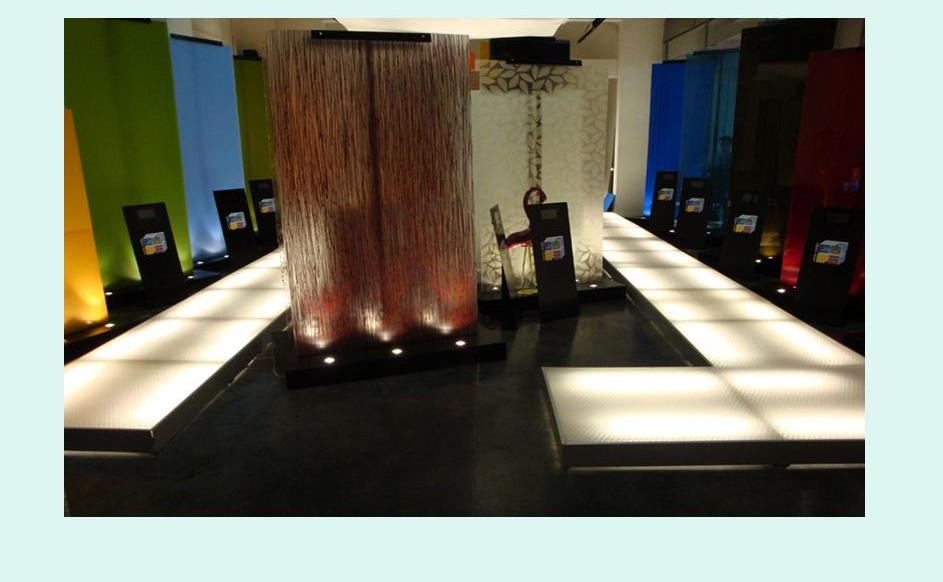

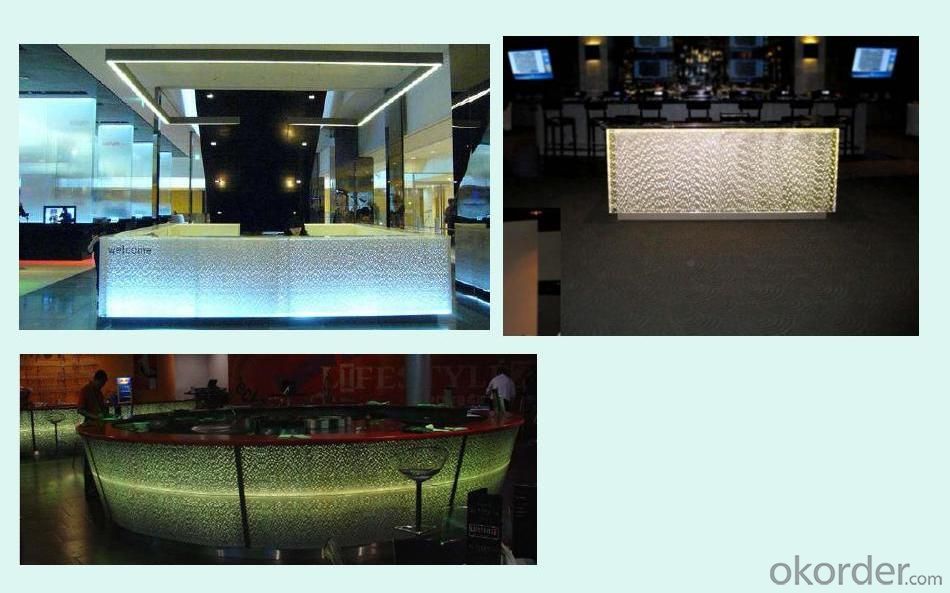

CMAX Resion Natural Panel make your shopping mall Reception

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CMAX Resion Natural Panel make your shopping mall Reception

Eco-friendly: Cerified LEED credits, Fully Recycled, Nontoxic.

Light Weight: Half of density of Glass, easy to installation.

Safety: High level of anti-firr. non-broken

Chemical Stability: Good resistance under chemical contact, anti-aging with UV protection, HDT (Heat Deflection Temperature) can be up to 85 degree.

Mechanically formaing: Post-formable into virtually any shape or size without blushing and cracking.

High surface hardness: anti-scartch.

Properities: High gloss and transparency (up to 93%).

Specification:

Panel Materials:PETG

Fire Rating:B1 or C

Thickness: 3mm,4mm,6mm,10mm,15mm,20mm,25mm,30mm,or customized

Color: Optional

Facing Finish: Glossy, Satin

Size: 1200*2400mm

1200*3000mm

FAQ:

1. Where is your factory located in?

Our factory is located in Jiangsu Province, close to Shanghai Port.

2. Can we order LCL and what is MOQ?

MOQ is 50 pcs for each item, LCL is acceptable.

3. Can we get samples before making order?

Yes, we can provide you a small size sample for free.

- Q:Can plastic sheets be used for decorative lampshades?

- Yes, plastic sheets can be used for decorative lampshades. They are versatile materials that can be molded into different shapes and designs, allowing for creative and unique lampshade designs. Plastic sheets also offer the advantage of being durable, lightweight, and easy to clean, making them suitable for decorative purposes.

- Q:What is the lifespan of plastic sheets?

- The lifespan of plastic sheets can vary depending on various factors such as the type of plastic, exposure to sunlight, temperature fluctuations, and overall usage. However, plastic sheets can typically last for several years to decades if properly cared for and maintained.

- Q:Are plastic sheets safe for children?

- Plastic sheets can be safe for children, but it depends on the specific material and how they are used. It is important to ensure that the plastic sheet does not contain harmful chemicals, such as phthalates or BPA. Additionally, adult supervision is necessary to prevent children from suffocating or getting entangled in the sheet.

- Q:Why build a house with plastic foam?

- The foam board used for exterior wall insulation is called polystyrene foam board.Polystyrene foam board, foam board, also known as the EPS board is composed of expandable polystyrene beads containing a volatile liquid foaming agent, the white object heating molding in the pre heating, the structure characteristics of the tiny, mainly used for building wall, roof insulation, composite insulation board, cold storage, air conditioning, vehicles, ship insulation, floor heating, decoration carving is widely used.

- Q:I got the thick 4mil, does it work better with a space between the window and film? My neighbor puts the film right on the window, does that help? I think a still-air space would work better. How much does it really help, 5%?

- You are correct that an air-gap would provide much better insulation than the film directly in contact with the window, and, I would expect it to improve your heating expenditures by no more than about 15% or so.

- Q:How to hang the net on the cement board, stick the wall tile (is the barbed wire or the plastic net) with the benzene plate glue?

- My way is to use cement workers fixed nail and then painted tiles. See wall quality whether ceramic tile adhesive?! Hope to adopt!

- Q:What is an extrusion plate?

- Extruded board, fully extruded polystyrene foam board, referred to as Extrusion board, also known as XPS board. The polystyrene resin and polymer are used to heat the mixture and inject the catalyst. Then, the rigid foam board with continuous closed cell foaming is extruded.

- Q:In the home decoration inside, acrylic panels and ordinary plastic panels what is the difference?

- Organic glass acrylic and special processing, organic glass products, light boxes with acrylic production has good transparence, pure color, rich colors, beautiful smooth, both day and night of two kinds of effect, long service life, does not affect the use of the characteristics of the stress, compared to ordinary plastic panel and the panel

- Q:Company wants me to pay extra for it but why do I need it?

- Moisture, vegetation growth, radon. Many good reasons for it. Make sure it's air/water tight, no rips and the seams are taped with proper sealant tape. The higher mill the better. I think it's at least 6 mill. Pay attention and don't let them cheat you.

- Q:I'm curious how plastic sheets/boards are made. The kind that may possibly be found at places like Home Depot.. I have an inkling that the sheets are extruded and cut into boards.. but I need a confirmation of this process. It would help greatly!!Is there a site that can explain this process?Any advice helps and is greatly appreciated. THANKS!! :)

- Plastic sheets / tubes of longer length are produced by extruding. Smaller sizes by moulding.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CMAX Resion Natural Panel make your shopping mall Reception

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords