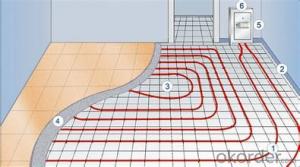

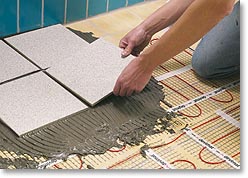

Ceramic Tile for Flooring Heating System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 3000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Ceramic tile for floor heating system.

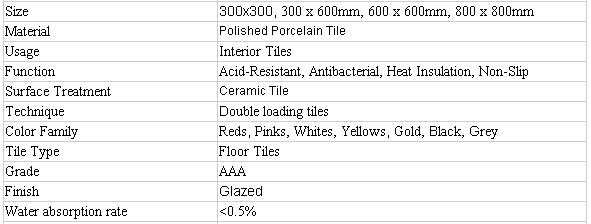

Specificaiton:

Features

1. All products are top grade of ceramic Tile

2. CE certificate, ISO9001

3. Special size available according to request.

4. Best Quality with best price, strictly quality control.

5. Delivery on time

6. Best after sale service, customer can follow their order situation any time, no matter on product line, warehouse or shipment.

7. Small order accepted.

8. Feature: no fading

Photo:

FAQ:

① why from okorder?

Okorder is a qualified supplier of all kinds of building matierials in China. All products have been showed in Okorder website are under well controlled by okorder QC team.

All products had been produced under a clear quality standard and the quality is consistence among the shipments.

Okorder has already setted up more than 20 warehouses in different markets to show the products. You are convenient to know the products from your local place and it will help you to make decision easyly.

②How to guarantee the quality of the products?

We have established a perfect quality management system,as for raw material and semi parts all are under strict quality test and we have a IQC system to control the purchases.

QC on site is very strict and all steps of process are measured per drawings. Before delivery, we set a OQC system to make sure each piece meet the standard of order.from design to delivery,

③How long can we receive the product after purchase?

Lead time depending on order quanity, The normal order can be deliveried with 3 weeks.

- Q:Bathroom heating tube plus wall-mounted small basket, what spare parts? What are the requirements of the connection, are directly from the bottom into the impact of hot effect?

- If your small back baskets with the warm system is connected in parallel with the accessories: tee, elbow, live one, the valve one, the role of the valve is mainly to control the flow, such as the accumulation of arms forging brace boxing The way you do not have a valve, with two live access

- Q:Home to use to warm, but want to use Finney's cooling water heater, do not know how to combine?

- To warm the general use of fireplaces, water heaters for life hot water, does not affect. If you want the two sets, it involves the system integration, and need to see your system and want to achieve the function to match the controller and control valve, and for the HVAC professional is not a complex State sleep pumpkin mixed, but do not understand or very hard....

- Q:What is the principle of warm What do the fuel

- What is the principle of warm What do the fuel...

- Q:To warm only part of the room, do not open the room will freeze it?

- Winter is not open to warm, the tube is not necessarily frozen. There are three kinds of heat to the ground: boiler, air source host, ground source heat pump host. ① boiler installed indoor, the ice may be very low, this situation can not be frozen ② use of air source, ground source heat pump to provide heat source, the host In the outdoor may be frozen, the two heat sources in the ambient temperature below 3 ℃, will automatically open the antifreeze function switch, the professional installation company will be installed in the system, antifreeze, lower ambient temperature will not appear Icing phenomenon.

- Q:How long can I use water? How much does it cost each month? Which is the most professional to warm?

- If you buy, once Yong Yi, spend Well ~ all around the same,

- Q:What is the basic task of heating engineering? The heating system is composed of some parts

- The basic task of heating engineering is to meet the needs of the heat load components: heat, heat, hot users

- Q:Which brand is good to warm the mixer?

- Tsinghua Tongfang

- Q:My house in 2004 the house, an area of 35 flat, small layer, the second floor (downstairs garage), geothermal building comes with, and now the heat is not hot, home temperature also 12-13 degrees, is the district property heating, looking for They have to put a few times the water, but also no effect on the door neighbors say that we are almost home and upstairs, 8th floor neighbor said that there are 17-18 degrees home, I would like to know, what is the reason? Geothermal cleaning company to clean the sea and OKorder fucking cough cough Feng anchor, cleaning once can improve the number of degrees will not heat the bad ah? If there is cleaning the heroes, recommend a better cleaning of the geothermal cleaning company. many

- Lalala

- Q:To install the mixed water center also installed with a pressure differential bypass valve

- Mixed with a pressure valve is not?

- Q:Whether the groove card can be used for heating pipes

- Not suitable for the groove in the gasket is rubber material heat resistance is not high long-term thermal environment will cause the gasket aging caused by leakage

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceramic Tile for Flooring Heating System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 3000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords