CHECK VALVE LIFT RUBBER FLAPPER DIN DUCTILE IRON DN40- DN300

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Standard or Nonstandard: | Standard | Structure: | Check | Pressure: | Medium Pressure |

Power: | Manual | Material: | Casting | Temperature of Media: | Medium Temperature |

Port Size: | DN40-DN300 | Place of Origin: | China (Mainland) | Brand Name: | CMAX |

Application: | General | Medium: | Water, air, oil |

Packaging & Delivery

Packaging Details: | standard export packing plywood case |

Delivery Detail: | 30 days |

Features

● Rubber encapsulated disc

● Drain plug hole makes insertment of lifting equipment for flap possible

● Suitable for both horizontal and vertical installation

● FBE coated inside and outside

● Product color:Blue RAL5017

Technical Specification

● Flanges Drilling:EN1092-2 PN16

● Hydraulic test to ISO5208

Seat Test Pressure:17.6 bar

Shell Test Pressure:24 bar

● Maximum temperature:70℃

Materials

| Parts Name | Material |

| Valve body | Dutile iron, stainless steel, Cast Seel |

| Valve gland | Dutile iron, stainless steel, Cast Seel |

| Connection type | Flange connection |

| Application temperature | ≤80°C |

| Valve disc | Stainless steel+ nylon cloth wrap |

- Q:What is the check valve?

- Check valve, also known as one-way valve or check valve, its role is to prevent the medium back in the pipeline. Pump water off the bottom valve check valve also belongs to class.The opening and closing parts depend on the flow of the medium and the power is turned on or off by itself. The valve that prevents the backflow of the medium is called a check valve. Check valves belong to the automatic valve, mainly used for one-way flow of media channels, allowing only medium to flow in one direction, to prevent accidents.

- Q:What is the difference between globe and check valves?

- 1. check valve is called one-way valve, the role is to prevent fluid flow, can not be adjusted, can not be closed.2., the cut-off valve can be used to regulate flow, can be closed, can be closed.

- Q:What is the function of the check valve on the air compressor?

- Check valve is also called one-way valve, air will not go in only, can protect the air compressor host, if the air compressor main machine does not stop, you can not check valveIf it starts frequently, it must be loadedCheck valve bad consequences: motor overload, burn the host top off

- Q:Should the kitchen check be mounted on the wall or on the hood?

- Buy their own check valve is generally in the wall of the hole, the hood of the smoke machine, usually with a check valve.

- Q:Installation position of air pipe check valve

- Texture of material1. cast iron check valve2. brass check valve3. stainless steel check valve4. carbon steel check valve5. forged steel check valveCheck valve refers to rely on the flow of the media itself and automatically open and close the valve flap, used to prevent the media back flow valve, also known as check valve, Dan Xiangfa, counter flow valve and back pressure valve. The check valve belongs to an automatic valve, whose main function is to prevent the backflow of medium, prevent the reverse of pump and drive motor, and release the container medium. The check valve can also be used to provide a supply to the auxiliary system where the pressure may rise above the system pressure. The check valve can be mainly divided into swing check valve (rotating by gravity center) and lift check valve (moving along the axis).The function of this type of valve is to allow the medium to flow in one direction and to prevent flow in the opposite direction. Usually the valve is automatically work, fluid pressure flow in one direction, the valve open; the opposite direction of fluid flow by gravity, fluid pressure and valve closing effect on the valve seat, thereby cutting off flow.

- Q:How much is the check valve for the concrete pump?

- 31 concrete pump price ranging from 15W to 60W, different configurations have different prices, which one do you want?

- Q:There is a check valve at the inlet of Haier electric water heater to prevent water from flowing back. Because there are many hot water used in the house, should the hot water be fitted with check valve?Can the hot water outlet be fitted with check valves? The hot water pipe is too long for hot water to flow back into the heater... Is it possible to install two check valves to affect the normal use of the heater?

- No check valve can be installed. The check valve needs a certain amount of pressure to open. It may cause hot water flow or little hot water.

- Q:How can the check valve be distinguished from the cut-off valve?

- Turn on and off. Is the cut-off valve, can not turn off, open, automatic, in the middle of a plate will move, that is, check valve

- Q:What's the function of the small check valve on the deep well pump? Solve!When the deep well pump works, it does not move inside! Under great pressure! There is a hissing sound when the deep well pump doesn't work! The air is in! Will it lead to the water in the room? There's a lot of air in it!

- This valve is to stop the pump when the intake, through the intake of water to cut off the backflow, to prevent water from being returned to empty, the air can not enter the valve above the part of the water pipe, rest assured

- Q:How can the lift vertical check valve be distinguished from the lift horizontal check valve?

- The check valve is divided into three kinds: lift check valve, swing check valve and butterfly check valve. The lift check valve can be divided into two types: vertical and horizontal. Swing check valve is divided into single, double valve and multi flap type of three. Butterfly valve for the straight through, the above non-return valve can be divided into connection, flange and welding of three lift check valve and stop valve structure similar to the thread in the form of connection, the valve in a line along the channel for the lifting movement, reliable action, but the fluid resistance is large. Small in diameter for the occasion. Lift check valve can be divided into straight and vertical two kinds. Straight through lift check valve can only be installed in horizontal pipe, vertical lift check valve is usually installed in vertical pipe. You can see the picture in Baidu's picture

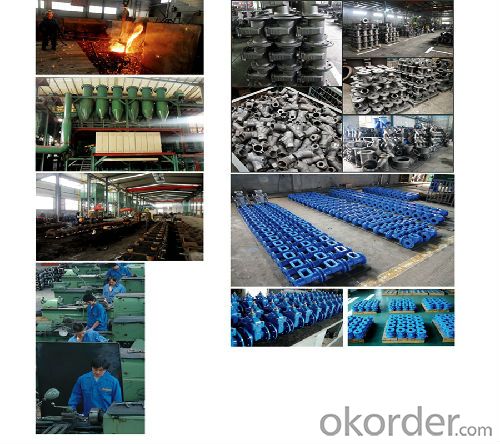

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CHECK VALVE LIFT RUBBER FLAPPER DIN DUCTILE IRON DN40- DN300

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords