Horizontal Double Suction Centrifugal Water Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

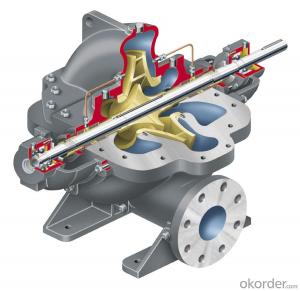

Horizontal Double Suction Centrifugal Water Pump

General Introduction of Horizontal Double Suction Centrifugal Water Pump

According to market needs, Split-case single-stage double suction centrifugal water pump is developed in the broad absorption of advanced technology. Its remarkable characters are as follows: perfect, excellent general model, novel structure, convenient repair. This pump currently produced by our company have fall into more than 40 categories, nearly 400 specification products. We had improved pump impeller and impeller diameter to lead to its impact framework and increasing efficiency. In the spectrum performance range, we can provide any water pump that meets users’ need for pump head and flow.

Sophisticated products and complete quality control, reach domestic advanced standard. We have IS09001 certificate so we can ensure its quality.

This series of water pumps are in accordance with lS02548C, GB321 6C, GB/T5657 standard.

Application of Horizontal Double Suction Centrifugal Water Pump

This pump is widely used in city water supply and drainage, urban water supply; water supply and drainage of central heating system; iron and steel metallurgy, petrochemical refineries, paper mills, oil fields, power plant, airport construction, chemical plants, textile mills, sugar refinery, chemical plant, power plant water supply and drainage, the factory, mine fire water supply system, air conditioning system of water supply, farmland irrigation and drainage, and all other kinds of water engineering.

FAQ

Q: Can your pumps mount Eff.1 motors

A: Currently, only on request though this will shortly be a CNBM standard.

Q: Are your pumps protected against dry running?

A: No, unprotected centrifugal pumps are not generally designed for dry running. It is important to give us or your dealer as much information as possible about the system in which the pump is used. Inlet pressure, the type of liquid to be pumped, together with relative density, viscosity and temperature, for example, are required in order to allow CNBM to recommend the right pump with the right gaskets for a long operating lifetime.

Q: How can I get trained on CNBM products?

A: Yes, we provide training courses in our factory (products, general and specific pump technology, hydraulics, and practical applications). Please consult your sales manager or get in touch with our headquarters for more information.

Q: Are your pumps cheaper than those of your competitors?

A: CNBM aims to give its customers the highest standards of quality and service and delivery times, all at a reasonable price.

- Q:Can an air pump be used for inflatable water slides for lakes?

- An air pump is capable of being utilized for inflatable water slides in lakes. In truth, an air pump is indispensable for the process of inflating and maintaining suitable air pressure in the water slide. By supplying a continuous flow of air into the inflatable structure, the air pump enables it to remain inflated, thus guaranteeing a safe and enjoyable sliding experience. It is of utmost importance to verify that the air pump employed is suitable for the specific size and type of water slide being inflated, as different slides may necessitate varying levels of air pressure. Moreover, adhering to the manufacturer's instructions and safety guidelines is absolutely crucial when employing an air pump for inflatable water slides, as this ensures proper inflation while preventing any accidents or damages.

- Q:Can an air pump be used for inflatable arches?

- Yes, an air pump can be used for inflatable arches. In fact, it is the most common method used to inflate them quickly and efficiently.

- Q:Can an air pump be used for inflatable pool slides?

- Indeed, inflatable pool slides can be inflated using an air pump. In fact, it is the recommended approach to achieve full inflation promptly and effectively. By utilizing an air pump, the slide can be inflated swiftly and efficiently, guaranteeing its readiness for utilization. It is crucial to select the appropriate air pump for the specific slide, as various slides may necessitate varying degrees of air pressure. Furthermore, adhering to the manufacturer's inflation guidelines is essential to ensure the slide is adequately inflated and safe for use.

- Q:Are air pumps suitable for inflating air mattresses with adjustable firmness zones?

- Yes, air pumps are suitable for inflating air mattresses with adjustable firmness zones. Air pumps allow for easy and convenient inflation, enabling users to customize the firmness levels of different zones on the mattress to their desired preferences.

- Q:How to prevent air leaks in inflatable structures?

- To prevent air leaks in inflatable structures, there are several steps you can take: 1. Carefully inspect the inflatable structure before use: Before inflating the structure, visually inspect it for any signs of damage or wear. Look for punctures, tears, or loose seams. If you notice any issues, repair them before inflating. 2. Use a protective ground cover: Place a ground cover or tarp underneath the inflatable structure to protect it from sharp objects or rough surfaces that could cause punctures. 3. Properly secure the structure: Ensure that the inflatable structure is securely anchored to the ground or other stable structures. Use stakes, sandbags, or other appropriate methods to prevent it from being blown away or causing stress on the seams. 4. Avoid over-inflation: It's crucial not to over-inflate the structure, as this can put excessive strain on the seams and increase the risk of leaks. Follow the manufacturer's instructions and recommended pressure levels to ensure proper inflation. 5. Regularly inspect and maintain the structure: Periodically check the inflatable structure for any signs of damage, wear, or leaks. Inspect the seams, valves, and any other potential weak points. Fix minor leaks or damage immediately using a suitable repair kit or adhesive recommended by the manufacturer. 6. Keep away from sharp objects: Ensure that the inflatable structure is kept away from sharp objects, such as sharp branches, sharp edges of furniture, or sharp tools. This will minimize the risk of accidental punctures or tears. 7. Store properly when not in use: When not in use, make sure to store the inflatable structure in a clean, dry, and secure location. Avoid exposure to extreme temperatures, direct sunlight, or other harsh environmental conditions that could degrade the material over time. Following these preventative measures will help ensure the longevity and safety of your inflatable structure by minimizing the risk of air leaks.

- Q:How to choose the right air pump for a specific pneumatic cylinder?

- Choosing the right air pump for a specific pneumatic cylinder is essential for ensuring optimal performance and efficiency. Here are a few steps to guide you in selecting the appropriate air pump for your pneumatic cylinder: 1. Determine the cylinder's air consumption: Start by identifying the air consumption requirements of your pneumatic cylinder. This is typically measured in terms of the cylinder's bore size, stroke length, and operating pressure. Consider factors such as the required force, speed, and frequency of operation to determine the necessary airflow. 2. Calculate the required airflow: Once you have the necessary information about the cylinder's air consumption, calculate the required airflow. This can be calculated by multiplying the cylinder's air consumption (in cubic feet per minute or CFM) by a safety factor, typically around 1.2 to ensure adequate air supply. 3. Consider the pump's output capacity: Look for an air pump that can provide the required airflow. The pump's output capacity, measured in CFM, should be equal to or greater than the calculated airflow. It is advisable to choose a pump with a slightly higher output capacity to accommodate any potential increases in the cylinder's air consumption. 4. Evaluate the pump's pressure rating: Check the air pump's maximum pressure rating to ensure it can generate sufficient pressure for your pneumatic cylinder. The pump's pressure rating should be equal to or higher than the maximum operating pressure of the cylinder. 5. Assess power source and compatibility: Consider the power source available for the air pump. Some pumps are electrically powered, while others may require a separate air compressor. Ensure that the chosen pump is compatible with your power source and can be easily integrated into your pneumatic system. 6. Consider additional features: Depending on your specific application, you may want to consider additional features such as noise level, maintenance requirements, and durability. Evaluate the pump's noise rating, ease of maintenance, and overall build quality to ensure it meets your requirements. 7. Seek expert advice if needed: If you are unsure about any aspect of selecting the right air pump for your pneumatic cylinder, don't hesitate to seek advice from industry experts or consult the manufacturer's guidelines. They can provide valuable insights and recommendations based on their expertise and experience. By following these steps and considering the specific requirements of your pneumatic cylinder, you can choose the right air pump that meets your needs and ensures optimal performance and efficiency.

- Q:Can an air pump be used for pneumatic actuators?

- Indeed, pneumatic actuators can indeed utilize an air pump. These actuators, which harness the power of compressed air to generate mechanical motion or force, can benefit from the capabilities of an air pump. Specifically engineered to compress air and supply a constant stream of compressed air, an air pump serves as a reliable source for these compressed air demands. Consequently, this compressed air can be effectively employed to both empower and regulate pneumatic actuators, enabling them to execute their designated operations. By furnishing the essential pressure required to activate pneumatic actuators, the air pump proves itself as an ideal power source for these devices.

- Q:Can an air pump be used for inflatable gardening tools?

- Indeed, an air pump is capable of inflating inflatable gardening tools. The likes of inflatable planters, gardening cushions, and even inflatable greenhouses can be effortlessly inflated by means of an air pump. This apparatus offers a swift and effective method of inflating said tools, rendering them ready to be utilized within minutes. It is of utmost importance to verify that the air pump is suitable for the specific valve employed in the gardening tool, guaranteeing a proper fit and inflation.

- Q:Can an air pump be used for inflating air hockey tables?

- Yes, an air pump can be used for inflating air hockey tables as they typically require a constant flow of air to maintain the playing surface.

- Q:Can an air pump be used for aeration in wastewater treatment plants?

- Aeration in wastewater treatment plants can make use of an air pump. Aeration is a crucial process in wastewater treatment wherein oxygen is added to the wastewater to stimulate the growth of aerobic bacteria. These bacteria decompose organic matter and eliminate pollutants. To provide the necessary oxygen, an air pump is commonly employed to pump air into the treatment system. Typically, the air pump is connected to diffusers or aerators positioned in the wastewater. These diffusers or aerators release the air as bubbles, increasing the contact surface area between the air and the wastewater. This enables efficient oxygen transfer. The air pump can be adjusted to regulate the amount of oxygen supplied to the wastewater, ensuring that the biological processes occurring in the treatment plant are optimized.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Horizontal Double Suction Centrifugal Water Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords