CHECK VALVE WAFER TYPE DUCTILC IRON DN40-DN2000

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Standard or Nonstandard: | Standard | Structure: | Gate | Pressure: | Medium Pressure |

Power: | Manual | Material: | Casting | Temperature of Media: | Normal Temperature |

Media: | Water | Port Size: | DN50 | Place of Origin: | Tianjin China (Mainland) |

Brand Name: | CMAX | Nominal diameter:: | DN40-DN2000 | Working pressure:: | PN6/PN10/PN16/CL125/CL150 |

Valve Design:: | MSS-SP81 | Face-to-face:: | MSS-SP81 | Flange accommodation:: | ANSI;DIN ;BS ;JIS;GB |

Test Standard:: | MSS-SP81;API 598 |

Technical Date | Material Specification | ||

Nominal Diameter | DN40-DN1000 | Valve Body | Cast Iron or Ductile Iron |

Nominal Pressure | PN10/PN16 | Valve Disc | Cast Iron or Ductile Iron or Stainless Steel |

Operation Temperature | -40°C~225°C | ||

Flange Driling Standard | EN 1902-2 PN10/16 | Seal Material | EPDM OR NBR |

Suface Treatment | Painting | Valve Spring | Stainless Steel |

Application | Portable water, water distribution service & feed lines, sewage disposol, irrigation, fire protection pipe systerm, etc. | ||

Description:

Nominal diameter: DN50–DN2000

Working pressure:PN6/PN10/PN16/CL125/CL150

Valve Design: MSS-SP81

Face-to-face: MSS-SP81;

Flange Standard: ANSI;DIN ;BS ;JIS;GB

Test Standard: MSS-SP81;API 598;

Nominal Diameter DN | DN50-2000 | DN50-2000 | DN50-2000 | MM | |

Nominal Pressure PN | 0.6 | 1.0 | 1.6 | ||

Test Pressure | Seal test | 0.67 | 1.1 | 1.1 | Mpa |

Sheel test | 9 | 1.5 | 1.5 | ||

Working Tempertaure | -29~235 | ℃ | |||

Suitable Medium | Cement, Paper Pulp,Sewage,Water, Oil etc. | ||||

- Q:How to install industrial check valves? How should they be used?

- 1, straight through lift type check valve should be installed in horizontal pipe, vertical lift check valve and bottom valve is usually installed in a vertical pipe on the road, and the bottom-up flow of media.2, swing check valve installation location is not appropriate, usually installed in the horizontal pipe, but can also be installed in the vertical pipe or inclined pipe line.

- Q:The difference between check valve and check valve

- One way valve is also called a check valve, the two is the same kind of valve, meaning the same.

- Q:How does the check valve work?

- Check valve refers to rely on the flow of the media itself and automatically open and close the valve flap, used to prevent the media back flow valve, also known as check valve, Dan Xiangfa, counter flow valve and back pressure valve. The check valve belongs to an automatic valve, whose main function is to prevent the backflow of medium, prevent the reverse of pump and drive motor, and release the container medium. The check valve can also be used to provide a supply to the auxiliary system where the pressure may rise above the system pressure. The check valve can be mainly divided into swing check valve (rotating by gravity center) and lift check valve (moving along the axis).The function of this type of valve is to allow the medium to flow in one direction and to prevent flow in the opposite direction. Usually the valve is automatically work, fluid pressure flow in one direction, the valve open; the opposite direction of fluid flow by gravity, fluid pressure and valve closing effect on the valve seat, thereby cutting off flow.Among them, the check valve belongs to this type of valve, which includes swing check valve and lift check valve. The swing check valve has a hinge mechanism and a gate like valve free against the inclined seat surface.

- Q:The air pipe is equipped with a check valve

- The weight of the valve or the gravity of gravity to maintain the valve in the open state of balance, the principle of the same, are heavy torque control of the door opening and closing. Inside and outside the air pressure to destroy the balance, automatic door opening and closing control. An example of simply closing a valve plate by gravity, as in a vertical check valve (Dan Liufa) in a water supply pipe.

- Q:Installation position of air pipe check valve

- The air pipe check valve is installed in an air conditioner or a pipeline, and when the fan is in operation, the blade is lifted and the air flow passes smoothly; when the fan stops, the valve blade is closed, and the backflow of gas is prevented. But the wind speed in the air duct must not be less than 8m/s. (it can be made into explosion-proof type or pneumatic type)Check valve refers to rely on the flow of the media itself and automatically open and close the valve flap, used to prevent media backflow valve, also known as check valve, one-way valve, counter flow valve, and back pressure valve. The check valve belongs to an automatic valve, whose main function is to prevent the backflow of medium, prevent the reverse of pump and drive motor, and release the container medium.

- Q:Check valve in the water pump when the sound of vibration is very large, what is the matter?

- For the gas wall boiler heating system, the water from the water booster pump mouth must be installed on the gate for gas wall boiler heating system, water plus appropriate pressure to turn off the gas wall furnace, built in water supply valve, heating system, water flow

- Q:Circulating water check valve, I want to ask is not greater than DN600, you can use HBH747H hydraulic butterfly valve closed butterfly valve, less than DN600 of HD43X slow butterfly butterfly check valve, what does hydraulic check mean? Need hydraulic?

- The opening and closing parts depend on the flow of the medium and the power is turned on or off by itself. The valve that prevents the backflow of the medium is called a check valveThis hydraulic pressure refers to the liquid pressure in the pipeline, not another pressure; the big caliber butterfly valves are small, and the small ones are all one-way valves. Another HB-HV hydraulic check valve, which is used on the oil circuit, the module and the operation circuit, you do not need.

- Q:Should the flue check valve be made by the civil team or the installation team?

- Internal construction, check the inner ring outside the cement glue installed

- Q:What can I do with the lift check valve?

- With the structure of short length, small volume and light weight, the valve closed fast, water hammer pressure, flow smooth, fluid resistance small, horizontal or vertical pipe pipe can be used, easy installation, quick action, good sealing performance, the valve stroke is short, close the valve impact force is small, simple and compact, beautiful appearance, service life long, high reliability, to prevent the media back, the characteristics of automatic control. A lift check valve is used on an industrial pipe to prevent the flow of a medium.

- Q:What is the structure of the check valve of the screw air compressor?

- Work process: air pre filter, and then through the air filter and the air inlet controller into the mixing chamber and the compression screw lubricating oil, continuous linear by asymmetric rotor two, compression. The compressed oil and gas mixture enters the tank and the separation system for three levels of separation (centrifugal, self weight, and fine separation). The separated compressed air is discharged after the cooler is cooled, and a reliable pressure switch system controls the exhaust pressure. When the machine is running, the screw compressor run oil system by pressure difference automatic circulation, without pump. When starting, the minimum pressure valve is closed to ensure the minimum pressure required for the lubrication oil circulation. In addition to lubrication, the oil also acts as sealing, cooling and reducing noise. High efficiency oil and gas separator and high efficiency cooler ensure high quality compressed air.

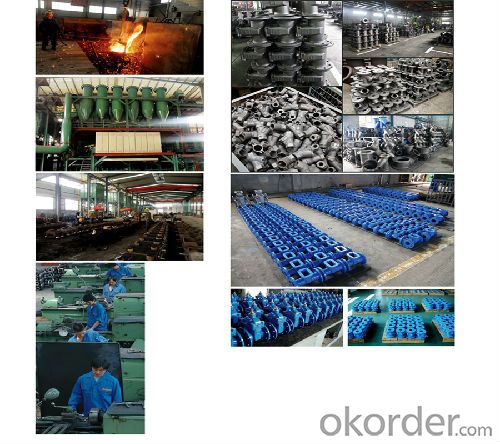

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CHECK VALVE WAFER TYPE DUCTILC IRON DN40-DN2000

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords