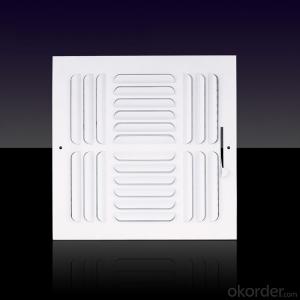

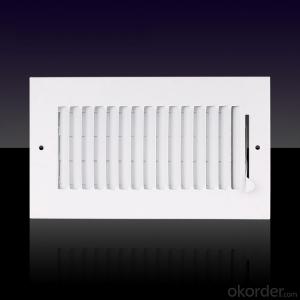

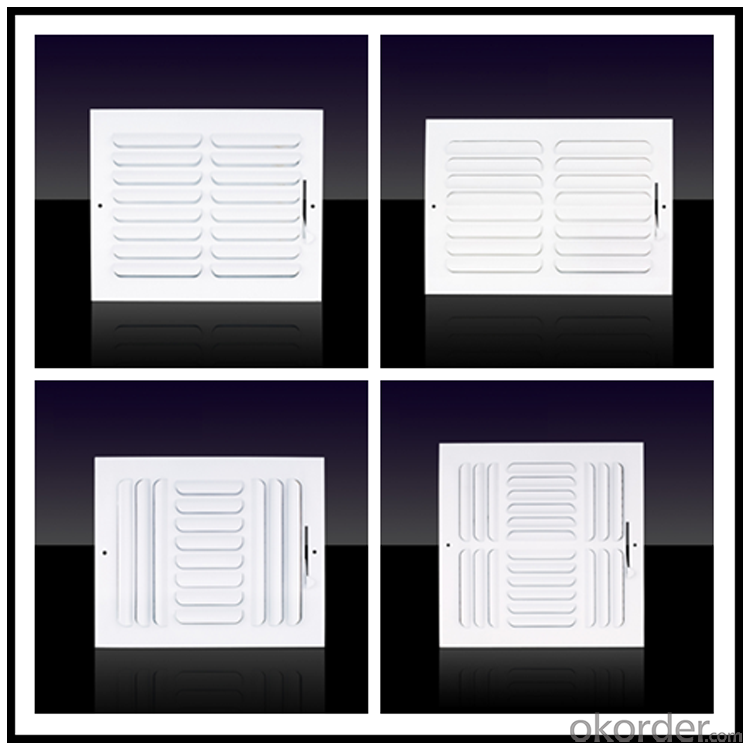

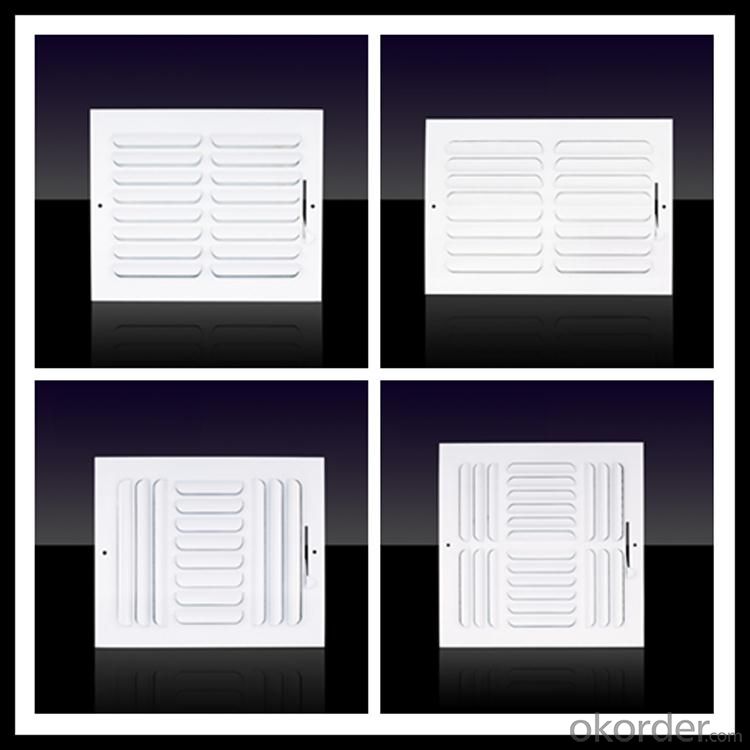

Cruved Blade Square air Vent Diffusers Factory Supplying

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 999999 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Air Diffuser

Supplying Air Diffusers

-Frame Thickness: 1.0mm /0.8mm

-Any Size be customed

-Powder Coated RAL 9010/9016

-1-4 curved blade air diffusers

Specifications

The grille is suitable for ceilling sidewall, soffit or cill mounting and may be used for supply or extract applications.

Typical installations include offices, shops, hotels and most commercial or industrial buildings.

Available as standard in white polyester powder coat finish.

Other polyester powder coat finishes are also available as an option.

1 | Item | HVAC aluminum air conditioner grille |

2 | Materials | Extruded Aluminum alloy (6063-T5) |

3 | Blade | Blades in 45°from aluminum profile or as customer’s requirements |

4 | Bar spacing | 30mm as standard or as customer’s requirements |

5 | Materials | 0.8mm, 1.0mm, 1.2mm, 1.5mm or according to the customers’ |

6 | Surface Finish | Powder coated, Anodized , PVDF, Mill finish. |

7 | Size | Width x Height, any sizes available |

8 | Powder for Finish | Environmental protection and non-toxic, and Color to keep 5 -10 years. |

9 | Color | Refer to RAL colors swatch or customized colors available |

10 | Design | Drawings designed according to the customers’ requirements |

11 | Payment terms | T/T, L/C, PYAPAL, etc. |

12 | Delivery time | Usual 15-20 work days for a 40GP container |

13 | Package details | Bubble wrap + Cartons for FCL, Bubble wrap + Cartons + Wood-box for |

14 | Mesh | Stainless steel security mesh, Aluminum security mesh |

15 | Type | Fixing and adjustable installation |

Products show

Production line

FAQ of Air Diffuser:

1, What's size do u have for round type diffuser?

A: We have face size from 150mm to 550mm,neck size from 250mm to 400mm聽

2, Do u still have other types ?

A: Yes, we have round diffuser/ rectangle diffuser/ linear grilles/ baseboard diffusers,etc

3, What's the most early delivery time?

A: Within 25 days for each 40'fcl

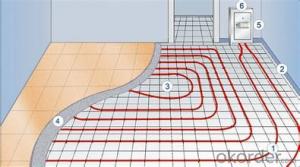

- Q:Pavement should pay attention to what the details,

- Uniform and no leakage!

- Q:To warm the accessories 3 / 4m * 16 * 20 what meaning

- 1620-3 / 4 that side of the 6 sub-tube, the other side is 6 teeth

- Q:Wooden doors how much temperature will be deformed

- 85 ~ 95. Wooden door is the use of ultra-fine wood powder and polymer resin mixture, made by the molding process, both wood and plastic excellent characteristics, the production of products to achieve the effect of real imitation wood. As the use of raw materials and production processes do not use glue bonding, will not produce formaldehyde, benzene, ammonia, trichlorethylene and other harmful substances, is a substitute for traditional wood green new materials. The main raw material of wood-plastic doors is PVC resin and high-quality wood powder, PVC resin using domestic medical grade brand-name products, wood powder by the professional wood company to provide high-quality wood powder, after grading screening, grinding, drying, Finished product on the quality requirements of raw materials. Wood-plastic door system with a certain proportion of auxiliary materials, adding stabilizers, foaming agents, modifiers, etc., a variety of ingredients according to strict mixing ratio, effectively guarantee the quality of foam sheet products. Wood-plastic door production equipment has a mixing system, extrusion system, a high degree of automation, which mixing equipment with the amount of ingredients accurate, mixed evenly, high efficiency, fundamentally to ensure the stability of the product. As the production of wood-plastic foam door production of foam extrusion equipment requirements are higher, the use of high-torque twin-screw extruder, and screw, screw and other components to transform to meet the lignin inside and outside the surface crust and uniform hair Soak, to avoid charcoal charcoal and other phenomena occur. Wood-plastic doors using thermal transfer process, in the extrusion of the plate on the transfer of various graphics, the product has a variety of high-grade tree grain and color, according to the market popular varieties to design to meet the needs of modern consumer life personality.

- Q:I see the panel has a "cycle of digital time relay", the United States called microcomputer controller, as well as seismic pressure gauge, the rest is the switch indicator light, and there is no knowledge of what (estimated that there are two A solenoid valve a tube of water a gas), this thing on the market to sell more than 2000, I feel the cost of 200 to 300 yuan (guess, because I do not know where the burden of the child to pay the nuclear shop is too much money). Hope to tell the internal structure, which there are any components, I would like to do one, have a better picture, as well as cleaning, "time relay" set parameters (water and ventilation time), hope you greatly educated, brother Thank you The More

- come on, come on, come on

- Q:What is the service life of the air source heat pump water heating system?

- Air source heat pump water to warm the general service life of up to 50 years or so, but if in daily life without reasonable use, will certainly cause water to warm the service life is shortened, so we use water to warm when appropriate to use, and do not forget The water to warm the corresponding maintenance. Carry out the necessary periodic inspection of water to warm the system mainly by the insulation facilities, sub-catchment, geothermal system, pipeline valves, backfill concrete composition. Among them, the sub-catchment has shunt, collecting, constant pressure, exhaust and so on. Therefore, the sub-catchment installed directly affects the quality of the project and the quality of heating. Scale, material, installation and other factors will affect the role of the water separator, if the above factors are not well resolved, there will be leakage, the pipeline longitudinal cracking, valve off and so on. These phenomena often appear in the upper and lower bar of the water divider interface, the angle valve and the main bar connection, the angle valve handle, and the exhaust valve at the top and the root. This phenomenon will generally occur in the water to warm the system used a year or two later. Therefore, the water to warm the system in the use of a year or two later, the user in their daily lives should pay attention to regularly check their own water to warm the system to prevent such phenomena in time to produce. Check the method can follow the "one look, two screw, three pull" principle

- Q:What is the warm lead of the heating cable

- This is a kind of special sea ridiculed guest Curcuma Jiufeng after the end of the processing of the cable, belonging to the temperature control class of metal parts. When the room temperature is below the set temperature, he will be connected to the current, so that the heating system to run, generate heat to know to set the temperature.

- Q:We have two or three years useless to warm, the annual temperature is about 23 degrees. This year is still not hunger view spy grab the silicon oblique helmion want to, do not know the ground heating facilities have no harm, need to pay attention to what? Question added: water to warm, thank you! More

- Nothing to worry about, to warm the dark tube, plastic pipe are used for at least 50 years. The best water to let go.

- Q:Want to shop to warm, the designer recommended Bosch boiler, but friends say camel to warm more standardized, tangled! Which one should I choose?

- Water to warm by the heat source, the ground auxiliary material, the control system and so on, you say the Bosch boiler can only warm a component, you choose the camel to warm, the flower lamb of the barley tibble can also let their designers help You choose Bosch Boiler ah, do not conflict ah

- Q:What parts of the radiator (radiator) heating system?

- In simple terms, the radiator (radiator) heating system consists of: heating water heater, heating pipe, radiator and thermostat composed of four parts. Specific questions can be consulted at any time.

- Q:What is carbon crystal and carbon fiber?

- What is carbon crystal and carbon fiber?...

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cruved Blade Square air Vent Diffusers Factory Supplying

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 999999 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords