead crane, commonly called a bridge crane, is a type of crane found in industrial environments. An overhead crane consists of parallel runways with a traveling bridge spanning the gap. A hoist, the lifting component of a crane, travels along the bridge. If the bridge is rigidly supported on two or more legs running on a fixed rail at ground level, the crane is called a gantry crane (USA, ASME B30 series) or a goliath crane (UK, BS 466). Unlike mobile or construction cranes, overhead cranes are typically used for either manufacturing or maintenance applications, where efficiency or downtime are critical factors. Have a pleasant day.

- Q:I have to read this book for an AP class next year. I did read the book and i don't understand how i can discuss the setting and its possible relationship to the theme. I looked stuff up on the internet and I've asked other people who have read the book and they're just as confused as I am. I need help!

- I can't tell you what to write or what you see as the theme but one of the themes in the book is man versus nature. Maybe you could discuss the setting as part of nature and what Crane seems to be saying about it. One thing that might help is a poem Crane wrote which explains how he sees things. Maybe you already know it. It's titled A man said to the universe A man said to the universe, Sir, I exist! However, replied the universe the fact has not created in me a sense of obligation. An indifferent universe. Not unlike how Thomas Hardy saw things.

- Q:All types of jack up cranes. How is the maximum lifting torque converted?

- Tower crane lifting torque = crane maximum lifting weight * maximum operating range; for example: the maximum lifting weight is 2T*, the maximum operating range of 50 meters =1000KN.m.

- Q:i just ordered a new JG 614 crane stock and do not know how to use the crane stock i would like to learn before it arrives can i have a link to a video or explanation please

- You first need a crane stock battery, as a normal battery won't fit in just one side of the crane stock. When you but the battery, you'll have two or three clusters of cells. Begin experimenting with the cord placement in the stock, by putting one cluster on one side and one (or two) on the other. You'll see what I mean when you get the gun. That's all there is to it, just a little experimenting.

- Q:Whenever a vista shot of London comes up, there are a ridiculous amount of cranes. What's up? Are they always building something?

- At present a large number of tall buildings are being erected in London which accounts for the cranes. One area in particular is around Vauxhall, where there was an accident recently when a helicopter crashed into a crane being used for such a purpose. Just have a look at this www.guardian .uk/artanddesign/2...

- Q:Two cranes are lifting identical steel beams at the time.One crane is putting out twice as much power as the other assuming friction is neglible, what can you conclude is happening to explain this difference?

- You suggested they are lifting comparable metallic beams. we do no longer be responsive to if the cranes are comparable of their overall performance. Are they the two lifting the load in an analogous way? would be one is shifting it vertically against gravity and yet another one is shifting it horizontally. The motor performance and the operator studies would be diverse. using and coasting would reason substantial adjustments.

- Q:explain thoroughly please

- Sure. Let's say that a crane needs to hoist a load of 10 tons, and that because it needs to reach over some obstacles, needs to lift at a horizontal distance of 50 feet away. That creates a torque about the base of the crane of 500 ton·ft. By positioning a counterweight on the opposite side of the tower, the magnitude of the moment can be mitigated. For instance, let's say a counterweight of 10 tons is positioned at 25 ft on the other side of the tower. The moment produced by the counterweight is 250 ton·ft, so the net moment at the base is 250 ton·ft. Furthermore, when the 10 ton load is positioned and release, there is still a 250 ton·ft moment at the base of the tower; it has simply switched direction (say from rotating the crane to the right, to rotating it to the left). If you find this helpful, please award Best Answer!

- Q:Construction tower crane operator certificate expires, how to verify?

- Six, related requirementsEach enterprise shall, according to the notification requirements, arrange the personnel engaged in the work of this unit, and invite every unit to earnestly examine and clean up, and those who have not obtained the certificate will sign up for the training. The certificate into the industry qualification management, obtain the job qualification certificate, can engage in the corresponding work, and as an important basis for certification.Seven, registration requirements and locationsStarting from now on, please bring your ID card copy and one inch registration photo for you when you sign up for two. Fill in "Chongqing construction crane operator qualification table", the applicant's employer to the District Construction Committee, post training center application.Contact: He Zongfang, Hu Baofeng, zip code: 401120Tel: 67376688 Fax: 67800098E-mail:ybjsgp@163 Http://www.cqybjs (Yubei construction information network)Hereby notifyChongqing Yubei District construction post training centerFebruary 20, 2008

- Q:because i have this huge sofa i need to get to 2nd floor but i cant coz the staircase is too small

- Talk to a lumber yard that has a boom truck. Ask them how much to do it. A boom truck will cost much less than a crane. A boom truck can reach 45 to 50 feet. In this economy they are looking for anything they can get. They will most likely do it. But when really busy they wont. But things are slow. Builder 30 years. A crane will cost about 250.00 of the first hour. with a one hour min.

1. Manufacturer Overview |

|

|---|---|

| Location | LIAONING,CHINA |

| Year Established | 2006 |

| Annual Output Value | Above US$5 Million |

| Main Markets | CHINA |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Dalian |

| Export Percentage | 0.6 |

| No.of Employees in Trade Department | 500People |

| Language Spoken: | English;Chinese; |

| b)Factory Information | |

| Factory Size: | Above125,000square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

LUFFING TOWER CRANE STL330

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 2000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords