Hot Rolled unequal Angle Steel for High Voltage Transmission Tower

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description:

Specifications of Hot Rolled unequal Angle Steel for High Voltage Transmission Tower

1.Standards:GB,ASTM,

2. Invoicing on theoretical weight or actual weight as customer request3.Material:GBQ235B or Equivalent;ASTMA36;EN10025,S235JR.

3. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

4.Sizes:

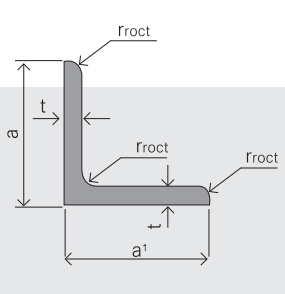

EQUAL ANGLES SIZES |

| ||

a(mm) | a1(mm) | thickness(mm) | length |

100 | 100 | 6.0---12.0 | 6M/9M/12M |

120 | 120 | 8.0-12.0 | 6M/9M/12M |

130 | 130 | 9.0-12.0 | 6M/9M/12M |

140 | 140 | 10.0-16.0 | 6M/9M/12M |

150 | 150 | 10---15 | 6M/9M/12M |

160 | 160 | 10---16 | 6M/9M/12M |

180 | 180 | 12---18 | 6M/9M/12M |

200 | 200 | 14---20 | 6M/9M/12M |

Usage & Applications Hot Rolled Angle Steel

According to the needs of different structures, Angle can compose to different force support component. It is widely used in various building structures and engineering structures such as roof beams, hoisting machinery and transport machinery, ships, container frame and warehouse etc.

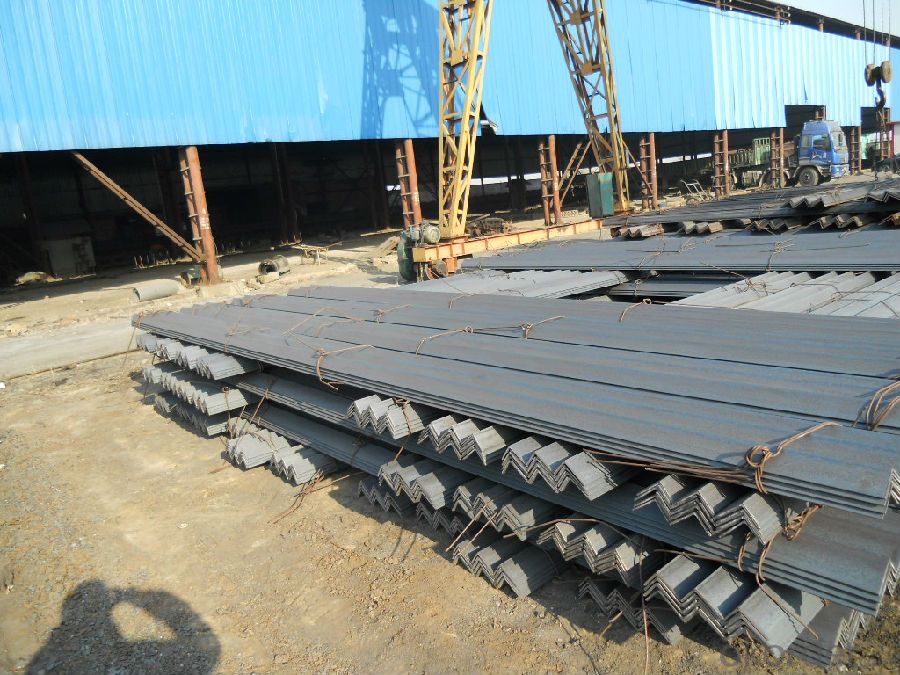

Packaging & Delivery of Hot Rolled unequal Angle Steel for High Voltage Transmission Tower

1. Transportation: the goods are delivered by truck from mill to loading port, the transportation cost per ton will be little higher than full load.

2. With bundles and load in container, or by bulk cargo, also we could do as customer's request.

- Q:Are steel angles suitable for supporting rooftop equipment?

- Indeed, rooftop equipment can be supported by steel angles. In the realm of construction and engineering projects, steel angles are widely employed due to their robustness and endurance. They furnish a dependable and firm framework for various rooftop equipment, encompassing HVAC units, solar panels, and communication antennas. Facilitating effortless fabrication and installation, steel angles can be tailored to meet precise load prerequisites, thereby presenting an optimal option for sustaining weighty machinery atop roofs. Furthermore, their resistance to corrosion guarantees prolonged efficacy and minimal upkeep requirements.

- Q:What are the different types of corrosion that can affect steel angles?

- There are several different types of corrosion that can affect steel angles, including general corrosion, pitting corrosion, crevice corrosion, galvanic corrosion, and stress corrosion cracking.

- Q:What are the common shapes and dimensions of steel angles?

- Steel angles are commonly available in a variety of shapes and dimensions to suit various applications. The most common shapes of steel angles are L-shaped or right angles, with equal legs or unequal legs. These angles are typically formed by bending a piece of steel into the desired shape. In terms of dimensions, steel angles can vary in size depending on their intended use. The length of the legs, which are the two sides of the angle, can range from a few inches to several feet. The thickness or gauge of the steel used to make angles can also vary, with thinner gauges being more lightweight and thicker gauges providing greater strength. The most common dimensions for steel angles include: - Equal Leg Angles: These angles have legs of equal length, forming a 90-degree angle. Common sizes for equal leg angles range from 1/2 inch to 6 inches in leg length, with thicknesses ranging from 1/8 inch to 1/2 inch. - Unequal Leg Angles: These angles have legs of different lengths, forming a 90-degree angle. The longer leg is typically referred to as the "vertical leg" and the shorter leg as the "horizontal leg." Common sizes for unequal leg angles range from 1 inch to 6 inches in vertical leg length, with thicknesses ranging from 1/8 inch to 1/2 inch. It's important to note that these dimensions are just a general guideline, and steel angles can be custom-made to meet specific requirements. Additionally, steel angles can be hot-rolled or cold-formed, which affects their structural properties and manufacturing processes. Therefore, it's essential to consult the specific standards and regulations applicable to your project or industry when selecting steel angles.

- Q:Are steel angles resistant to dynamic loads?

- Generally, steel angles exhibit resistance to dynamic loads. Steel is a durable and robust material that can withstand a variety of loads, including those that change in magnitude or direction over time, such as impact loads, vibrations, or seismic forces. Steel angles, which are also referred to as angle irons or L-shaped structural steel, find widespread use in the construction, engineering, and manufacturing industries due to their high strength-to-weight ratio and versatility. They effectively distribute and transfer loads, providing stability and support to structures. The resistance of steel angles to dynamic loads can be attributed to their inherent properties, including high tensile strength, excellent ductility, and toughness. These properties enable steel angles to absorb and dissipate energy from dynamic loads, thereby minimizing the risk of structural failure or damage. Furthermore, steel angles can be reinforced through various methods, such as welding, bolting, or bracing, to further enhance their resistance to dynamic loads. By employing these reinforcement techniques, steel angles can be customized to meet specific dynamic load requirements, ensuring the integrity and safety of the overall system. However, it is important to consider that the resistance of steel angles to dynamic loads may be influenced by several factors. These factors include the specific grade and quality of the steel, the dimensions and configuration of the angle, the magnitude and frequency of the dynamic loads, and the overall design and construction of the structure. It is, therefore, crucial to consult with structural engineers and adhere to relevant building codes and standards to select and implement steel angles appropriately for dynamic load applications.

- Q:Can steel angles be used for framing windows?

- Indeed, framing windows with steel angles is a viable option. Widely employed in construction, steel angles offer supplementary structural support and stability as window frames. Their durability, strength, and ability to resist warping or bending make them well-suited for this task. Moreover, steel angles can be effortlessly tailored and modified to match the precise measurements and specifications of the window frame, ensuring a secure and accurate installation.

- Q:Can steel angles be galvanized?

- Yes, steel angles can be galvanized. Galvanization is the process of applying a protective zinc coating to steel to prevent rusting and corrosion. Steel angles, which are L-shaped structural components, can be galvanized by immersing them in a hot bath of molten zinc or by applying zinc using a specialized spray or paint method. Galvanized steel angles are commonly used in construction, manufacturing, and outdoor applications where protection against rust and corrosion is essential.

- Q:Can steel angles be used for load-bearing walls?

- No, steel angles are not typically used for load-bearing walls. Load-bearing walls require structural support and are typically constructed using materials such as reinforced concrete or steel beams/columns. Steel angles may be used for non-load-bearing purposes such as framing or decorative purposes.

- Q:What is the thickness of the national standard 8# angle steel? Thank you

- Angle called angle, the steel strip is perpendicular to each other on both sides into the corner. There are equal angles and unequal angles. The two sides of an equal angle steel are equal in width. The specifications are expressed in millimeters of edge width * edge width * edge thickness. Such as "/ 30 x 30 x 3", that is 30 mm width equal angle, edge thickness of 3 mm.

- Q:What are the load-bearing capacities of different sizes and types of steel angles?

- The load-bearing capacities of different sizes and types of steel angles can vary depending on various factors such as the type of steel, size of the angle, and the specific application. Steel angles are commonly used in construction and engineering projects to provide structural support and stability. The load-bearing capacity of a steel angle is primarily determined by its cross-sectional area, which is influenced by the size and thickness of the angle. Larger and thicker steel angles generally have higher load-bearing capacities compared to smaller and thinner angles. The American Institute of Steel Construction (AISC) provides guidelines and tables that specify the allowable loads for various steel angles based on their dimensions and the type of steel used. These tables consider factors such as the angle's shape, length, and the orientation of the load. It is important to note that load-bearing capacities can also be influenced by the specific type of steel used in the angle. Different types of steel, such as carbon steel, stainless steel, or alloy steel, have varying mechanical properties that affect their load-bearing capabilities. For example, stainless steel angles tend to have higher load-bearing capacities and better corrosion resistance compared to carbon steel angles. It is recommended to consult engineering handbooks, structural design codes, or consult with a professional engineer to determine the specific load-bearing capacities of different sizes and types of steel angles for a particular application. These resources provide detailed information and calculations based on industry standards to ensure the safe and efficient use of steel angles in structural designs.

- Q:What are the standard tolerances for steel angles?

- The tolerances for steel angles can vary depending on the angle's specific grade and size. Generally, dimensional tolerances and straightness tolerances are included in the standard tolerances for steel angles. Dimensional tolerances pertain to the allowable variations in the angle's dimensions, including thickness, width, and length. These tolerances are usually expressed as a range or the maximum allowable deviation from the specified dimensions. On the other hand, straightness tolerances deal with the permissible deviation from a straight line that the angle can have. This is typically assessed by placing a straight edge along the angle's length and measuring the maximum gap between the straight edge and the angle. It is important to highlight that the appropriate tolerances for steel angles should be determined based on relevant standards and specifications provided by industry organizations or regulatory bodies. These standards and specifications will offer the necessary guidance on the acceptable tolerances for steel angles based on their intended use and application.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled unequal Angle Steel for High Voltage Transmission Tower

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords