Dental Floss Bamboo Charcaol Food Grade ISO CE Tooth Floss

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 box

- Supply Capability:

- 100000 box/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Dental Floss Bamboo Charcaol Food Grade ISO CE Tooth Floss

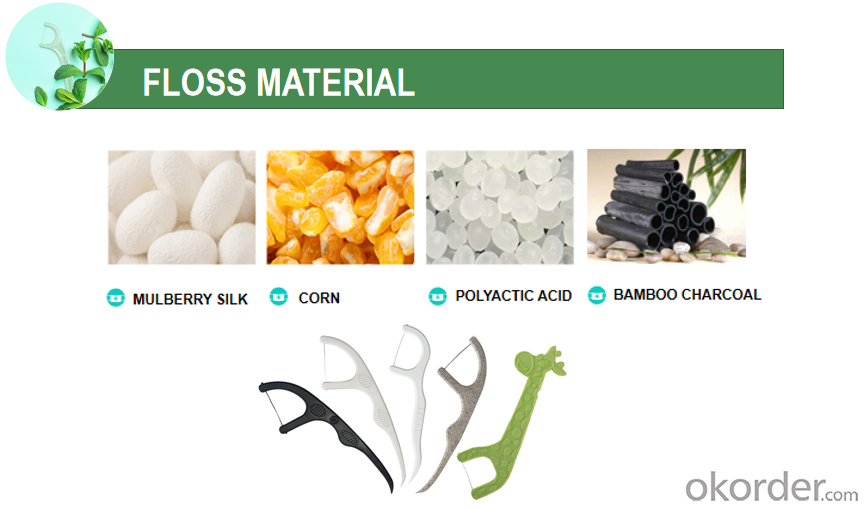

| Brand | OEM/Ok Floss |

| Floss material | Bamboo Charcoal /OEM |

| Floss length | 7.4*2.2cm/OEM |

| Wax | Import germany wax/american wax/bee wax/candelilla wax/customized wax |

| Flavor | Mint / green tea / lemon / peach / fruit / aloe / gin |

| Color | Black |

| Floss original color | Individual bulk PP bag/individual paper box/as customized |

| Applications | Family,Hotel,Travel,Supermarket |

| Delivery | By sea,By air,By express. |

| Lead time | 20-30days |

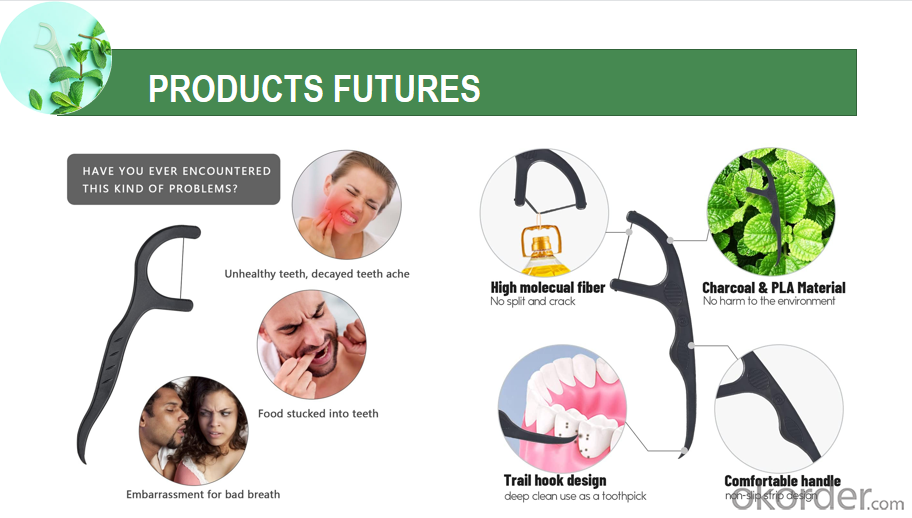

Soft tape to ace the tight space

No break, no shred floss

Helps remove plaque between teeth

Helps prevent gingivitis between teeth

Unique handle design, makes it easy and comfortable to floss. Removes trapped food debris.

Extra bristled pick for hard to get bits,even gets behind hard-to-reach molars.

Gently slides smooth between tight teeth. Freshen breath with flavor.

Recommends you use OK flosser after every meal and snack to have a fresher, cleaner mouth. For a completely daily clean, use with a OK flosser to easily reach back teeth.

OK FLOSS HELP YOUR ORAL CARE PROFESSIONAL OEM/ODM PROVIDER

Why we need use dental floss??

Because it can reduce your chances of 60% of adjacent dental caries and 70% of periodontal disease. It allows you to have a healthy tooth of your own at

the age of 80.Flossing your teeth in the right way will remove food particles and growing plaque from spots where your toothbrush can’t reach, generally

between your teeth and under the gumline.

Suggested use

Directions for flossing: While holding the handle, gently guide the floss between your teeth using a zig-zag motion. Move floss away from the gumline in a gentle back and forth, up and down motion alongside each tooth to remove food particles and plaque. Rinse floss as needed and repeat for each tooth.

Warnings

Adult supervision recommended under age 10.

FAQ

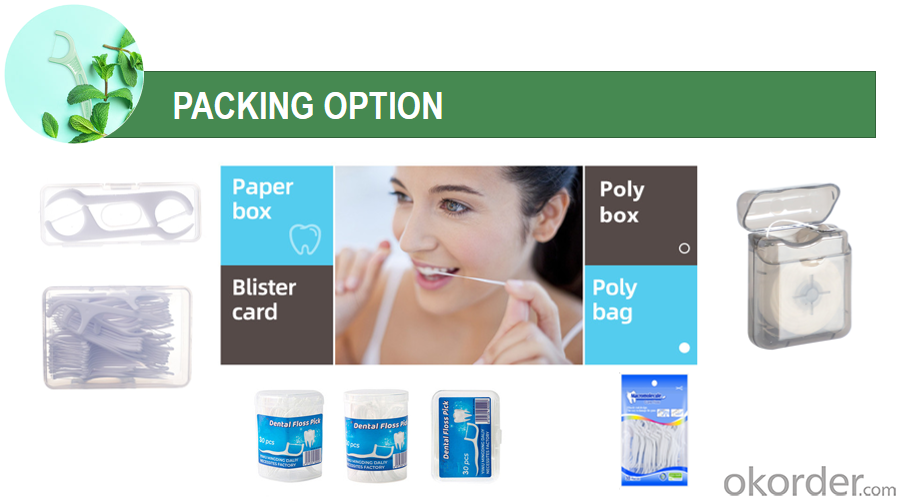

Q: Can you accept OEM make?

A: Sure.We can make your customized brand and design blister card, inner box and master carton, and also pack as per your request.

2. Q: Where can I put my logo?

A: We can print your logo on the sticker, blister card, inner box and master carton.

3. Q: What are your MOQ?

A: Blister card packing: 10000 pcs/item.

Bulk packing: 5000 pcs/item.

4. Q: How can I get Samples?

A: Samples are free, while the shipping cost to be collected.

5. Q: What are your terms of payment?

A: 1) T/T(30% in advance, the balance by the copy of B/L).

2)For small order less than USD 3000, in order to save bank commision for both of us, we need 100% in advance.

6. Q: How long is the delivery time?

A: For the MOQ, the leading time is about 20-30 days.

- Q:How is medical plastic used in surgical implants?

- Medical plastic is commonly used in surgical implants due to its biocompatibility, durability, and versatility. It is used to create various components of implants such as screws, plates, and joints. These implants are designed to replace damaged or diseased body parts, providing support and restoring functionality. The use of medical plastic in surgical implants helps to minimize the risk of rejection or allergic reactions, and it also allows for better customization and ease of surgical placement.

- Q:How does medical plastic contribute to infection control in healthcare settings?

- Medical plastic contributes to infection control in healthcare settings in several ways. First, it is often used in the manufacturing of single-use medical devices such as syringes, catheters, and IV sets, which reduces the risk of cross-contamination between patients. These devices are disposed of after a single use, minimizing the chances of spreading infections. Second, medical plastics can be easily sterilized using various methods such as autoclaving or gamma radiation. This ensures that the devices and equipment made from medical plastic are free from harmful microorganisms, preventing the transmission of infections. Furthermore, medical plastics are designed to have smooth surfaces that are resistant to microbial attachment. This makes it harder for bacteria or viruses to adhere to the surface, reducing the likelihood of infection transmission. Lastly, medical plastics are often used in the production of personal protective equipment (PPE) such as gloves, gowns, and face shields. These materials provide a barrier between healthcare workers and potential sources of infection, offering an additional layer of protection. In summary, medical plastic plays a crucial role in infection control by providing disposable, sterilizable, and resistant materials for the production of medical devices and PPE.

- Q:What are the factors that affect the electrical conductivity of medical plastics?

- Some factors that affect the electrical conductivity of medical plastics include the type and composition of the plastic material, the presence of additives or fillers, the temperature and humidity conditions, and the surface properties of the plastic. Additionally, the presence of impurities or contaminants can also impact the conductivity of medical plastics.

- Q:How does medical plastic help in minimizing the risk of device-associated infections?

- Medical plastic helps in minimizing the risk of device-associated infections by providing a non-porous and easily cleanable surface that can be effectively sterilized. It also offers excellent chemical resistance, preventing the growth of bacteria and other microorganisms on medical devices. Additionally, medical plastics can be designed with antimicrobial properties, further reducing the risk of infections.

- Q:What are the methods of disinfection and sterilization of medical instruments? Plastic products can not be sterilized at high temperature. What is a good way to do this?

- Ethylene oxide is difficult to transport, so you can see the supply locally. If you do not have the ability to disinfect, you can also find medical equipment company oem.

- Q:What are the advantages of using medical plastics in healthcare?

- There are several advantages of using medical plastics in healthcare. Firstly, medical plastics are lightweight and flexible, making them easy to handle and manipulate during medical procedures. Secondly, they are highly resistant to chemicals, ensuring the safe storage and transportation of medications and other medical supplies. Additionally, medical plastics have a low risk of contamination, as they can be easily sterilized. This helps in maintaining the highest standards of hygiene and preventing infections. Moreover, medical plastics are durable and long-lasting, reducing the need for frequent replacements and saving costs. Lastly, they are also transparent, allowing healthcare professionals to monitor patients and procedures effectively. Overall, the use of medical plastics in healthcare improves efficiency, safety, and patient care.

- Q:How is medical plastic used in wearable medical devices?

- Medical plastic is used in wearable medical devices to provide a lightweight, durable, and flexible material that can be easily molded into various shapes and sizes. It is used for components such as straps, bands, and casing, ensuring comfort and ease of use for patients. Additionally, medical plastic is biocompatible, meaning it is safe to be in direct contact with the skin for extended periods, making it an ideal choice for wearable medical devices.

- Q:What about plastic pipe material?

- Metal composite plastic pipe: steady pipe (polyethylene, polypropylene and aluminum belt), aluminum plastic pipe (polyethylene aluminum belt or aluminum pipe), steel plastic composite (steel pipe or steel wire or steel band composite polyethylene).

- Q:Can medical plastic be safely used in tele-radiology applications?

- Yes, medical plastic can be safely used in tele-radiology applications. Medical plastic materials used in these applications are specifically designed to meet the necessary safety and regulatory standards. They are chosen for their durability, non-reactivity, and ability to withstand the required sterilization processes. Additionally, medical plastic is lightweight and can be easily cleaned and disinfected, making it suitable for tele-radiology equipment used in remote healthcare settings.

- Q:How do medical plastics affect the performance of medical equipment?

- Medical plastics play a crucial role in enhancing the performance of medical equipment. Due to their unique properties such as biocompatibility, durability, and flexibility, medical plastics are extensively used in various medical devices. They contribute to improved functionality, reduced weight, and increased patient comfort. Additionally, medical plastics enable the development of advanced technologies like minimally invasive surgical tools and imaging equipment, thereby revolutionizing healthcare delivery.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Dental Floss Bamboo Charcaol Food Grade ISO CE Tooth Floss

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 box

- Supply Capability:

- 100000 box/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products