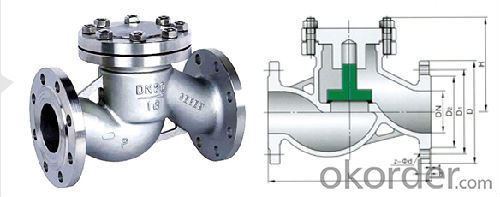

high quality ductile iron cast iron flanged swing check valve

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Quick Details | |||||

| Standard or Nonstandard: | Standard | Structure: | Check | Pressure: | Medium Pressure, 1.0Mpa, 1.6Mpa,2.5Mpa,4.0mpa |

| Power: | Manual | Material: | Casting, cast steel,WCB, stainless steel, ect. | Temperature of Media: | Normal Temperature |

| Media: | Water | Port Size: | DN15-DN300 | Place of Origin: | Tianjin, China (Mainland) |

| Model Number: | Bell | Brand Name: | CMAX | Application: | General |

| Name: | high quality ductile iron cast iron flanged swing check valve | Connection: | Flange | Temperature: | ≤425℃ |

| Standard: | GB,BS,ANSI,JIS,DIN,etc | OEM: | Acceptable | Color: | Customized |

| Certification: | ISO,CE | Warranty: | 12 month |

| Quick Details | |||||

| Standard or Nonstandard: | Standard | Structure: | Check | Pressure: | Medium Pressure, 1.0Mpa, 1.6Mpa,2.5Mpa,4.0mpa |

| Power: | Manual | Material: | Casting, cast steel,WCB, stainless steel, ect. | Temperature of Media: | Normal Temperature |

| Media: | Water | Port Size: | DN15-DN300 | Place of Origin: | Tianjin, China (Mainland) |

| Model Number: | Bell | Brand Name: | CMAX | Application: | General |

| Name: | high quality ductile iron cast iron flanged swing check valve | Connection: | Flange | Temperature: | ≤425℃ |

| Standard: | GB,BS,ANSI,JIS,DIN,etc | OEM: | Acceptable | Color: | Customized |

| Certification: | ISO,CE | Warranty: | 12 month |

Product Feature:

1, the disc lift check valve disc, seat around tunnel axis rotation, due to the channel into a streamline in the valve, flow resistance is smaller than l butterfly check valve, suitable for low velocity and flow not often change the large diameter of occasions, but should not be used for oscillating flow, its sealing performance than lift.Butterfly check valve points single type, double disc type and for the most part three, the three forms mainly by the valve diameter, the purpose is to prevent the backflow medium flow or stop, decrease hydraulic shock.

2, lift check valve: disc revolve around pin in the seat of the check valve.Disc check valve has simple structure, can only be installed in horizontal pipe runs, sealing is good.

3, lift check valve: disc sliding along the center line of the body of the valve.Pipeline check valve is a new kind of valve, its small size, light in weight and good processing technology, is one of the check valve development direction.But the fluid drag coefficient is slightly superior to swing check valves.

| Main performance parameters: | |

| Nominal pressure | PN1.6/2.5/4.0Mpa |

| Suitable temperature | ≤425℃ |

| Applicable medium | Water, oil, gas, corrosive medium, etc |

| Main components | valve body, valve cover, valve, gasket |

| main material | Cast iron, ductile iron, carbon steel, stainless steel |

| Type | DN(mm) | Dimension(mm) | |||||

| L | D | D1 | D2 | z-Φd | H | ||

| HH41W-16Y | 15 | 130 | 95 | 65 | 45 | 4-Φ14 | 90 |

| 20 | 150 | 105 | 75 | 55 | 4-Φ14 | 105 | |

| 25 | 160 | 115 | 85 | 65 | 4-Φ14 | 115 | |

| 32 | 180 | 135 | 100 | 78 | 4-Φ18 | 120 | |

| 40 | 200 | 145 | 110 | 85 | 4-Φ18 | 130 | |

| 50 | 230 | 160 | 125 | 100 | 4-Φ18 | 140 | |

| 65 | 290 | 180 | 145 | 120 | 4-Φ18 | 150 | |

| 80 | 310 | 195 | 160 | 135 | 8-Φ18 | 170 | |

| 100 | 350 | 215 | 180 | 155 | 8-Φ18 | 185 | |

| 125 | 400 | 245 | 210 | 185 | 8-Φ18 | 195 | |

| 150 | 480 | 280 | 240 | 210 | 8-Φ23 | 225 | |

| 200 | 600 | 335 | 295 | 265 | 12-Φ23 | 250 | |

| 250 | 650 | 405 | 355 | 320 | 12-Φ25 | 270 | |

| 300 | 750 | 460 | 410 | 375 | 12-Φ25 | 300 | |

| HH41W-25Y | 15 | 130 | 95 | 65 | 45 | 4-Φ14 | 90 |

| 20 | 150 | 105 | 75 | 55 | 4-Φ14 | 105 | |

| 25 | 160 | 115 | 85 | 65 | 4-Φ14 | 115 | |

| 32 | 180 | 135 | 100 | 78 | 4-Φ18 | 120 | |

| 40 | 200 | 145 | 110 | 85 | 4-Φ18 | 130 | |

| 50 | 230 | 160 | 125 | 100 | 4-Φ18 | 140 | |

| 65 | 290 | 180 | 145 | 120 | 8-Φ18 | 150 | |

| 80 | 310 | 195 | 160 | 135 | 8-Φ18 | 170 | |

| 100 | 350 | 230 | 190 | 160 | 8-Φ23 | 185 | |

| 125 | 400 | 270 | 220 | 188 | 8-Φ25 | 165 | |

| 150 | 480 | 300 | 250 | 218 | 8-Φ25 | 225 | |

| 200 | 600 | 360 | 310 | 278 | 12-Φ25 | 250 | |

| 350 | 650 | 425 | 370 | 335 | 12-Φ30 | 270 | |

| 300 | 750 | 485 | 430 | 390 | 16-Φ30 | 300 | |

| HH41W-40Y | 15 | 130 | 95 | 65 | 45 | 4-Φ14 | 90 |

| 20 | 150 | 1058 | 75 | 55 | 4-Φ14 | 105 | |

| 25 | 160 | 115 | 85 | 65 | 4-Φ14 | 115 | |

| 32 | 180 | 135 | 100 | 78 | 4-Φ18 | 120 | |

| 40 | 200 | 145 | 110 | 85 | 4-Φ18 | 130 | |

| 50 | 230 | 160 | 125 | 100 | 4-Φ18 | 140 | |

| 65 | 290 | 180 | 145 | 120 | 8-Φ18 | 150 | |

| 80 | 310 | 195 | 160 | 135 | 8-Φ18 | 170 | |

| 100 | 350 | 230 | 190 | 160 | 8-Φ23 | 185 | |

| 125 | 400 | 270 | 220 | 188 | 8-Φ25 | 195 | |

| 150 | 480 | 300 | 250 | 218 | 8-Φ25 | 225 | |

| 200 | 600 | 375 | 320 | 282 | 12-Φ30 | 250 | |

| 250 | 650 | 445 | 385 | 345 | 12-Φ34 | 270 | |

| 300 | 750 | 510 | 450 | 408 | 16-Φ34 | 300 | |

- Q:The role of the clip lift check valve

- It only allows the medium to flow in one direction and prevent the flow in the opposite direction. Usually the valve is automatically work, fluid pressure flow in one direction, the valve open; the opposite direction of fluid flow by gravity, fluid pressure and valve closing effect on the valve seat, thereby cutting off flow. Check valves are generally applicable to clean media and are not suitable for media containing solids and viscosity.

- Q:Should the pressure gauge be mounted before or after the check valve at the back of the pump?

- If the pressure gauge is installed before the check valve, the normal pressure will be displayed only when the pump is running. The pressure value displayed at the pump is not consistent with the actual pressure of the pipe.

- Q:What is the function of the check valve?

- The function of the check valve is to prevent the medium from flowing back! Check valves, which are commonly known as check valves! Backflow of medium will cause the reverse of pump impeller, which may lead to the burnout of pump! Pumps used in industry are expensive nowadays! Ha-ha! The check valve just protects the pump and piping!

- Q:What are the types of check valves?

- Taiwan reasonable, this may not have domestic, if you can name, you can call three one-way valve, we can see in accordance with the structure of the spring type.Front Ze valve provides: hope to adopt!!!I hope I can help you.

- Q:I would like to ask you the following questions: Recently, the newly purchased three Lin electric water heater, installed in the upper layer of the five bathrooms, a faucet, that is left to wring out hot water, to the right to wring out cold water, mixed type.1 when there is no safety valve, the hot and cold flow is normal, but the check valve is dripping.2 manufacturers said that the high level to safety relief valve, dripping water and this also concerned, it took more than 100 safety valve, on the cold water pipe, but since then, hot water flow and its small, cold water normal, the check valve is still dripping.3 excuse me, check valve, check valve, safety valve is not a thing? Is it just a different name?4 is the relief valve the same as the relief valve?Now it's really a tough one. How do you solve the problem of small drop of water and hot water flow? The manufacturer said the pressure, but I very cold water washed!Thanks for the answer!

- You called the check valve is also called one-way valve, safety valve has non-return function, also known as relief valve, also can be said as a pressure reducing valve. About 7 kilograms of pressure will generally not Water Leakage, Water Leakage, because of the small water valve and is a function of the filter, open the inlet connecting, you will find a safety valve on the water inlet filter gasket, cleaning.There's no more than 100 in that thing. We're all dead. Send you one.You said that Sanlin manufacturers on this level? Too oftenThe safety valve must be fitted, or the tank will be under great pressure and the hot water will run into cold water.Relief valve function: release, check, filter

- Q:Check valve h44h-25p what does that mean?

- H- check valve code4- flange connection4- rotary single structureH sealing material is Cr13 stainless steel25-25 kg pressure 2.5MPaP- stainless steel 304

- Q:What's the difference between a throttle valve and a check valve? Are they the same?

- The same valve, but the effect is entirely different.The so-called "check back" is to let the fluid in the pipeline can only flow in one direction, can not let it return, so it is also called one-way valve. It works automatically.

- Q:Does FOTILE hood have check valve?

- If necessary, you can contact the aftermarket directly, technicians can bring home Oh ~!

- Q:Circulating water check valve, I want to ask is not greater than DN600, you can use HBH747H hydraulic butterfly valve closed butterfly valve, less than DN600 of HD43X slow butterfly butterfly check valve, what does hydraulic check mean? Need hydraulic?

- The opening and closing parts depend on the flow of the medium and the power is turned on or off by itself. The valve that prevents the backflow of the medium is called a check valveThis hydraulic pressure refers to the liquid pressure in the pipeline, not another pressure; the big caliber butterfly valves are small, and the small ones are all one-way valves. Another HB-HV hydraulic check valve, which is used on the oil circuit, the module and the operation circuit, you do not need.

- Q:What are the main types of check valves?

- Check valve structure of the main drop type, DL swing and butterfly, JB/T308 provides the structure code.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

high quality ductile iron cast iron flanged swing check valve

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords